Discovery

How does early raw material hazard screening speed up the decision process?

Rapid hazard screening of raw materials at the front end of development allows earlier decisions to be made on how to develop the desired reaction and the synthetic route.

It is vital to know early in product development if the raw materials are likely to have thermal stability issues, such as the production of non-condensable gases, which could pose an explosion risk on scale-up.

Key questions to answer are:

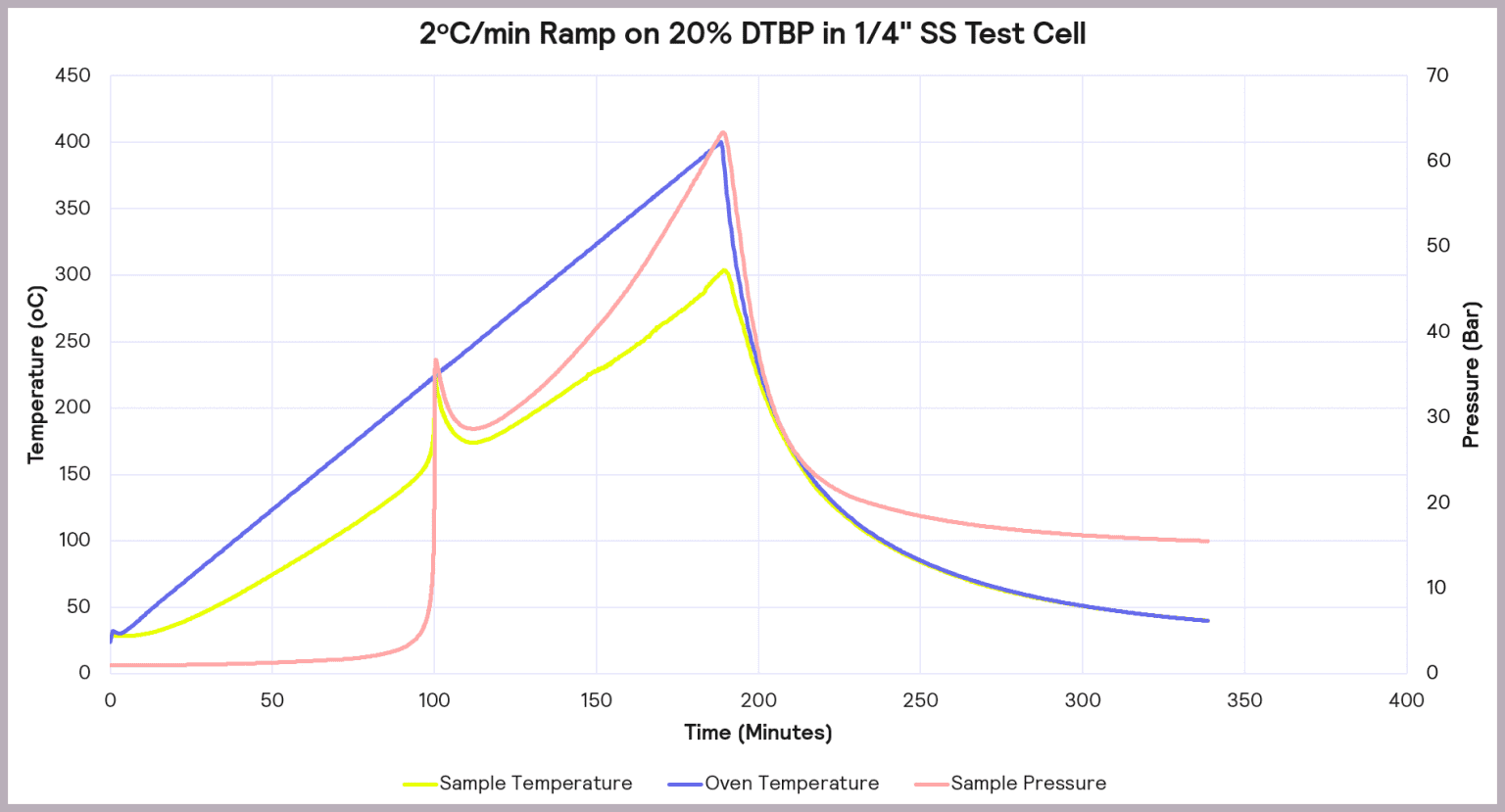

- What is the thermal decomposition profile of the raw material? In particular, does the decomposition of the raw material start to increase significantly at a ‘low’ temperature (onset decomposition temperature)? If the desired synthesis reaction reaches this onset temperature via an initial exothermic event, this could cause the reaction to increase further in temperature, creating a secondary thermal runaway.

- Is there a rapid rate of pressure change during the exothermic event? This would indicate that the reactant could pose an over-pressurization hazard during a thermal runaway.

Micro-scale calorimetry is typically used to perform a quick screening assessment on the thermal properties of the raw material, with Differential Scanning Calorimetry (DSC) being the typical method. DSC is a thermoanalytical technique in which the difference in the amount of heat required to increase the temperature of a sample and reference is measured as a function of temperature. However, this method does not provide critical information on pressure change, which is vital for assessing the over-pressurization hazard. It also suffers from the challenge that representative samples cannot always be obtained. For raw, pure materials, this is less of an issue, particularly when one only needs an initial assessment on whether to proceed further with the material. However, it becomes more significant as one moves to screening reaction mixes and further into process development, and rapid screening of larger sample sizes is required. This is especially true for poorly mixed samples and slurries.

Solutions

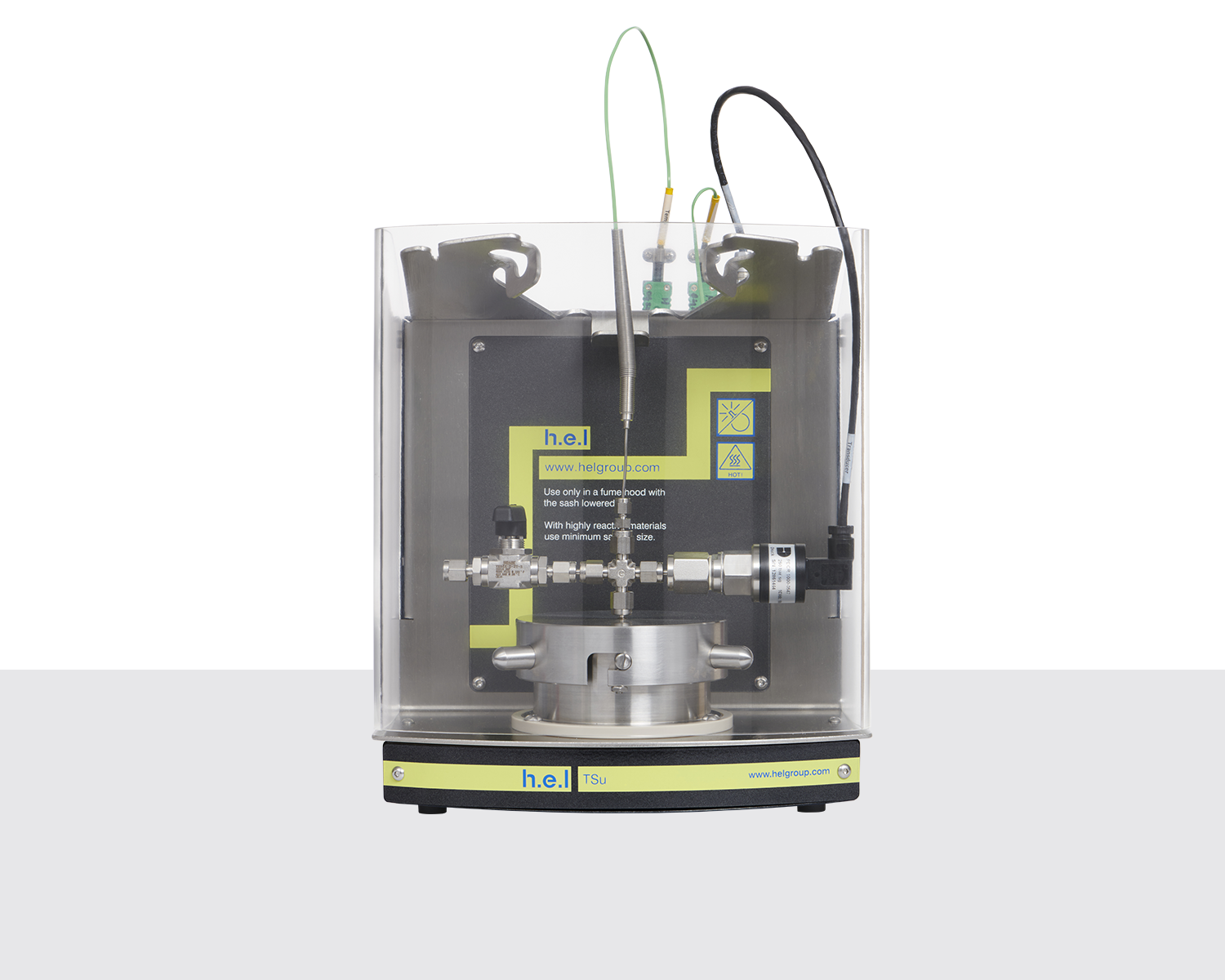

The TSu (thermal screening unit) is designed to record both pressure and temperature data allowing an in-depth characterization of the chemical reaction of interest. Both temperature and pressure can be dangerous in industrial processes since hot equipment can result in burns and injuries, but over-pressurized equipment can cause deadly explosions. Fundamental parameters, such as the onset temperature of decomposition (Td) and the rate of pressure increase, can be easily determined, enabling the hazard assessment of the material used and providing critical information for process safety. It is designed to be compact and easy to use but allows the user a larger sample mass and, consequently, a more accurate model for production scale. Its wide range of temperatures means that it can easily determine the onset temperature of decomposition. TSu’s rapid sample turn-around helps to make it a cost-effective unit, reducing the running cost.

TSu | Thermal and Pressure Hazard Screening Platform

The fast screening of thermal and pressure hazards can be performed with the Thermal Scree...