Flow Chemistry is changing the way chemical synthesis is carried out in research labs and large-scale manufacturing. The move away from traditional batch processing to continuous flow methods (like H.E.L’s FlowCAT) brings better control, increased safety, and faster optimization of reaction conditions. With ongoing advances in reactor design and automation, Flow Chemistry is expanding its impact across industries, from pharmaceuticals to sustainable manufacturing.

In this article, we will discuss how Flow Chemistry compares to traditional approaches, explore its current applications, and highlight some key trends driving innovation in the field.

Introduction: What Is Flow Chemistry?

Traditional batch processing involves filling a reactor with reactants, waiting for the reaction to complete, then emptying, cleaning, and repeating the cycle. It works but is often time-consuming, hard to scale, and carries safety risks, especially for hazardous or exothermic reactions. There is also unavoidable downtime between runs, which limits productivity.

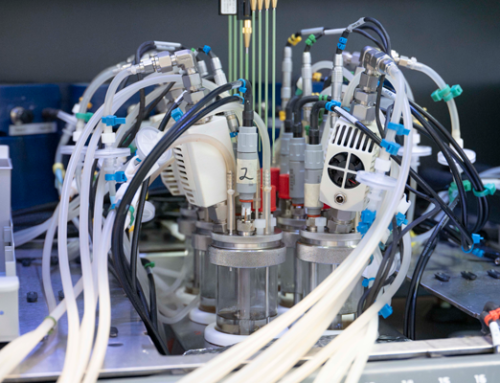

Flow Chemistry offers a more efficient alternative. Instead of stopping and starting, reactants are continuously pumped through a reactor, mixing and reacting in real time. The product exits the system at the other end. This approach allows precise control over reaction parameters like temperature, pressure, and residence time, making processes safer, faster, and more scalable.

Applications of Flow Chemistry

The appeal of Flow Chemistry lies in its versatility. Its use is growing in a number of sectors, thanks to its ability to speed up reactions, improve safety, and reduce waste.

Pharmaceuticals and Personalized Medicine

Flow Chemistry is helping pharmaceutical companies streamline the production of active pharmaceutical ingredients (APIs). Continuous flow systems are especially valuable for personalized medicine, where small batches must be produced quickly and consistently. Automated platforms also reduce human error and increase reproducibility, key factors in high-precision environments where consistent batch quality is required.

High-Throughput Screening

In research and development, Flow Chemistry enables rapid screening of multiple reaction conditions. Combined with automation, it accelerates the optimization process, helping chemists quickly identify the best parameters for a given reaction.

Green Chemistry

Flow systems align well with green chemistry principles. Smaller volumes and better heat and mass transfer reduce solvent use and waste generation. Operating at steady state also improves energy efficiency.

Some of the environmental benefits include:

- Lower solvent consumption

- Reduced energy use due to improved thermal control

- Minimal by-products and waste

- Safer handling of hazardous reagents

Thanks to continuous operation, small internal volumes, and a better surface area to volume ratio, flow reactors reduce the risk of thermal runaway, making them a safer option for challenging chemistries.

Market Drivers

Several trends are accelerating the adoption of Flow Chemistry:

- Stricter regulations: Governments and agencies are developing legislation to make manufacturing processes safer, cleaner, and more controlled.

- Sustainability goals: Industries are under pressure to reduce emissions, decrease the use of toxic substances (e.g. solvents), and improve process efficiency.

- Demand for complex synthesis: The need for tailored APIs, polymers, and specialty chemicals is growing.

- Support for continuous manufacturing: Regulatory bodies are beginning to recognize continuous production methods as compliant with GMP standards, further encouraging their use in pharmaceutical manufacturing.

As a result, the global Flow Chemistry market is expected to grow at a compound annual growth rate (CAGR) of over 12%, reaching an estimated $3.5 billion by 2032.

Emerging Trends in Flow Chemistry

Flow Chemistry is evolving rapidly to become more and more attractive in a changing landscape. with innovations in reactor design, process integration, and digitalization. Some of the emerging trends include:

- Miniaturization and Modular Microreactor Platforms

Modern systems use compact, modular microreactors with lateral dimensions below 1 mm. These systems have a high surface-area-to-volume ratio, which improves heat transfer and reaction efficiency. Modular design makes reconfiguring setups for different reactions easier, reducing both cost and complexity.

- Multi-Step Flow Synthesis

Recent developments have resulted in configurations allowing multiple reaction steps within a single flow system. This includes multicomponent reactions where reagents are added sequentially based on their reaction pathways. It streamlines workflows and enhances selectivity.

- Automation and Optimization

Automation in Flow Chemistry reduces human error, increases reproducibility, and accelerates reaction optimization. Adding automated pumps and integrated control software (like H.E.L’s FlowCAT and WinISO) allows for real-time adjustments of flow rates, temperature, and pressure, leading to better yields and consistent product quality.

- Integration with PAT and AI

The integration of Process Analytical Technology (PAT) allows in-line sensors (e.g., UV-VIS, IR, NIR) to monitor reactions in real-time. This enables closed-loop feedback to adjust process conditions automatically to optimize the reaction.

Recent developments include AI-powered process optimization, where machine learning models use data from early runs to predict reaction behavior and optimize parameters without human input.

- Novel Reactor Designs

Innovations like photochemistry, electrochemistry, gas-phase flow, and packed-bed heterogeneous catalysis are expanding the reactions suitable for flow chemistry.

Additionally, 3D-printed reactors are making novel reactor geometries more readily available. While current materials (e.g., polypropylene) have some chemical compatibility limitations, the ability to quickly design and test new reactor formats is accelerating innovation.

Conclusion

Flow Chemistry continues to gain momentum as a powerful alternative to batch processing, offering better control, enhanced safety, and easier optimization. Recent breakthroughs, such as microreactor platforms and AI-powered process control, are pushing the boundaries of what is possible in continuous chemical manufacturing.

Flow Chemistry is becoming the standard for modern chemical synthesis with its scalability, compatibility with green chemistry initiatives, and alignment with industry regulations.

As industries continue to push for efficiency, safety, and sustainability, Flow Chemistry stands at the forefront, delivering optimized solutions that meet regulatory and environmental expectations.