Stepping into 2025

Take a look back at 2024:

2024 was an exciting year for H.E.L Group, both operationally and research-wise, as we continued to strengthen our position in current markets and geographies, but also expanded into new areas with product launches and appointments. At a macro level, the beginning of the year saw very challenging global market conditions, particularly in the biotech sector. With wide diversification both geographically and at a product and application scale, we have successfully navigated these challenges, expanding global reach and continuing to develop a comprehensive product portfolio in well-established markets, such as process safety and chemical synthesis, where we have been a trusted partner for years.

Expansion of battery calorimetry capabilities

The demand for larger, more efficient batteries has grown exponentially over the last few years, as the automotive industry shift towards electric vehicles (EVs). Current lithium-ion batteries face issues relating to charging times and thermal stability, highlighting a need for novel battery technologies and chemistries.

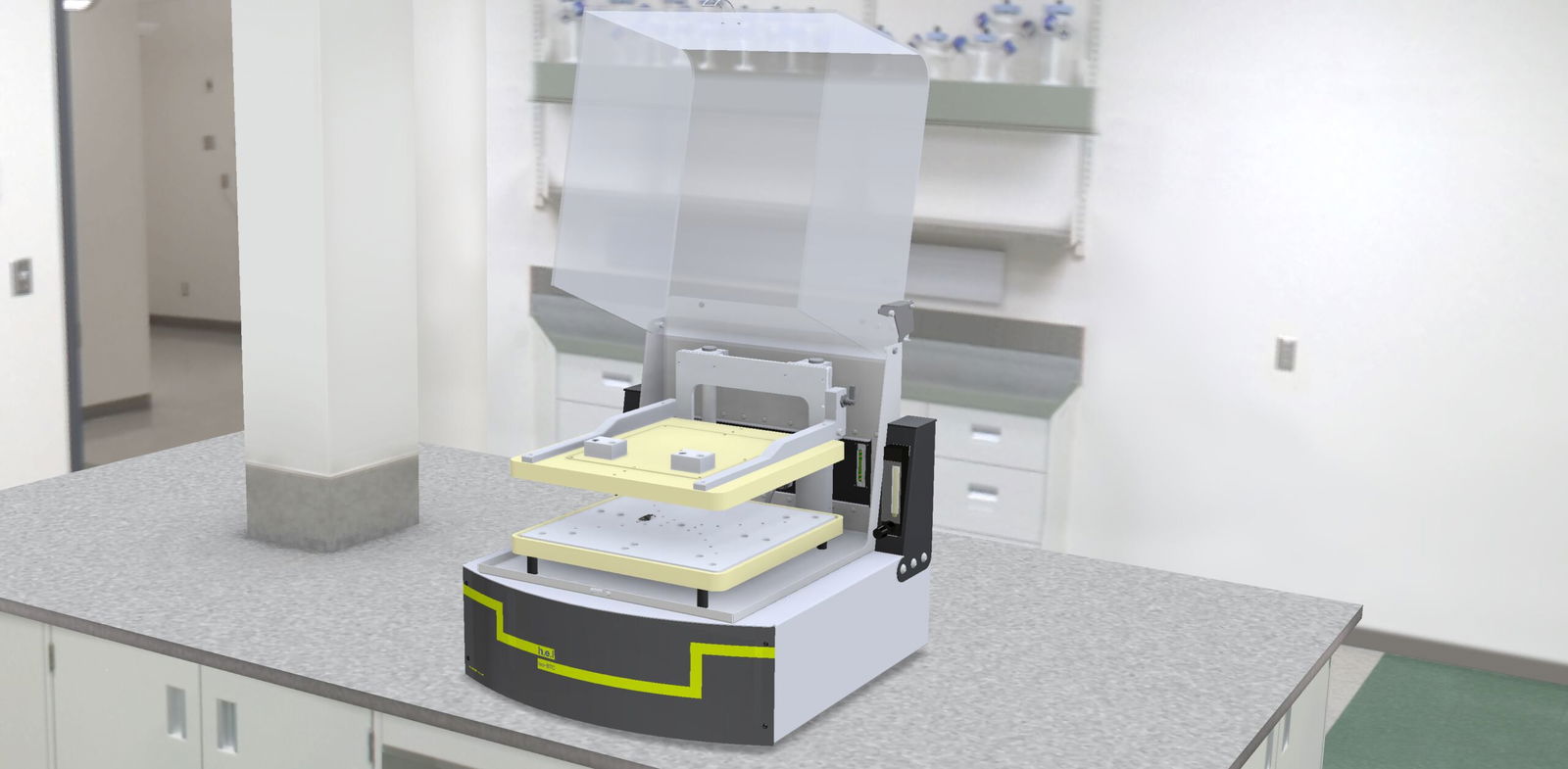

To support advancements in battery research, we introduced the iso-BTC e, designed to ensure the safety and high-performance of semiconductor technologies for use in EVs, data processing, and energy storage. This new specialized isothermal calorimeter provides direct, real-time measurements of heat power in semiconductors, enabling development of effective thermal management strategies.

Additionally, we have seen huge growth in the Indian battery market, where there are ambitious targets of achieving 500GW of non-traditional fuel-based electricity capacity by 2030, and goals to install standalone battery storage systems and integrate renewable projects into the energy infrastructure. Working in collaboration with organizations such as the Automotive Research Association of India and GVS Cibatech, we are advancing research in the region, facilitating the development of larger, more powerful batteries to drive the country’s transition to sustainable energy sources.

To further strengthen our expertise in thermal safety, we appointed Professor Yih-Shing Duh as Chief Scientific Advisor. With over 30 years’ experience in petrochemical research and thermal testing, Professor Duh is supporting the continued development of our battery calorimeter portfolio, conducting demonstrations and delivering industry application training for our sales and after-sales personnel.

Delivering global commercial effectiveness

Internally, 2024 marked the first full year in our new purpose-designed facilities in Hemel Hempstead, which has significantly improved operational efficiency, allowing us to accelerate delivery timelines to our customers and partners. The move has also been reflected in our team’s responses to the bi-annual employee survey, with an all-time high in employee retention. Additionally, we reinforced our commitment to process safety and chemical synthesis—two areas where we have built a strong reputation over the years. We conducted several focused commercial effectiveness initiatives, aimed at identifying market gaps and emerging trends. This work has helped us gain deeper insights into customer needs and industry developments, ensuring our solutions remain innovative and aligned with the demands of these critical fields.

The appointment of our new Product Manager, Rich Waller, in combination with our experienced team of Sales Directors, has driven our success in both the biotechnology and battery sectors, improving connections between production and sales teams and increasing the scope of internal sales training. To further enable our customers’ research in these industries, we also appointed two new specialist distributors, Paralab and ProAnalytics, to provide technical and field application support.

Looking forward to 2025

As we step into 2025, we anticipate major growth in two key market areas: battery testing, where there is increasing demand for more powerful and efficient technologies, and biotechnology, where there has historically been an unmet need for novel tools to support industrial scale testing and manufacturing. Advances in both these industries will support us as in addressing some of the greatest climate challenges we are currently facing.

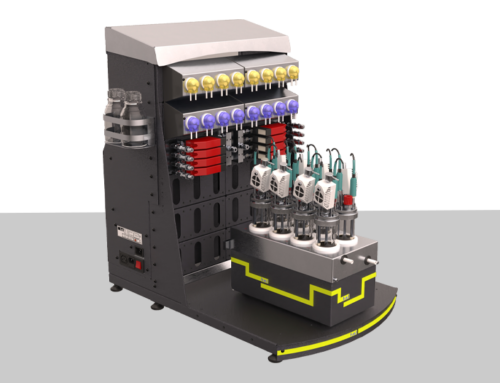

Sustainable materials from pressurised bioreactors

One area of bioprocessing poised for increased investment is the use of pressurized bioproduction for the manufacture of renewable resources. Industrial microbial fermentation has emerged as a promising solution for both climate change and the global energy crisis. High-pressure automated bioreactors, such as our BioXplorer range, optimize biomass fermentation by balancing biological, chemical, and operational requirements of biomass fermentation. This, in turn, is facilitating large scale manufacturing of products such as biofuels, including Sustainable Aviation Fuels (SAF), alternative protein sources, and biomass fermentation. The implementation of advanced automation also helps to improve volumetric productivity and molar yield, making pressurized reactors ideal for gas fermentation and broader manufacturing applications. We are already working with several partners in the space, combining BioXplorers with mass spectrometers, to deliver rapid fermentation with inline analytical capabilities on a benchtop scale.

Growth in the battery market

The Indian government has committed to cut their emissions to net zero by 2070, and 2025 will be a critical year in this mission as the country transitions to cleaner energy sources. We will continue to provide innovative tools for the battery testing market, supporting research into higher battery storage, thermal characteristics, and development of new chemistries. Our aim is to meet the industry’s needs including eVehicles, following our mission statement of creating a “Healthier, Safer, and More Sustainable for Everyone”.

More and more mainstream vehicle manufacturers are investing into battery research, with Honda unveiling its plans for small solid-state batteries in November 2024, and Toyota approaching widespread adoption of its solid-state technology. To support this focus on novel battery technologies, we will continue to optimize our calorimeters for the semiconductor market; semiconductor technologies are increasingly integrated into battery systems, enabling the design of innovative batteries with smart sensor and thermal management systems.

What the future looks like

We are beginning to see a shift in service and instrumentation providers, with sales and technical teams following an application-based approach, working directly with customers and partners to identify the right instrumentation for their research. In doing so, we will deliver bespoke, innovative solutions to a wide range of challenges, working in collaboration with partners to increase productivity and efficacy.

For the wider scientific community, we will continue to add to our knowledge hub, providing educational content across the chemical synthesis, process safety, sustainable energy, biotechnology, and battery industries, delivering webinars and seminars alongside live demos of our instruments to share best practices. Through these platforms, we will open up new opportunities for innovation, demonstrating applications of instruments and the possibilities for automation through our powerful software capabilities.

Thank you to the team at H.E.L for your hard work, and to our partners for your ongoing support; we look forward to working together to unleash the full potential of the scientific community.