As chemists, process development teams, and R&D groups plan their 2026 priorities, one concern continues to rise to the top: ensuring long-term reliability of catalyst screening systems. High-throughput experimentation has become an essential part of modern catalyst development. Still, many laboratories are realising that the instrument’s reliability is just as crucial as the reliability of the data it generates.

Across the industry, a growing number of legacy catalyst screening platforms are ageing out of support. Some systems are no longer being manufactured, spare parts are increasingly difficult to obtain, and service engineers trained on older models are becoming scarce. For labs running time-critical experiments, this lack of support introduces real risks, equipment downtime, delayed projects, interrupted workflows and rising maintenance costs.

Why Instrument Support Has Become a Strategic Priority

Catalyst development is advancing at an unprecedented rate. New materials, more ambitious pressure and temperature profiles, and an accelerated push toward sustainable processes all place higher demands on screening platforms. In this environment, unsupported equipment can quickly become a bottleneck.

This is why many organisations are shifting toward fully supported, actively manufactured systems that offer the performance they need today and the operational security they’ll need tomorrow

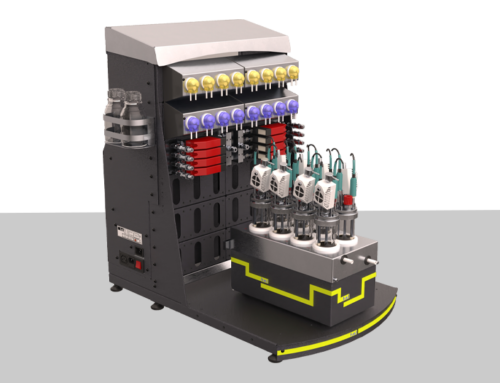

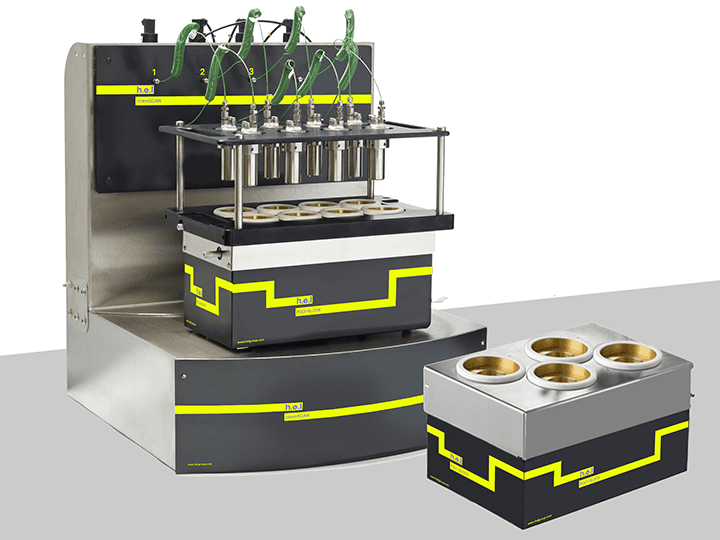

Modern platforms such as ChemSCAN have gained attention for precisely this reason. ChemSCAN provides high-throughput catalyst screening capabilities, backed by a global company with over 40 years of experience and a worldwide service and support network. For labs evaluating long-term reliability, this combination of performance and support offers significant peace of mind.

The Benefits of Choosing a Supported Catalyst Screening System

Selecting a system backed by active manufacturing and global service availability offers several long-term advantages:

- Reduced downtime – quick access to spare parts and trained engineers keeps experiments running.

- Lifecycle confidence – supported instruments are designed with future updates and serviceability in mind.

- Consistent, reliable data – well-maintained systems perform more predictably over years of use.

- Lower total cost of ownership – proactive servicing prevents expensive, unplanned failures.

- Scalability and modernisation – support teams can help integrate upgrades, new accessories, or workflow improvements.

Planning for the Future of Your Catalyst Screening Workflow

Whether motivated by ageing systems, uncertainty around parts availability, or the desire to modernise workflows, many labs are now reviewing their catalyst screening capabilities, ready for 2026. Switching to a supported platform doesn’t just protect against downtime; it can enhance throughput, improve automation, and create more resilient experimentation pipelines.

If reliability, serviceability, and long-term continuity are on your agenda for the new year, exploring fully supported screening solutions such as ChemSCAN is a practical step toward future-proofing your laboratory operations.