Bioprocess Development

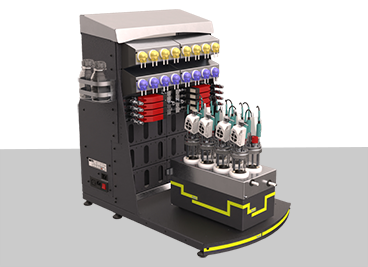

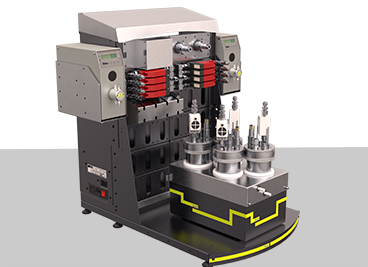

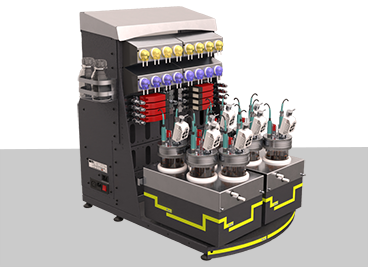

Elevate your bioprocessing capabilities with H.E.L Group’s adaptable and innovative BioXplorer range. The modular design increases flexibility and enables tailored solutions for diverse bioprocesses. Choose from an array of customizable configurations with seamless integration of third-party equipment.

From applications ranging from aerobic fermentation to high-pressure syngas fermentation, the BioXplorer product range delivers optimized solutions. Parallel reactor setups allow for efficient screening, harnessing robust control features to manipulate reactors, capture analytics, and fine-tune parameters.

Reduce costs, streamline operations, and reduce error risks while obtaining ‘real bioreactor’ insights. With H.E.L Group’s expertise, collaborative spirit, robust support, and exceptional service, our BioXplorer range can reshape your bioprocessing journey.