What is Hydrogenation and Why it Matters ?

Hydrogenation is a chemical process where hydrogen molecules (H₂) are added to a compound, usually in the presence of a catalyst, to produce a saturated compound.

Hydrogenation is widely used in pharmaceutical, agrochemical, and specialty chemical industries to reduce double bonds and functionalize molecules. Whether you’re developing new catalysts or scaling up reactions, controlling gas-liquid interactions under pressure is essential for reproducibility, safety, and speed.

Hydrogenation requires high pressures to be maintained in the reaction vessel and also tends to be a highly exothermic reaction, resulting in demanding temperature control requirements, whilst ensuring the use of hydrogen is managed carefully due to its high risk of fire and explosion.

Challenges in Hydrogenation

Modern hydrogenation workflows face critical obstacles that impact efficency,safety and scalability

Testimonials

What our Customers Say

"Cranfield University is working with H.E.L group on the design and manufacture of custom automated synthesisers for production of artificial ”Plastic Antibodies”. By combining the expertise from Cranfield University on the synthetic process with automation and custom fabrication know-how of H.E.L, a range of synthesisers were produced, including a new near-production prototype. Our experience with the new automated reactor/synthesiser showed that it can perform reproducible synthetic cycles under controlled conditions and with minimal operator input."

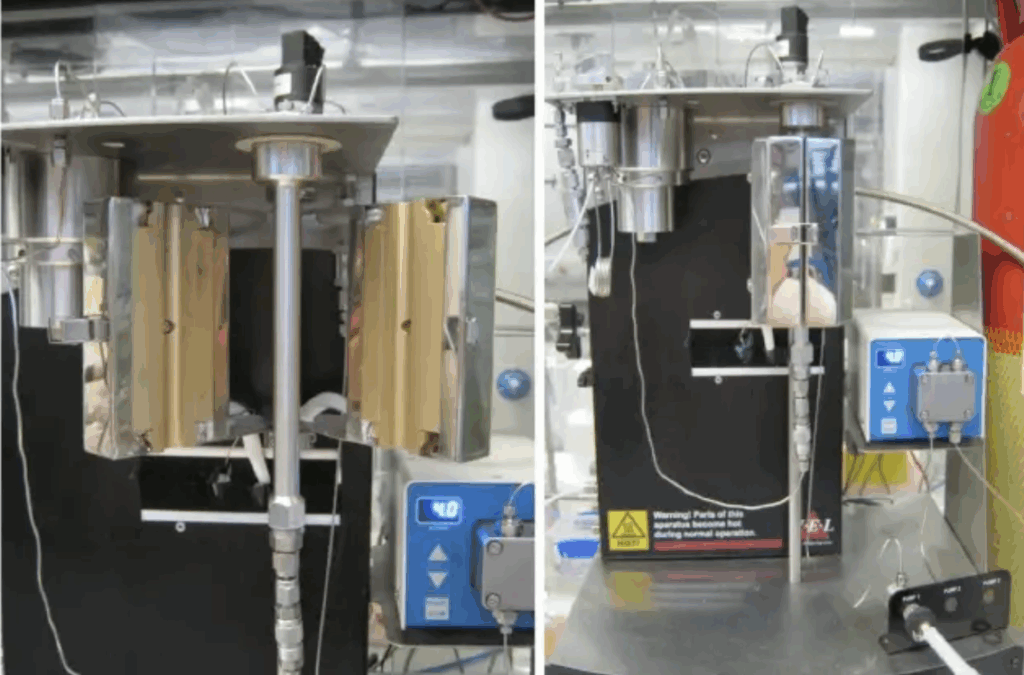

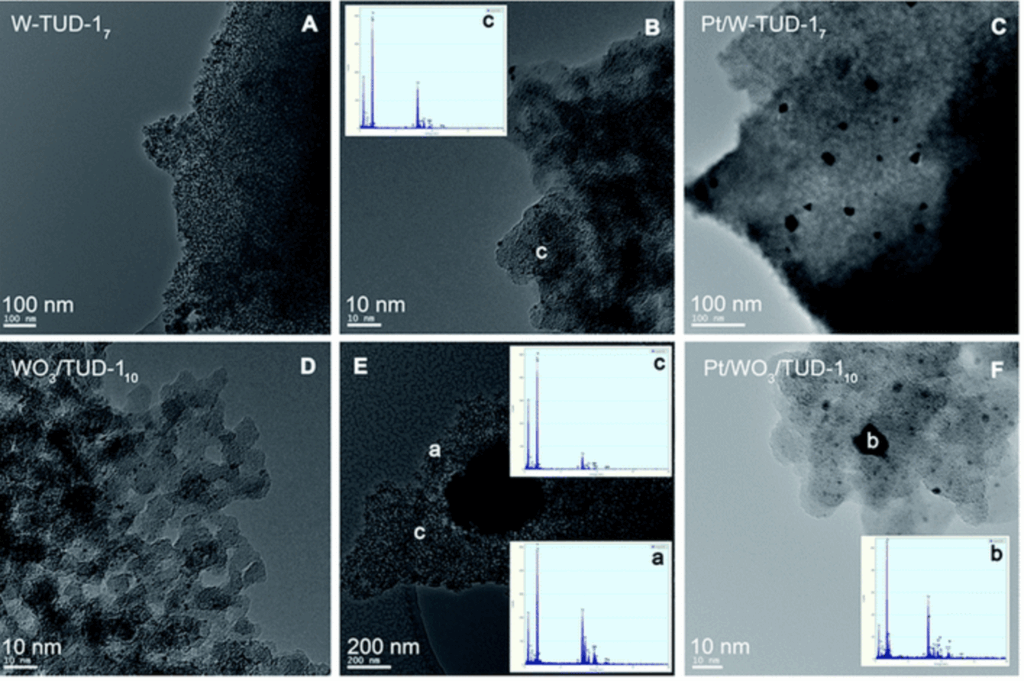

Applications & Case Studies

Our catalysis and hydrogenation instruments are used across multiple industries where safety and performance are critical

Choose the Right Solution

Compare our flagship models to find the perfect match for your research and testing requirements

| Features |

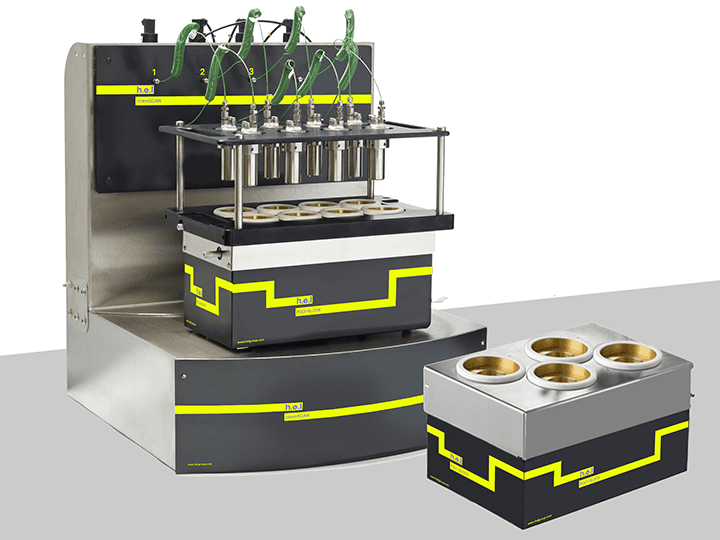

ChemSCAN

Rapid Screening of high pressure reactions and catalysts

|

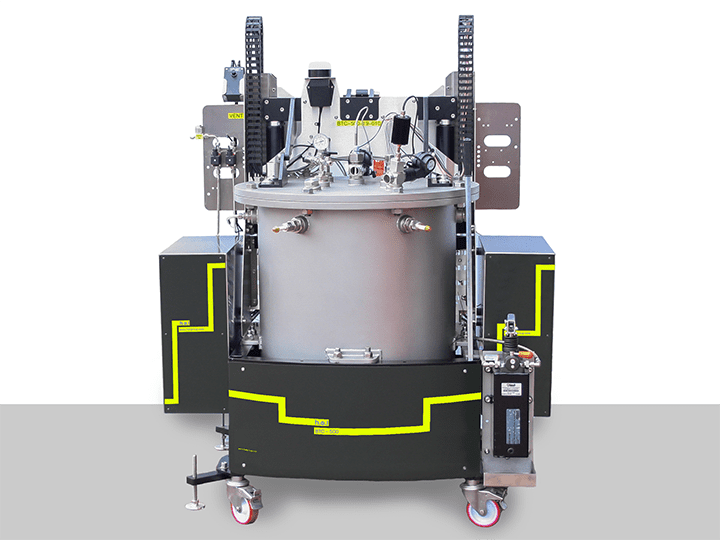

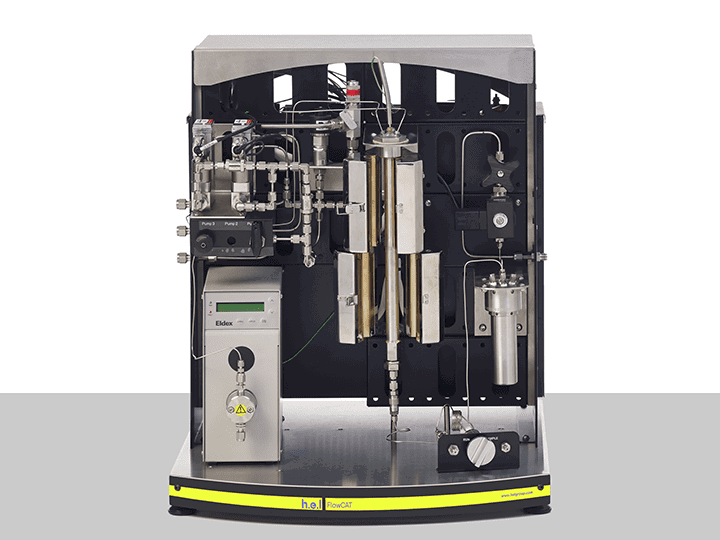

FlowCAT

High Pressure Flow Catalysis Platform

|

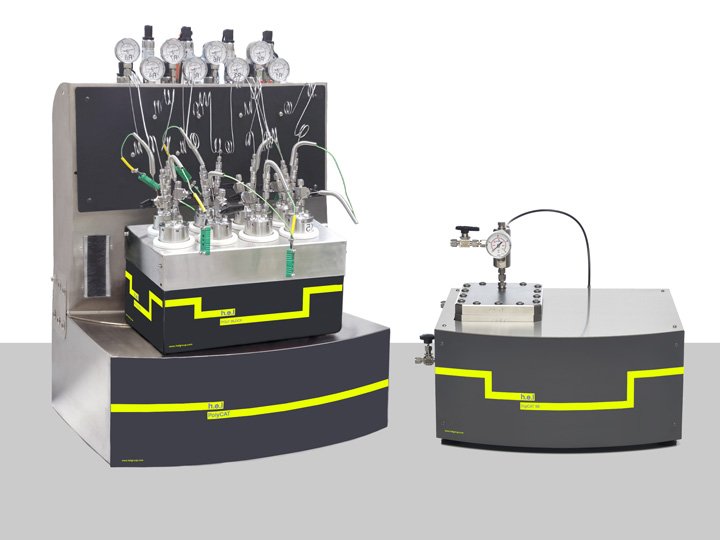

Catalyst Screening Manual Systems |

|---|---|---|---|

| Type | Parallel batch reactors (high pressure) | Continuous flow reactor | Batch microreactors (up to 96 vials) |

| Ideal For | Parallel high-throughput screening | Continuous hydrogenation development | Ultra-high throughput screening |

| Pressure Range | Up to 100 bar (optional 200 bar) | Up to 100 bar (standard) | Up to 100 bar |

| Temperature Range | -40 to 200°C (application-dependent) | Up to 300°C | Ambient to 200°C |

| No. of Reactors | up to 8 independently controlled reactors zones | 1 tubular reactor | 24, 48, or 96 vials (in single reactor) |

| Scalability | 3 mL to 400 mL (reactor dependent) | From mg to continuous gram-scale | Sub-mL scale for initial screening |

| Software |

|

|

|

| Best Use Case | Studying catalyst / gas / solvent interactions in batch | Optimising continuous hydrogenation protocols | Rapid screening of catalyst libraries |

About H.E.L Group

For over 30 years, H.E.L Group has been at the forefront of innovative scientific instrumentation for battery testing and safety analysis, serving researchers and manufacturers worldwide.

Our team of engineers and scientists combines deep expertise in electrochemistry, thermal analysis, and precision measurement to develop instruments that set the standard for battery testing excellence.

- ISO 9001 Certified

- Global Support Network

- 30+ Years Experience

- Continuous Innovation