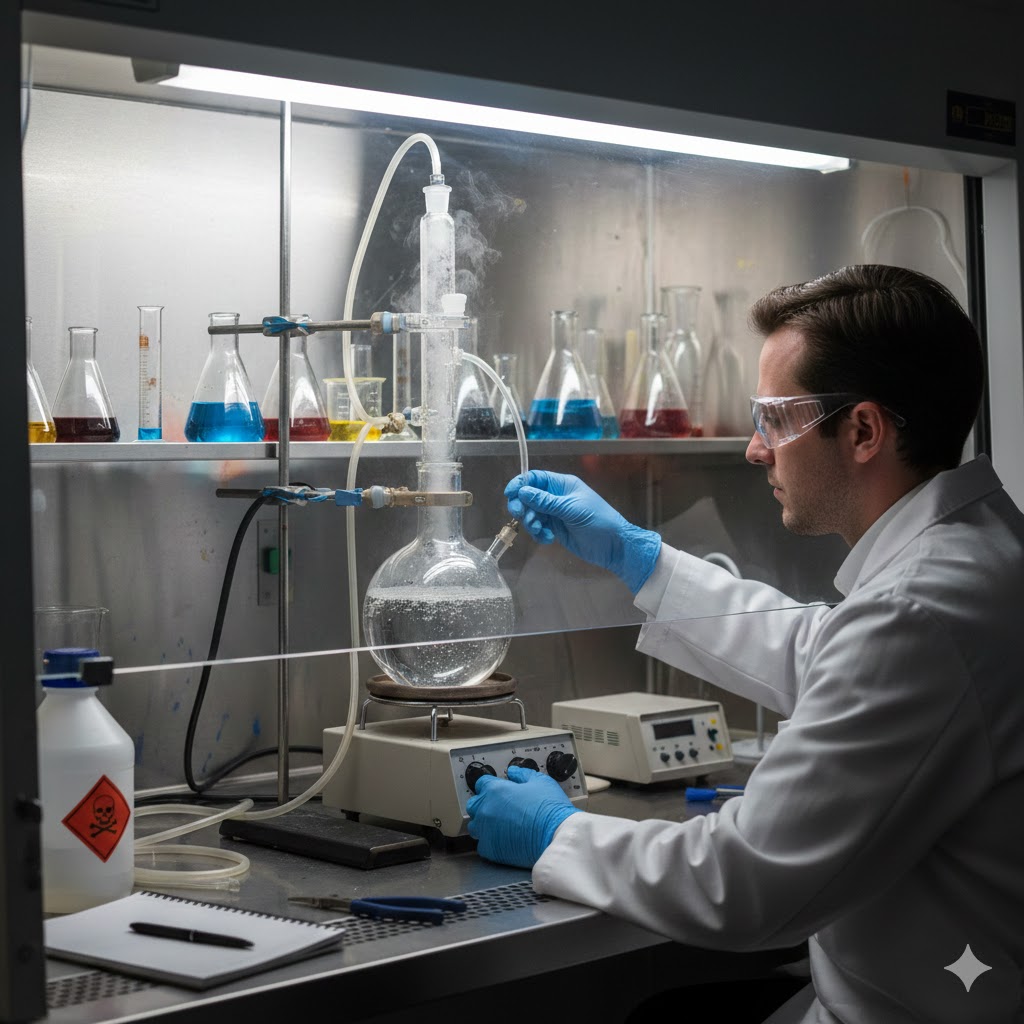

Dr. Stephan stared at the bank of six traditional high-pressure reactors. Days blurred into weeks, and his team’s progress in finding the optimal catalyst for their new sustainable process was slow and expensive. Each experiment demanded meticulous manual setup, long hours of monitoring, and then painstaking data extraction. It was the bottleneck of their entire R&D pipeline.

“There has to be a better way,” he murmured, watching a colleague wrestle with a heavy gas cylinder. The process was safe, thanks to rigorous protocols, but it was anything but efficient. The company needed results faster, and Stephan was determined to deliver.

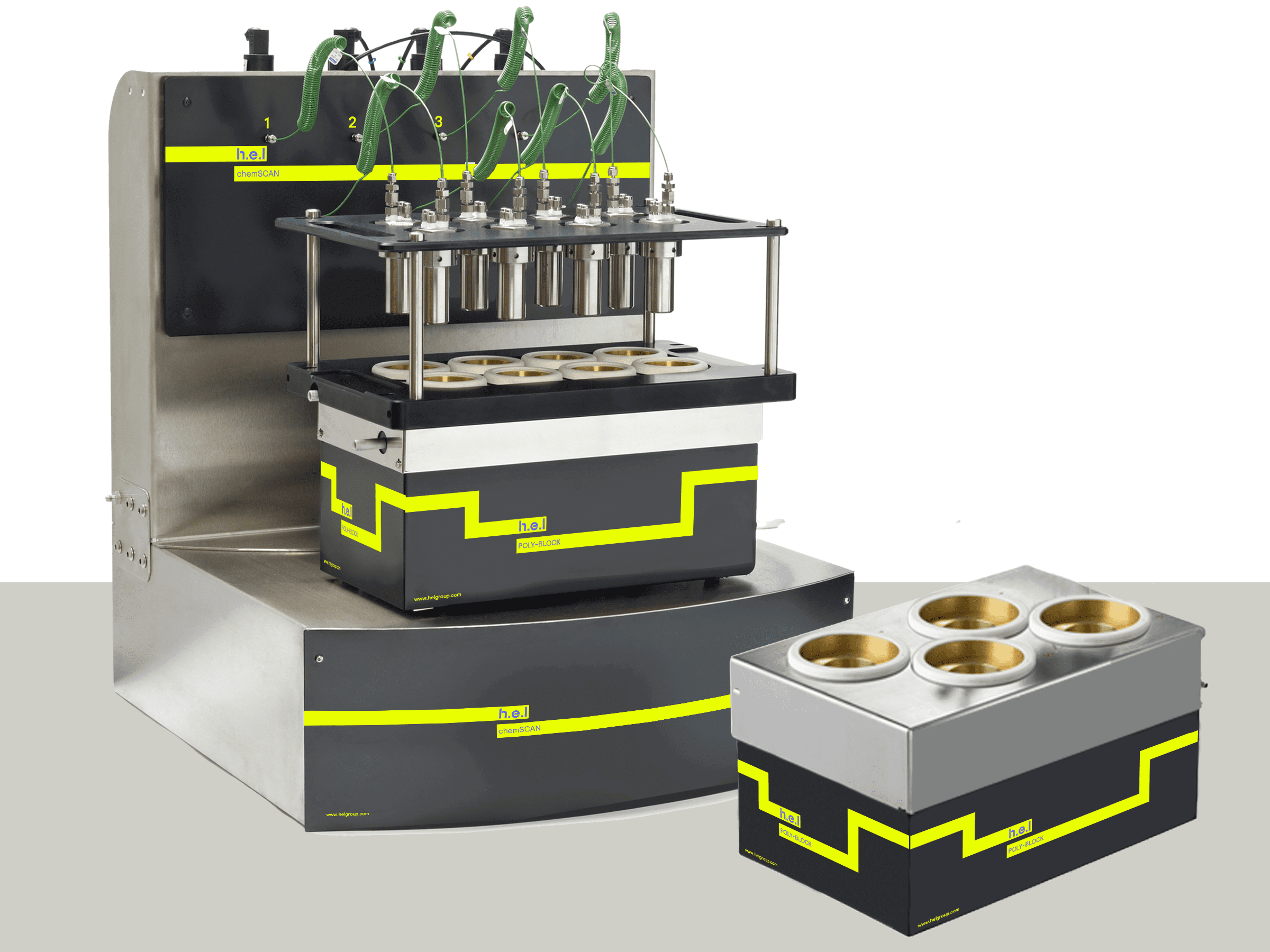

Then he found the H.E.L ChemSCAN. It wasn’t just a piece of equipment; it was a promise of a new workflow.

The Bottleneck Breaks

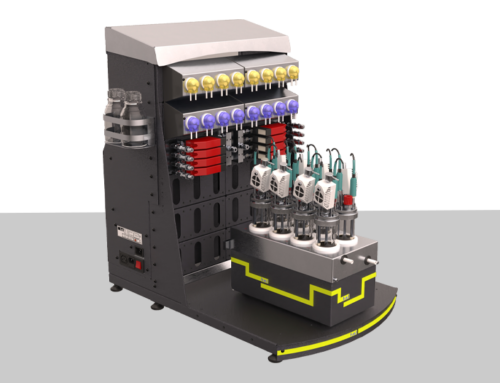

The ChemSCAN arrived, a compact, intelligent-looking unit that belied its power. It offered eight independent reaction zones in a single benchtop footprint, all capable of handling high pressure (up to 200 bar) and temperature.

Stephan gathered his team and was happy as they were not running one reaction at a time anymore. They are running eight different conditions simultaneously.

Instead of the old “one variable at a time” approach, they designed a powerful Design of Experiments (DoE) matrix. The software, an intuitive interface that connected every sensor, guided them through the setup, ensuring safety parameters were locked in before the first valve opened.

The Limitations of Traditional Screening

Manual catalyst screening methods often involve running a single experiment at a time, making the exploration of diverse variables (temperature, pressure, catalyst type, concentration) a slow and resource-intensive endeavor.

Key challenges include:

- Low Throughput – Evaluating a wide range of parameters sequentially significantly extends the development timeline.

- Inconsistent Data – Manual processes introduce human error, impacting data reproducibility and reliability.

- Safety Concerns – High-pressure and high-temperature reactions can pose safety risks with manual handling.

- Limited Data Depth – Real-time monitoring of critical reaction parameters like gas uptake is often difficult to achieve with high accuracy.

A Platform for Diverse Applications

The ChemSCAN didn’t just save time; it transformed their research. The versatility of the PolyBLOCK base platform means the ChemSCAN is suited for a wide range of demanding applications, including:

- Hydrogenation and Catalysis: The primary application, ideal for exploring variables in the development of new catalysts.

- Gas-Liquid Reactions: Excellent mixing capabilities ensure efficient gas uptake for reactions such as carbonylation and polymerization.

- Process Development: From early-stage screening in 3ml vessels to larger-scale optimization in 500ml reactors, the flexible vessel options support the entire R&D pipeline.

By combining parallel experimentation, intelligent automation, and comprehensive data capture, the H.E.L ChemSCAN is helping researchers push the boundaries of what’s possible in chemical synthesis, making the journey from discovery to commercialization faster, safer, and more efficient.