Electric vehicles (EVs) have become common on our roads, powered by batteries instead of non-renewable fossil fuels, increasing the demand for safer, more efficient, and longer-lasting batteries. So far, we have discussed how adiabatic calorimetry is crucial in designing safer batteries This blog post will reveal how isothermal calorimetry is a powerful technology used to design higher-performing batteries.

A battery’s performance is closely linked to its heat generation and operating temperature. Thermal modelling is key in analyzing how batteries perform and degrade over time by studying their heat production. Batteries are always thermally active, whether they are charging, discharging, or resting. Isothermal calorimetry is a technique that monitors the heat generated or absorbed during electrochemical processes, providing real-time information on this thermal behavior. In this article, we will explore how EV battery development and validation engineers can leverage this technology to create higher-performing batteries with improved longevity through:

- Data-Driven Insights: Revealing how specific operating temperatures and charge/discharge conditions affect cell capacity and heat generation.

- Preventative Strategies: Quantifying the effects of use and environmental temperatures on cell heat generation. Avoiding suboptimal conditions and ensuring performance and safety.

- Optimized Thermal Management: Optimizing battery management systems using the data insights from cell heat-release profiles.

Applications of isothermal calorimetry in EV battery development

The battery market is currently dominated by lithium-ion batteries (LIBs); however, novel battery chemistries are emerging (e.g., Na-ion batteries, sulphur batteries, solid-state batteries), and even within LIBs, there are differences. Isothermal calorimetry, a non-abusive and non-destructive technique, provides fundamental information to quantify accurately:

- Endothermic and exothermic events, expressed in power (W) and energy (kJ)

- Heat release/uptake profiles during charge/discharge

- Thermal hotspots across cells and modules

- Changes in thermal behavior over repeated cycles (aging and degradation)

An in-depth characterization of the thermal behavior allows engineers to:

- Compare chemistries like NMC, LFP, and solid-state batteries based on quantified energy release/uptake profiles

- Select materials and cell designs with lower heat generation for improved energy efficiency and safety

- Optimize component choices, such as electrolyte formulations and separators, to minimize thermal losses

- Investigate how temperature and C-rate affect heat generation and battery capacity, identifying safe operating windows

- Perform aging studies to track how heat output evolves over successive cycles and over time

- Capture the fine structure in thermal profiles to reveal underlying physical or chemical events (e.g., SEI growth, phase changes)

Thermal management system design

Designing an efficient thermal management system is critical to achieve battery longevity and safety. Isothermal calorimetry provides precise measurements of the heat released during the battery operational cycles, including charge, discharge, and rest cycles. This information helps:

- Predict thermal loads during real-time operational conditions

- Improve TMS design for different climates and driving cycles

- Avoid situations where overheating (leading to thermal runaways) or underheating (increasing the internal resistance) can occur.

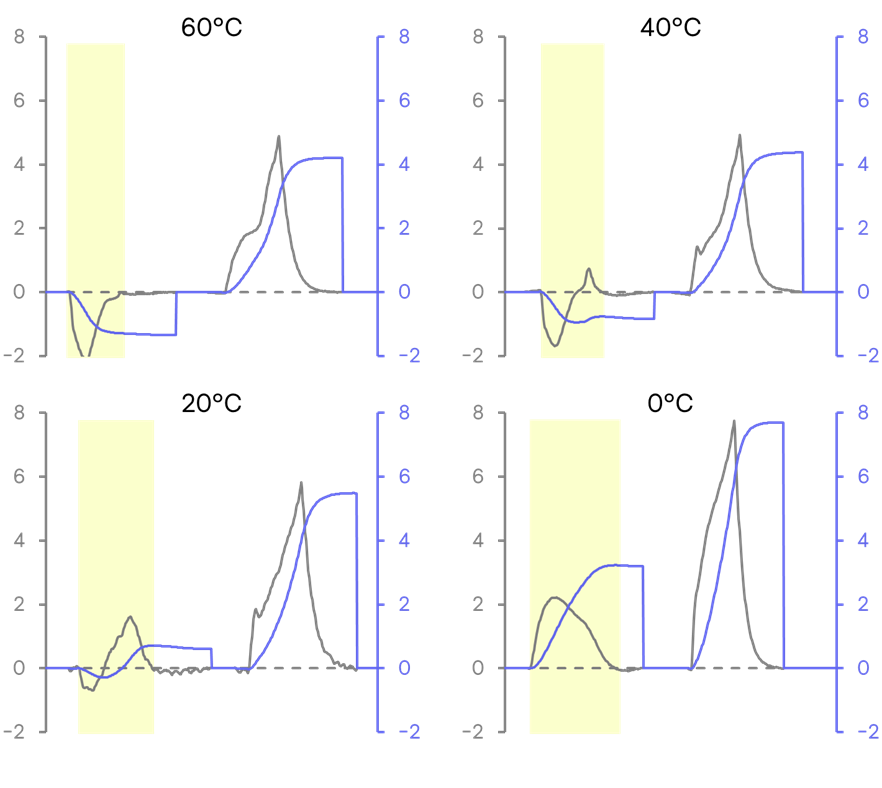

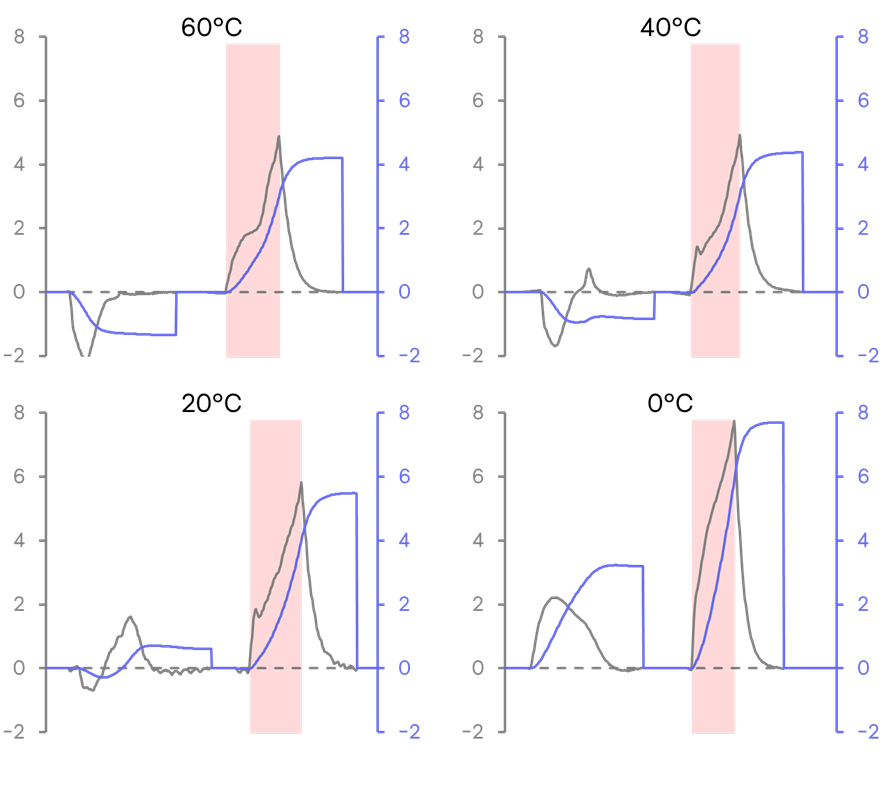

Thermal behavior during charge (yellow) and discharge (red) of a battery at different temperatures. In grey, heat released in W, and in blue, energy released in kJ.

Temperature extremes amplify these concerns. At low temperatures, batteries produce more heat due to higher resistance. At high temperatures, chemical reactions accelerate, sometimes dangerously so. Calorimetry helps balance these risks by measuring various operational states, including normal usage, high-stress scenarios, and extended cycling.

Optimization of operation conditions

Understanding how temperature, state of charge (SOC), and charge/discharge rates (C-rates) affect heat output is key to maximizing performance. Batteries often generate more heat at higher SOCs, due to increased internal resistance and the effect of potential side reactions. Higher C-charges (fast charging and/or discharging) yield faster heat accumulation. Low temperatures combined with moderate loads can lead to heat spikes and reduced efficiency.

Traditional temperature measurement methodologies, such as using thermocouples or infrared (IR) sensors in environmental chambers, can track surface or ambient temperature. While this information is useful, it does not reveal how and when heat is being generated inside the cell. These techniques also fall short in maintaining precise environmental control and accurate temperature measurement, especially under high-load or dynamic cycling conditions, hindering their use for in-depth thermal analysis.

Conversely, isothermal calorimetry provides real-time measurement of heat generation, offering insights into the thermal behavior under a wide range of conditions. Understanding how the battery behaves at different temperatures can help design a safer BMS and inform safe operating windows for extended battery life.

Cell balancing and pack design

An EV battery pack is a complex assembly of individual cells organized in a way that allows them to efficiently store and release energy when needed, resulting in increased capacities. However, each of the individual cells releases energy during the operation, which can lead to inconsistency between cells. Uneven heat generation can lead to hotspot formation, accelerated degradation of individual cells, and reduced pack performance and safety. The early identification of these discrepancies can help engineers improve cell balancing strategies and pack layout to promote thermal uniformity, enhancing reliability and lifespan.

Aging and degradation

As batteries age, their internal chemistry changes, affecting their heat profile. Isothermal calorimetry can help manufacturers track how heat generation evolves during the battery lifetime. This, in turn, can help with the design of predictive maintenance algorithms, accurate lifetime estimation, and warranty modelling.

It also provides valuable input for second-life or recycling programs by identifying thermally stable cells when capacities drop to 80% – 60% after extensive use.

Why EV Manufacturers Should Invest in Isothermal Calorimetry

As we can see, batteries can behave in different ways depending on various conditions. Integrating isothermal calorimetry into battery development fills critical data gaps, empowering engineers to design tailored battery components and management strategies that meet the increasing performance demands of current and next-gen EVs.