Catalyst Screening Platforms | Manual Systems

Our complete range of multi-sample high throughput catalyst screening vessels has been designed to provide a simple easy-to-use tool for high-pressure reaction screening. They can be used directly with stirring hotplates or oil baths.

CAT 7, 18, and 24: The CAT 7, 18, and 24 are manual catalyst screening reactors, supporting 7, 18, and 24 vials, respectively.

DigiCAT 96: The DigiCAT 96 is an automated catalyst screening platform that supports a standard 96-well Zinsser block for high throughput screening early on in catalyst development.

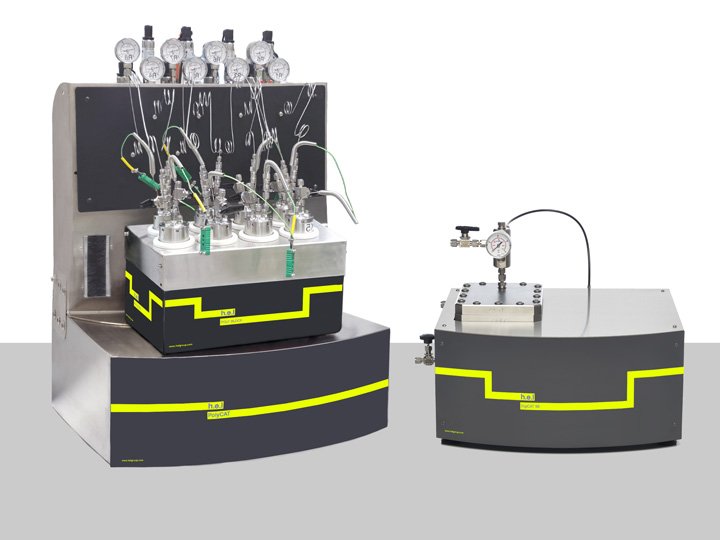

PolyCAT 4 and PolyCAT 8: The PolyCAT 4 and 8 are bench-top, automated parallel catalyst screening platform, designed for the rapid screening of high-pressure reactions and catalysts.

CAT 7, CAT 18 & CAT 24

CAT Reactors:

7, 18 or 24 Vial, Manual Catalysis Screening Reactor

The CAT 7, 18, and 24 are manual catalyst screening reactors, supporting 7, 18, and 24 vials, respectively. Each unit is a single vessel into which sample vials are placed, with the CAT 7 supporting 10 ml vials, the CAT 18, 2 ml vials, and the CAT 24 holding 4 ml vials. The sample vials within the CAT reactor blocks are stirred and heated on a hot plate under manual operation. They are held at the same pressure and temperature, enabling replicates to be performed within the same experiment, thereby accelerating development time.

Features and Options:

Vessel Types and Volumes

- CAT 7: Designed to be used with 7 standard 10 ml vials

- CAT 18: Designed to be used with 18 standard 2 ml vials

- CAT 24: This allows the use of 24 open-top vials to be used at high pressure and temperature. The typical test volume is around 1 ml

Temperature

- All samples within each vessel are maintained at the same temperature and pressure, up to 100 bar / 250 °C.

- Reactor block temperature can be monitored directly via a thermocouple probe.

Manual High-Pressure Reactor

- Valves and pressure gauge provided to manually purge (for example, inert) and further pressurize with reacting gas (for example, hydrogenation), up to 100 bar.

Stirring Available

- Magnetic stirring in each reaction vial

Sample Integrity

- To prevent carryover, the vials can be fitted with septa.

- For larger vessels used in the CAT 24, the lids are fitted with cold fingers, which are chilled by an external coolant (eg tap water), to mitigate the crossover of vapors between reaction vessels.

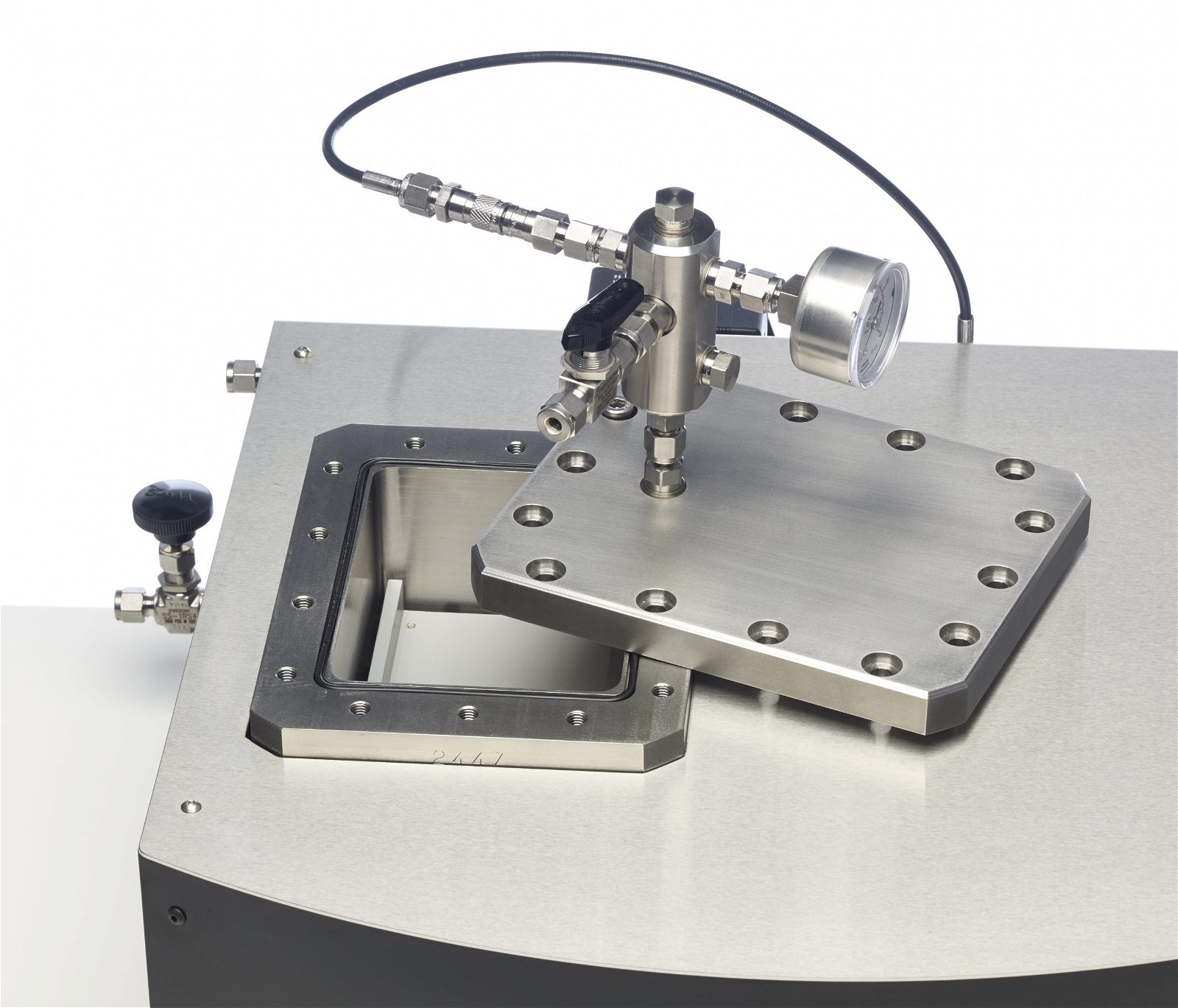

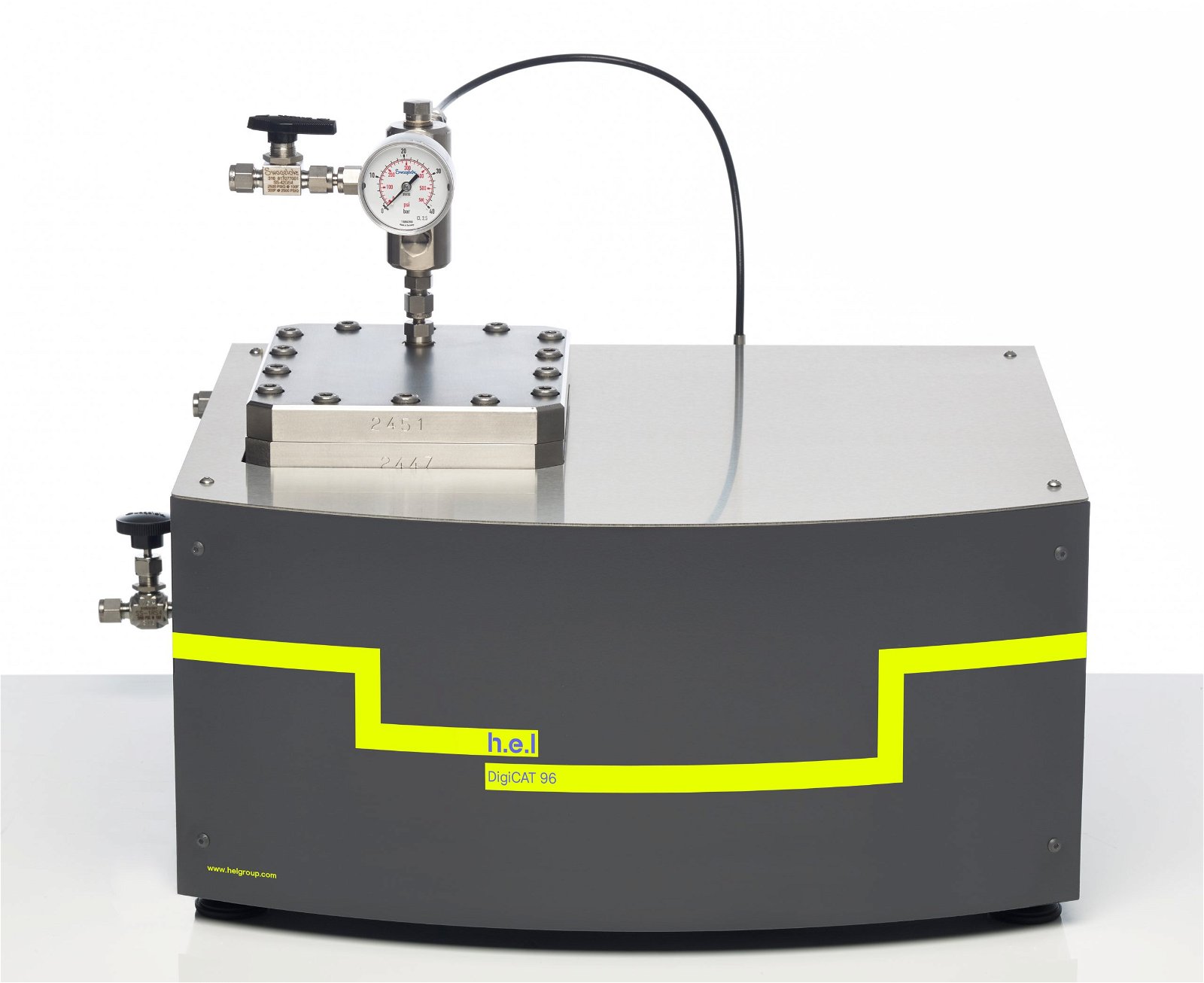

DigiCAT 96

DigiCAT 96:

A 96 Well Plate Automated Catalysis Screening Platform

The DigiCAT 96 is an automated catalyst screening platform that supports a standard 96-well Zinsser block for high throughput screening early on in catalyst development. The system maintains the same temperature and pressure across each sample, enabling the rapid collection of statistically representative data on the performance of a candidate catalyst. The 1 ml vials are also compatible with HPLC, allowing the reaction mixes to be directly analyzed by compatible analytical techniques.

Features and Options:

Vessel Types and Volumes

- 96 well Zinsser block, for 96 simultaneous reactions in 1 ml vials.

Temperature

- All samples are maintained at the same temperature, between ambient and 200 °C.

High-Pressure Reactor

- Automated gas purge (for example, inert) and further pressurize with reacting gas (for example, hydrogenation), up to 100 bar

Stirring Available

- Magnetic stirring for each reaction vial

Intelligent Software Control and Analysis

- Control software enables regular data logging, multi-step recipes, parameter control and feedback loops.

Safety Features

- Include automatic user-configurable shutdown procedures if a safety condition is exceeded to ensure user safety.

- Automatic hardware and software fail-safes are installed on every system

PolyCAT 4

PolyCAT 4:

Bench-top, 4-reactor, automated parallel catalyst screening platform

The PolyCAT 4 is a bench-top, automated parallel catalyst screening platform, designed for the rapid screening of high-pressure reactions and catalysts. The 4 reactor variant, supports reactors ranging from 16ml to 500ml. As with the fully automated ChemSCAN, each stirred reactor is independently controlled and monitored, allowing screening tests to be carried out concurrently and accelerating development time.

Features and Options:

Vessel Types and Volumes

- The system supports four reactors in parallel operation. Reactor volumes range from 16ml to 500ml, available in SS316 Stainless Steel or Hastelloy.

Temperature Control

- Ambient to 250 ⁰C.

- Options to decrease the range down to -40 ⁰C (circulator dependent)

- A separate mantle around each reactor allows the temperature to be controlled individually, with a range/difference of over 100 °C between the reactors.

High Pressure and Vacuum Systems

- Each reactor can be independently pressurized up to 200 bar.

- Pressure gauges, or optional transducers, enable reaction pressure monitoring.

Control Options

- Reactors can be set to different start pressures, allowing the controlled stirring to initiate the reaction.

- Availability of manual purge and gas feed for each reactor.

Stirring Available

- Indirect agitation with magnetic stirrer bar as standard.

- Suspended mechanical agitation for efficient mixing on small-scale and non-viscous samples.

- Optional Overhead direct agitation for larger vessels.

Intelligent Software Control and Analysis

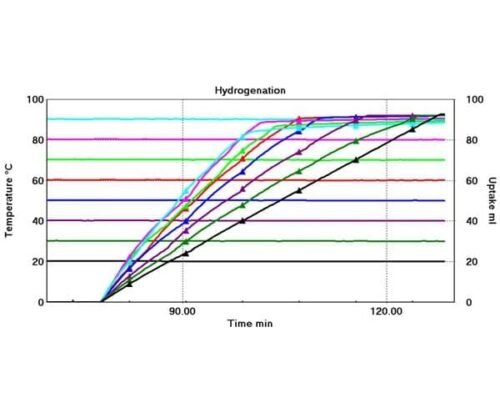

- Control software enables regular data logging, multi-step recipes, parameter control, and feedback loops.

- Experiments can be designed to:

- Run all reactions at the same temperature and pressure -while varying the catalyst or reagents.

- Keep catalyst loads identical but vary the initial pressure.

- Run individual reactors with different loads, pressure, and temperatures

Safety Features

- Include automatic user-configurable reaction detection and shutdown procedures, to ensure user safety.

- Compact manifold for easy manual purge and pressurization.

- Automatic hardware and software fail-safes are installed on every system

PolyCAT 8

PolyCAT 8:

Bench-top, 8-reactor, automated parallel catalyst screening platform

The PolyCAT 8 is a bench-top, automated parallel catalyst screening platform, designed for the rapid screening of high-pressure reactions and catalysts. The 8 reactor variant, supports reactors ranging from 16ml to 500ml. As with the fully automated ChemSCAN, each stirred reactor is independently controlled and monitored, allowing screening tests to be carried out concurrently and accelerating development time.

Features and Options:

Vessel Types and Volumes

- The system supports four reactors in parallel operation. Reactor volumes range from 16ml to 500ml, available in SS316 Stainless Steel or Hastelloy.

Temperature Control

- Ambient to 250 ⁰C.

- Options to decrease the range down to -40 ⁰C (circulator dependent)

- A separate mantle around each reactor allows the temperature to be controlled individually, with a range/difference of over 100 °C between the reactors.

High Pressure and Vacuum Systems

- Each reactor can be independently pressurized up to 200 bar.

- Pressure gauges, or optional transducers, enable reaction pressure monitoring.

Control Options

- Reactors can be set to different start pressures, allowing the controlled stirring to initiate the reaction.

- Availability of manual purge and gas feed for each reactor.

Stirring Available

- Indirect agitation with magnetic stirrer bar as standard.

- Suspended mechanical agitation for efficient mixing on small-scale and non-viscous samples.

- Optional Overhead direct agitation for larger vessels.

Intelligent Software Control and Analysis

- Control software enables regular data logging, multi-step recipes, parameter control, and feedback loops.

- Experiments can be designed to:

- Run all reactions at the same temperature and pressure -while varying the catalyst or reagents.

- Keep catalyst loads identical but vary the initial pressure.

- Run individual reactors with different loads, pressure, and temperatures

Safety Features

- Include automatic user-configurable reaction detection and shutdown procedures, to ensure user safety.

- Compact manifold for easy manual purge and pressurization.

- Automatic hardware and software fail-safes are installed on every system

Publications

The following are a list of some technical publications which highlight the use of the equipment.

PdCu single atom alloys supported on alumina for the selective hydrogenation of furfural

Mohammed J. Islam, Marta Granollers Mesa, Amin Osatiashtiani, Jinesh C. Manayil, Mark A. Isaacs, Martin J. Taylor, Sotirios Tsatsos, Georgios Kyriakou

15-Dec-2021

https://doi.org/10.1016/j.apcatb.2021.120652(Subscription or purchase maybe required for full access)

Production of ethyl lactate by activated carbon-supported Sn and Zn oxide catalysts utilizing lignocellulosic side streams

Riikka Kupila, Katja Lappalainen, Tao Hu, Anne Heponiemi, Davide Bergna, Ulla Lassi

01-Aug-2021

https://doi.org/10.1016/j.apcata.2021.118327(Subscription or purchase maybe required for full access)

Lignin-based activated carbon-supported metal oxide catalysts in lactic acid production from glucose

Riikka Kupila, Katja Lappalainen, Tao Hu, Anne Heponiemi, Davide Bergna, Ulla Lassi

01-Feb-2021

https://doi.org/10.1016/j.apcata.2021.118011(Subscription or purchase maybe required for full access)

The effect of metal precursor on copper phase dispersion and nanoparticle formation for the catalytic transformations of furfural

Mohammed J. Islam, Marta Granollers Mesa, Amin Osatiashtiani, Martin J. Taylor, Jinesh C. Manayil, Christopher M. A. Parlett, Mark A. Isaacs, Georgios Kyriakou

01-Sep-2020

https://doi.org/10.1016/j.apcatb.2020.119062(Subscription or purchase maybe required for full access)

Ruthenium Catalyzed Direct Asymmetric Reductive Amination of Simple Aliphatic Ketones Using Ammonium Iodide and Hydrogen

Dr. Tamal Ghosh, Dr. Martin Ernst, Prof. Dr. A. Stephen K. Hashmi, Dr. Thomas Schaub

01-Jun-2020

https://doi.org/10.1002/ejoc.202000750(Subscription or purchase maybe required for full access)

Quantification of Cavitation Activity by Sonoluminescence To Study the Sonocrystallization Process under Different Ultrasound Parameters

Judy Lee,*,†,∥ Kyuichi Yasui,‡ Muthupandian Ashokkumar,§ and Sandra E. Kentish

01-Jul-2018

https://doi.org/10.1021/acs.cgd.8b00547(Subscription or purchase maybe required for full access)

Platinum-Based Heterogeneous Catalysts for Nitrile Synthesis via Aerobic Oxidative Coupling of Alcohols and Ammonia

Yuliya Preger, Thatcher W. Root and Shannon S. Stahl

01-Jun-2018

https://doi.org/10.1021/acsomega.8b00911(Subscription or purchase maybe required for full access)

Pressurized CO2 as a carboxylating agent for the biocatalytic ortho-carboxylation of resorcinol

Katharina Plasch, Gerhard Hofer, Walter Keller, Sam Hay, Derren J. Heyes, Alexander Dennig, Silvia M. Glueck and Kurt Faber

01-Mar-2018

https://pubs.rsc.org/en/content/articlelanding/2018/gc/c8gc00008e(Subscription or purchase maybe required for full access)

Enantiopure Narrow Bite-Angle P–OP Ligands: Synthesis and Catalytic Performance in Asymmetric Hydroformylations and Hydrogenations

Dr. Héctor Fernández-Pérez,Dr. Jordi Benet-Buchholz,Prof. Dr. Anton Vidal-Ferran

21-Oct-2014

https://doi.org/10.1002/chem.201404731(Subscription or purchase maybe required for full access)

Direct synthesis of formic acid from carbon dioxide by hydrogenation in acidic media

Séverine Moret, Paul J. Dyson & Gábor Laurenczy

01-Jun-2014

https://www.nature.com/articles/ncomms5017?origin=ppub(Subscription or purchase maybe required for full access)

High-throughput screening of monometallic catalysts for aqueous-phase hydrogenation of biomass-derived oxygenates

Jechan Lee, Ye Xu, George W. Huber

01-Mar-2013

https://doi.org/10.1016/j.apcatb.2013.03.031(Subscription or purchase maybe required for full access)

Chiral Rhodium Complexes Derived From Electron-Rich Phosphine-Phosphites as Asymmetric Hydrogenation Catalysts

Wenqin Shen, Geoffrey A. Tompsett, Karl D. Hammond, Rong Xing, Fulya Dogan, Clare P. Grey, W. Curtis Conner, Scott M. Auerbach, George W. Huber

01-Oct-2010

https://doi.org/10.1021/om200933b(Subscription or purchase maybe required for full access)