Testimonials

"In our KIWI biolab, the BioXplorer 100 has been integrated into a fully automated experimental setup to generate high-resolution data from microbial bioprocesses, with experiments running for up to seven days. Acting as the core of the automated setup, the BioXplorer 100 enabled a flexible experimental workflow, supported by the integration into a Tecan liquid handling station, integrated off-gas analysis, and connectivity via a mobile assistant to high-throughput analytics (Cedex and 2D HPLC-QTOF). The all-in-one solution provided by h.e.l., embedded within the robotic framework, has been extremely valuable. We were able to seamlessly integrate the system into our existing laboratory infrastructure and significantly expand its functionality. In particular, the immediate and highly responsive technical support - including customized software and function extensions - has been very helpful. The high-throughput capabilities of the system have enabled us to efficiently screen a wide range of experimental conditions for microbial bioprocesses."

KIWI biolab - TU Berlin, Germany

"My experience with H.E.L dates since 2005. During these years H.E.L was the provider of the most important lab equipment with the help of which I developed many different API pharmaceutical processes in the companies l worked for including Merck, Pfizer, and Theravance. The versatility of the automated lab reactors (AutoLAB), the ease of use of and the accuracy of the TSu and Simular systems, as well as the flexibility of the PolyBLOCK made my work much easier and accurate. I would like to mention the great relationship I established with the service engineers and the sales people at H.E.L. With their help I was able to customize the software and the hardware of the equipment to our specific needs. This readiness to accommodate each customer’s specific needs gives H.E.L the edge over their competitors and makes them the preferred vendor for pharmaceutical lab equipment. "

"I use a H.E.L. turbidity probe plus temperature probe for the determination of metastable zone widths and latent/induction time measurements in the study of crystallisation behaviour. The system is easy to use and very robust and records faithfully all the happenings. Even if one manages to do silly things, the data is still there and recoverable. The probes are neat and so can be used in small vessels, an advantage when dealing with valuable compounds. The amount of data that the computer will hold from a run is astonishing. The help from the technical team is always there, so we have been very pleased with our purchase. "

"With the polyblock 4 system significant time savings have been achieved compared to using conventional laboratory reactors while at the same time obtaining more information on the process studied. The system has given reproducible process control making it very useful in DOE experiments on a precise recrystallisation where variations due to operational error had to be minimised. Also with the flexibility in reactor size the process was run on smaller scale than previously reducing the demand for a valuable process intermediate. "

"A versatile time saving tool for QBD & DOE study for all kind of chemistry, crystallization, & even integrated with Calorimetric study. H.E.L motto “Better Chemistry – Faster” matches with output of instrument giving better control over chemistry & faster result. Thanks for making our work simple."

"We purchased a PolyBLOCK 4 zone system in November and the system was delivered on time and to our specification. The PolyBLOCK has increased throughput by allowing us to easily and efficiently run multiple reactions. Our system has proven to be very reliable and we utilize it on a daily basis. We are very satisfied with our purchase of the PolyBLOCK 4 and the advice and technical support offered by HEL. "

"PolyBlock PB4 is ideal and best suited for Pharmaceutical application in terms of flexibility, upgradability for various applications like pH monitoring and control, solubility and MSZW for crystallisation , high pressure Hydrogenation , Online Real Time calorimetry, reflux & inerting , PAT tools in future , overhead motor stirring , extended temperature range -80 to 250 ( depends on the chiller being used with the PB4 )."

Dr D.Y. Patil - Institute of Pharmaceutical Sciences – India

"The PolyBLOCK 4 is simple to use for all chemists and biochemists in our company. It allows us to carry out more reactions at a time, under very good temperature control. We also operate the PolyBlock overnight under pre-programmed procedures, to save a lot of precious time. We use different sizes of glassware in the same block, which allows us to investigate our chemistry at small scale, and then scale-up using the same equipment and pre-programmed procedure."

BioCompatibles UK Ltd – United Kingdom

"We are happy to confirm that H.E.L has supplied us with two high pressure reactor systems with automation. These systems are used for the screening of catalysts and/or different reaction conditions in hydrogenation and hydroformylation reactions. We have been using one device with eight autoclaves during the last 8 years or so, and we are very satisfied with it. The handling and programming is quite easy. The graphical evaluation of data allows us to get an overview about the process in each autoclave. The cooperation and service provided by the employees by phone or e-mail is plain sailing. It is for this reason that we bought a second HP ChemScan with four autoclaves in 2010 which was upgraded recently to an eight-autoclaves-device. It allows a larger variation of parameters and also the graphical evaluation of the results has been further improved. "

"H.E.L has supplied us with high pressure reactors with automation which are working well and on the basis of this we are willing to recommend H.E.L for such systems."

Watson Pharma – PVT

"We received the ordered parallel high pressure system, everything is working well. Training and instructions were good and we are very satisfied."

"My role within the Green Chemistry Centre at the University of York (UK) is as Clean Synthesis Technology Platform Leader. Through this role I am currently supervising work being undertaken studying the application of heterogeneous catalysts and high-pressure gases for the conversion of biomass derivable compounds. As such our group has recently purchased three high-pressure reactors from H.E.L Ltd. To assist in the evaluation of our heterogeneous catalysts it is vital that stirring in the reactor vessel is control effectively and the reactor designs from H.E.L Ltd. achieve this by use of a suspended stirrer-bar system. As a result of our gas addition requirements some modification to the standard reactor designs were necessary, this being an area that H.E.L Ltd. were especially helpful in catering to our needs. From first contact with H.E.L (via Andrew Coleman), through reactor design and finally to reactor delivery H.E.L Ltd have been a pleasure to work. Throughout our interaction H.E.L Ltd. has proven to be knowledgeable, inventive and very efficient in supporting our research needs. I wholeheartedly support H.E.L Ltd. as a reliable, affordable, professional and helpful company for the design and manufacture of high-pressure equipment, and I certainly intend to use them again when such services are required. "

"The H.E.L FlowCAT is a very robust, compact and flexible apparatus for high pressure heterogeneous catalytic processes. Its small footprint and versatility, along with the advantage of having reliable safety features, make the H.E.L FlowCAT an excellent piece of equipment to use. It has impressive potential for scaling up procedures."

"Cranfield University is working with H.E.L group on the design and manufacture of custom automated synthesisers for production of artificial ”Plastic Antibodies”. By combining the expertise from Cranfield University on the synthetic process with automation and custom fabrication know-how of H.E.L, a range of synthesisers were produced, including a new near-production prototype. Our experience with the new automated reactor/synthesiser showed that it can perform reproducible synthetic cycles under controlled conditions and with minimal operator input."

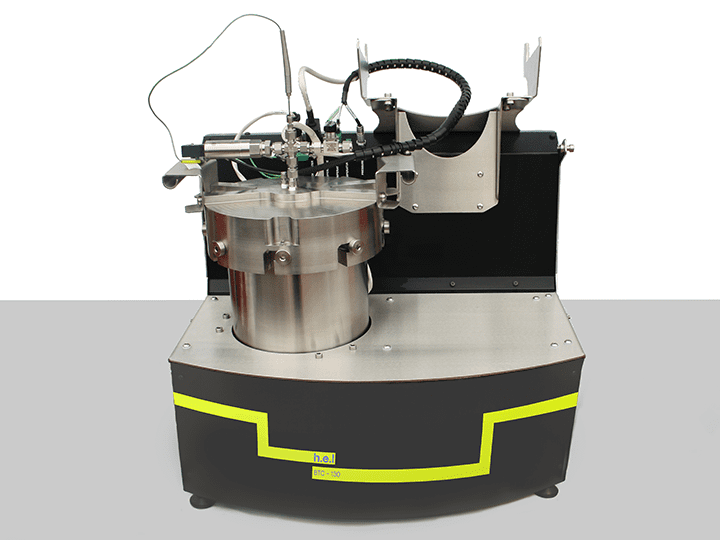

"We at TUV Rheinland consider ourselves to be quite fortunate in finding a vendor like H.E.L as the supplier of our Adiabatic Battery Testing Calorimeter. Not only does HEL provide a dynamic, but also a flexible team to work with. H.E.L’s expertise and experience in calorimetry has proven to be one of their strongest assets. The joint partnership with H.E.L has enabled us to develop services from which our company and our customers have benefited. We feel this BTC system has been a key factor to the success of our laboratory."

Japan - TUV Rheinland Battery Laboratory

"Three years ago we were developing a new catalytic process in collaboration with an industrial partner. It was essential to commission a reliable battery of glass reactors, built to our exact specification. We have decided to choose H.E.L’s AutoMATE II batch reactors array. We received professional advice, reactors built to specification, and a very thorough on-site training. The associated software is very intuitive and user-friendly. All issues occurring during the intensive use of the equipment were resolved quickly by the very helpful team at H.E.L. Last year, we have successfully progressed to a scale-up phase, for which we commissioned a custom-build AutoLAB reactor, with two exchangeable reaction vessels. Again, on all stages of ordering, manufacture and operation of the new reactor, the H.E.L staff were very helpful and made sure that their product was best suited to our needs. "

Belfast, Northern Ireland - Queen’s University

"I have to compliment the project manager. She handled the installation and on-site training very professionally. It was so nice to have a person that truly understands the system/product that is being installed. The overall support and advice from H.E.L was very good and we cannot be more satisfied with this or with the reactor itself."

Wildlife Pharmaceuticals - South Africa

"As a research active faculty member at Qatar University in chemical engineering with research fund that has a limited lifetime, I searched for specialist reactor suppliers around the world who would not only sell but also advise customers on their specific needs for the budget available. I was fortunate to select H.E.L in the UK and it started with an email query on a glass reactor for a tricky reaction system. That email was followed by a series of phone conversations to identify accurately my needs within my budget. I was particularly impressed by the speed of response and honest, impartial advice. I got what I wanted and when my research assistant encountered issues with the equipment during the warranty period, the spare parts were shipped very quickly, thus saving my research team precious time. H.E.L staff are professionals and trustworthy. As a research professor, I definitely recommend H.E.L for queries and purchases for intricate glass reactors for serious research work"

Qatar University - Doha, Qatar

"This apparatus has many advantages. You have a good control of the temperature and pressure and you can follow the gas uptake on the monitor with good accuracy. The software is easy to use, with all commands for one run resumed in one program. The interface of the software is pleasant looking with a good view of all parameters. The reaction can be followed via the graphics, with the possibility of changing the scale of the graphs at any time. Reactors can be easily placed and removed. Handling the reaction mixtures before and after the reaction is quite simple."

University Joseph Fourier - France

"Currently Teva is using H.E.L CAT 7 hydrogenation system. It was effectively used for screening of hydrogenation catalysts and determination of optimal hydrogenation conditions. Our experience with CAT 7 system showed that it can significantly reduce the time needed for a selection of hydrogenation conditions, mostly by rapid identification of the most relevant screening hits for the further research and development process. In conclusion, H.E.L CAT 7 was found to be very useful choice for our R&D."

Teva Czech Industries - Teva Czech Industries

"We were looking for a high pressure-high temperature reactor system with real time monitoring system to in-situ study our reactions. H.E.L came up with a system that suited our needs and budget. The reactor came with a software that records all the data during the process and it is easy to use. During installation we had a three-day course on the basics of the equipment and the software. “We got the service we asked for."

University of Szeged - University of Szeged

"H.E.L’s PolyBLOCK is a classic invention that allows process development at the fastest rate. We have developed a process for 9 steps carbohydrate project in just 45 days with the help of PolyBLOCK."

Dr Nikhil Jadhav - Aarti Industries

We at TUV Rheinland consider ourselves to be quite fortunate in finding a vendor like H.E.L as the supplier of our Adiabatic Battery Testing Calorimeter. Not only does HEL provide a dynamic, but also a flexible team to work with. H.E.L’s expertise and experience in calorimetry has proven to be one of their strongest assets. The joint partnership with H.E.L has enabled us to develop services from which our company and our customers have benefited. We feel this BTC system has been a key factor to the success of our laboratory.

Japan - TUV Rheinland Battery Laboratory