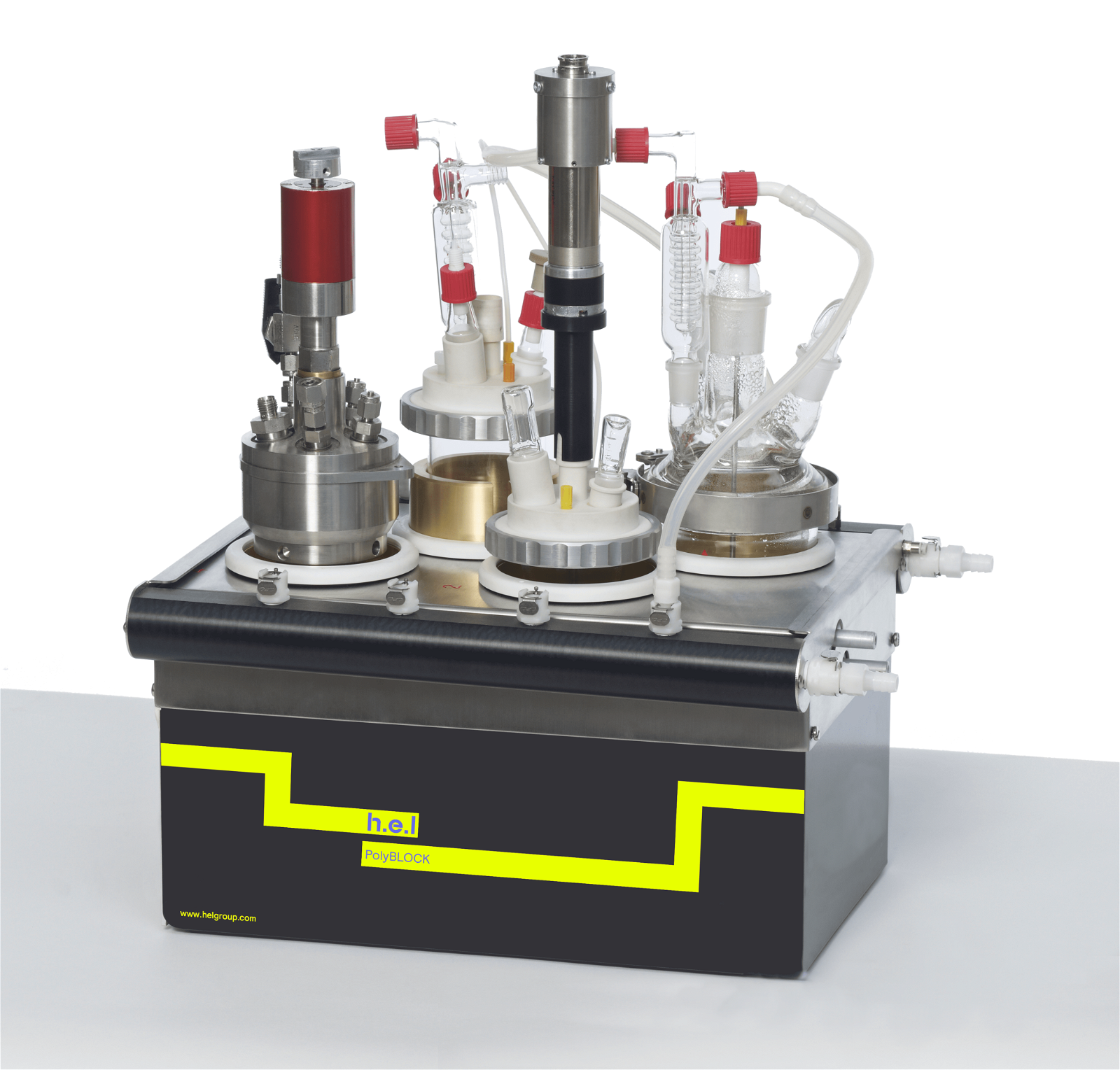

PolyBLOCK | Compact Automated Parallel Synthesis Platform

Key Features

- 4 or 8 Independent reaction zones

- Independent temperature control (100 °C difference between zones, temperature range of -40 °C to +200 °C)

- Independent agitation control (250 to 1500 rpm, suspended mechanical or overhead stirring available)

- Small footprint – no larger than a typical laboratory notebook

- Use any combination of reaction vessels on one platform

- Intuitive control software with a choice of interfaces

Designed to maximize your laboratory’s productivity, parallel synthesis technologies with PolyBLOCK is an easy-to-use, flexible, and compact multi-reactor system.

With either four (PolyBLOCK 4) or eight (PolyBLOCK 8) independently controlled and monitored zones, PolyBLOCK 4 offers working volumes of up to 500 ml and PolyBLOCK 8 up to 120 ml. Reactor options range from 1 ml HPLC vials to round or flat-bottom flasks up to 250 ml and custom reaction vessels up to 500 ml.

Agitation in each zone is independently controlled and temperature monitoring and control is offered with either reactor and/or zone temperature.

Ambient Pressure PolyBLOCK & AutoMATE Brochure

Technical Literature

The following is a list of supporting Technical Literature.

Characterization of the maximum heating performance for the multi-reactor PolyBLOCK 8

Characterization of the cooling performance for the multi-reactor PolyBLOCK 8

Characterization of the heating performance for the multi-reactor PolyBLOCK 8

Characterization of the maximum heating capabilities of the multi-reactor PolyBLOCK 4

Characterization of the heating capability for the multi-reactor PolyBLOCK 4

Publications

The following are a list of some technical publications which highlight the use of the equipment.

Palladium-catalyzed synthesis of carboxylic acid anhydrides from alkenes

Ashok Ramakrishnan, Stefan G. Romeijn and Elisabeth Bouwman

30-Oct-2023

https://www.sciencedirect.com/science/article/pii/S0021951723004372?ref=pdf_download&fr=RR-2&rr=90a28f0ae8b30753(Subscription or purchase maybe required for full access)

Structural analysis of metastable pharmaceutical loratadine form II, by 3D electron diffraction and DFT+D energy minimisation

Grahame R. Woollam, *a Partha P. Das, *b Enrico Mugnaioli, c Iryna Andrusenko, c Athanassios S. Galanis,b Jacco van de Streek, d Stavros Nicolopoulos,b Mauro Gemmi c and Trixie Wagnere

01-Oct-2020

https://doi.org/10.1039/D0CE01216E(Subscription or purchase maybe required for full access)

Rapid synthesis of sodium-rich Prussian white for Sodium-ion battery via a bottom-up approach

Yuming Xi Yangcheng Lu

01-Aug-2020

https://doi.org/10.1016/j.cej.2020.126688(Subscription or purchase maybe required for full access)

Tailoring morphology and bulk density of magnesium ethoxide particles by adding n-hexane and silicone oil

Zhou Lan, Yangcheng Lu

01-Apr-2020

https://doi.org/10.1016/j.partic.2020.02.002(Subscription or purchase maybe required for full access)

Enantioselective Synthesis of a γ-Secretase Modulator via Vinylogous Dynamic Kinetic Resolution

Neil A. Strotman,* Antonio Ramirez, Eric M. Simmons, Omid Soltani, Andrew T. Parsons, Yu Fan, James R. Sawyer, Thorsten Rosner, Jacob M. Janey, Kristy Tran, Jun Li, Thomas E. La Cruz,Charles Pathirana, Alicia T. Ng, and Joerg Deerberg

13-Aug-2018

https://doi.org/10.1021/acs.joc.8b01734(Subscription or purchase maybe required for full access)

Formation mechanism of aroma compounds in a glutathione-glucose reaction with fat or oxidized fat

J. Zhao, T. Wang, J. Xie, Q. Xiao, J. Cheng, F. Chen, S. Wang and B. Sun,

01-Jul-2018

https://doi.org/10.1016/j.foodchem.2018.07.106(Subscription or purchase maybe required for full access)

Influence of Process Parameters on the Heterogeneous Nucleation of Active Pharmaceutical Ingredients onto Excipients

R. Arribas Bueno, C. Crowley, B. Hodnett, S. Hudson and P. Davern, Org. Process. Res. Dev., 2017, 21, 559-570.

01-Mar-2017

https://doi.org/10.1021/acs.oprd.6b00425(Subscription or purchase maybe required for full access)

Synthesis, characterization and performance of bifunctional catalysts for the synthesis of menthol from citronellal

J. Dam, A. Ramanathan, K. Djanashvili, F. Kapteijn and U. Hanefeld, RSC Adv., 2017, 7, 12041-12053.

20-Feb-2017

https://doi.org/10.1039/C6RA25931F(Subscription or purchase maybe required for full access)

One-pot combination of enzyme and Pd nanoparticle catalysis for the synthesis of enantiomerically pure 1,2-amino alcohols

J. Schrittwieser, F. Coccia, S. Kara, B. Grischek, W. Kroutil, N. d'Alessandro and F. Hollmann, Green Chem., 2013, 15, 3318.

01-Sep-2013

https://doi.org/10.1039/C3GC41666F(Subscription or purchase maybe required for full access)

Use of food-grade proteases to recover umami protein–peptide mixtures from rice middlings

Lucia Bagnasco, Valeria M.Pappalardo, Andrea Meregaglia, Thammarat Kaewmanee, Daniela Ubiali, Giovanna Speranzabe. M. Elisabetta Cosulich

01-Jan-2013

https://doi.org/10.1016/j.foodres.2012.11.007(Subscription or purchase maybe required for full access)

Investigation of the Solid-State Polymorphic Transformations of Piracetam

Anthony Maher,*,† Colin C. Seaton,† Sarah Hudson,†,‡ Denise M. Croker,† Åke C. Rasmuson,† and Benjamin K. Hodnett†

05-Nov-2012

https://doi.org/10.1021/cg301418c(Subscription or purchase maybe required for full access)

Effects of Different Organic Acids on Solubility and Metastable Zone Width of Zinc Lactate

Xiangyang Zhang Gang Qian Xinggui Zhou*

27-Sep-2012

https://doi.org/10.1021/je3006453(Subscription or purchase maybe required for full access)

Solid−Liquid Equilibrium of D- and L-Tartaric Acid and Their Importance for Enantioseparation

Xiaofang Wang,† Xiangyang Zhang,† Simon Black,‡ Leping Dang,*,† and Hongyuan Wei†

11-May-2012

https://doi.org/10.1021/je300170y(Subscription or purchase maybe required for full access)

Mixed-level supersaturated design application to a robustness study on an organic synthesis

Alice Croguennoc, Marc Frédéric, Magalie Claeys-Bruno, Roger Phan-Tan-Luu, Michelle Sergent

01-Apr-2012

https://doi.org/10.1016/j.chemolab.2012.01.005(Subscription or purchase maybe required for full access)

Understanding the p-Toluenesulfonamide/Triphenylphosphine Oxide Crystal Chemistry: A New 1:1 Cocrystal and Ternary Phase Diagram

Denise M. Croker,*,†,§ Michael E. Foreman,†,‡ Bridget N. Hogan,†,§ Nuala M. Maguire,†,‡ Curtis J. Elcoate,†,‡ Benjamin K. Hodnett,†,§ Anita R. Maguire,†,∥ Åke C. Rasmuson,†,§ and Simon E. Lawrence†,‡

15-Dec-2011

https://doi.org/10.1021/cg201300e(Subscription or purchase maybe required for full access)

Nucleation kinetics of paracetamol–ethanol solutions from metastable zone widths

Niall A.Mitchell, Patrick J.Frawley

01-Jun-2010

https://doi.org/10.1016/j.jcrysgro.2010.05.043(Subscription or purchase maybe required for full access)

Downloads

The following are a list of available downloads.

My experience with H.E.L dates since 2005. During these years H.E.L was the provider of the most important lab equipment with the help of which I developed many different API pharmaceutical processes in the companies l worked for including Merck, Pfizer, and Theravance. The versatility of the automated lab reactors (AutoLAB), the ease of use of and the accuracy of the TSu and Simular systems, as well as the flexibility of the PolyBLOCK made my work much easier and accurate. I would like to mention the great relationship I established with the service engineers and the sales people at H.E.L. With their help I was able to customize the software and the hardware of the equipment to our specific needs. This readiness to accommodate each customer’s specific needs gives H.E.L the edge over their competitors and makes them the preferred vendor for pharmaceutical lab equipment.

With the polyblock 4 system significant time savings have been achieved compared to using conventional laboratory reactors while at the same time obtaining more information on the process studied. The system has given reproducible process control making it very useful in DOE experiments on a precise recrystallisation where variations due to operational error had to be minimised. Also with the flexibility in reactor size the process was run on smaller scale than previously reducing the demand for a valuable process intermediate.

A versatile time saving tool for QBD & DOE study for all kind of chemistry, crystallization, & even integrated with Calorimetric study. H.E.L motto “Better Chemistry – Faster” matches with output of instrument giving better control over chemistry & faster result. Thanks for making our work simple.

We purchased a PolyBLOCK 4 zone system in November and the system was delivered on time and to our specification. The PolyBLOCK has increased throughput by allowing us to easily and efficiently run multiple reactions. Our system has proven to be very reliable and we utilize it on a daily basis. We are very satisfied with our purchase of the PolyBLOCK 4 and the advice and technical support offered by HEL.

PolyBlock PB4 is ideal and best suited for Pharmaceutical application in terms of flexibility, upgradability for various applications like pH monitoring and control, solubility and MSZW for crystallisation , high pressure Hydrogenation , Online Real Time calorimetry, reflux & inerting , PAT tools in future , overhead motor stirring , extended temperature range -80 to 250 ( depends on the chiller being used with the PB4 ).

Dr D.Y. Patil - Institute of Pharmaceutical Sciences – India

The PolyBLOCK 4 is simple to use for all chemists and biochemists in our company. It allows us to carry out more reactions at a time, under very good temperature control. We also operate the PolyBlock overnight under pre-programmed procedures, to save a lot of precious time. We use different sizes of glassware in the same block, which allows us to investigate our chemistry at small scale, and then scale-up using the same equipment and pre-programmed procedure.

BioCompatibles UK Ltd – United Kingdom

My role within the Green Chemistry Centre at the University of York (UK) is as Clean Synthesis Technology Platform Leader. Through this role I am currently supervising work being undertaken studying the application of heterogeneous catalysts and high-pressure gases for the conversion of biomass derivable compounds. As such our group has recently purchased three high-pressure reactors from H.E.L Ltd. To assist in the evaluation of our heterogeneous catalysts it is vital that stirring in the reactor vessel is control effectively and the reactor designs from H.E.L Ltd. achieve this by use of a suspended stirrer-bar system. As a result of our gas addition requirements some modification to the standard reactor designs were necessary, this being an area that H.E.L Ltd. were especially helpful in catering to our needs. From first contact with H.E.L (via Andrew Coleman), through reactor design and finally to reactor delivery H.E.L Ltd have been a pleasure to work. Throughout our interaction H.E.L Ltd. has proven to be knowledgeable, inventive and very efficient in supporting our research needs. I wholeheartedly support H.E.L Ltd. as a reliable, affordable, professional and helpful company for the design and manufacture of high-pressure equipment, and I certainly intend to use them again when such services are required.

H.E.L’s PolyBLOCK is a classic invention that allows process development at the fastest rate. We have developed a process for 9 steps carbohydrate project in just 45 days with the help of PolyBLOCK.

Dr Nikhil Jadhav - Aarti Industries

Industries and Applications

Pharma, Fine Chemicals, Food/Cooling Crystallization

Control cooling profiles to optimise nucleation and growth, achieving desired crystal size and purity.

Production of liquid medication into tablet form

Research into solubility of liquids to determine the temperature range over which suitable tablets can…

Separation of chemicals

Crystallization of selected chemicals in order to separate them (by filtration) from other more soluble…

Seeded Crystallization

Use seed crystals to control growth kinetics and reduce batch variability for consistent product quality.