In recent months, shortages of sterile plastic “growbags” have threatened the global vaccine rollout, with manufacturers allegedly coming close to stopping production over the scarcity of sterile liners. But is there another way? Are we too reliant on single-use technologies?

- The bottleneck that threatened the rollout of Covid-19 vaccines

- What is the human and financial cost in the fight to vaccinate the world?

- The colossal challenge to vaccinate the rest of the world

The bottleneck that threatened the rollout of Covid-19 vaccines

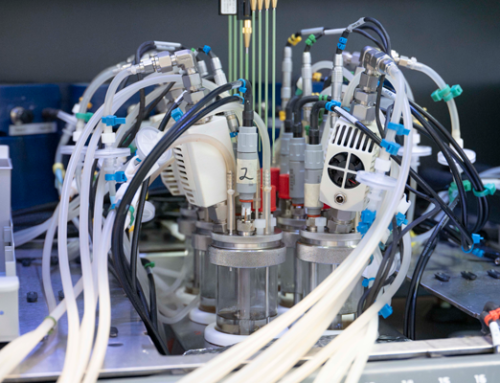

Covid-19 inoculations are developed in giant plastic bags used as liners for bioreactors that grow vaccine cells. Back in February, vaccine manufacturers such as BioNTech/Pfizer, Moderna, and Novavax were struggling to get supply of these bags, thereby producing a bottleneck that threatened the rollout of Covid-19 vaccines around the world.

One of the larger global suppliers of these bags is MilliporeSigma, a division of Germany’s Merck, which has seen an “unprecedented demand”1 for Covid-19 related products. At the same time, Thermo Fisher aimed to increase production by 50 percent last year and anticipated expanding it by another 50 percent in 20212.

To avert a prolonged crisis, vaccine manufacturers were encouraged not to hoard supplies of the bags, but is there another way?

What is the human and financial cost in the fight to vaccinate the world?

If vaccines could have been made faster without delays at the beginning of 2021, would the position we are currently in be different?

Understandably, vaccines have never been manufactured on such a large scale, but were all options explored, or was single-use the go-to technology by default? Perhaps limited due diligence was done in the strategic procurement of bioreactors, and alternative technologies, such as glass and steel reactors coupled with autoclaves for sterilization, were not investigated? This approach may have led to less risk and disruption and more resilience in the diversity of the supply chain.

Though these methods are much more sustainable, changing manufacturing and research methods would have caused a delay to shipments as regulatory authorities must approve such changes. Having said that, perhaps similar fast-track procedures for the global emergency could have been allowed as this was the case for fast-track clinical trials.

The colossal challenge to vaccinate the rest of the world

Looking ahead, the Western world approaches completion of its initial domestic vaccination programs, with preparations for the winter and/or variant booster jabs.

However, we still face the colossal challenge of vaccinating the rest of the estimated 8 billion global population. This should not be underestimated. If alternatives are not considered and lessons learned, similar challenges with single-use plastics may arise in the future.

Undoubtedly, the best solution should always be used, but in hindsight, it might be worth factoring in and normalizing alternative research and manufacturing methods. Methods that might just offer a ready-made contingency plan and help reduce the global dependence on throw-away plastics and make a partial or full switch to reusable and autoclavable glass and steel bioreactors.

References

- https://www.ft.com/content/b2f4f9cf-af80-428f-a198-2698ceb4c701

- https://www.beckershospitalreview.com/supply-chain/shortage-of-plastic-growbags-threatens-global-vaccine-supply.html