Development

What are the challenges in optimizing conditions for crystal growth and purity during development?

The main driving force in the crystallization process is the solubility of the compound of interest. The solubility depends on a range of variables:

- Solvent(s): due to the interaction with the solutes, solvents can stabilize or destabilize different crystal forms. For instance, solvents that strongly interest the molecule of interest can enhance the solubility of the crystal by interfering with the intermolecular bonds within the solute and vice versa. In multi-solvent systems, the solvent ratio can drastically affect the polarity of the medium and consequently affect the solubility, leading to different crystal forms.

- Temperature: although an increase in temperature generally tends to favor the solubility of solids in liquid, this is not universal. Temperature changes also influence the nucleation and growth rate of crystals. Thermodynamics dictates that at higher temperatures, the molecular motion increases, which, in turn, can drastically affect crystal quality and size distribution.

- pH: the pH of a solution will impact the charge state of solute molecules, especially in the case of ionic compounds or molecules that contain ionizable groups. Changes in the ionic state will affect the solubility of the molecule. Additionally, pH can affect nucleation processes due to its influence on the electrostatic interaction between atoms and molecules.

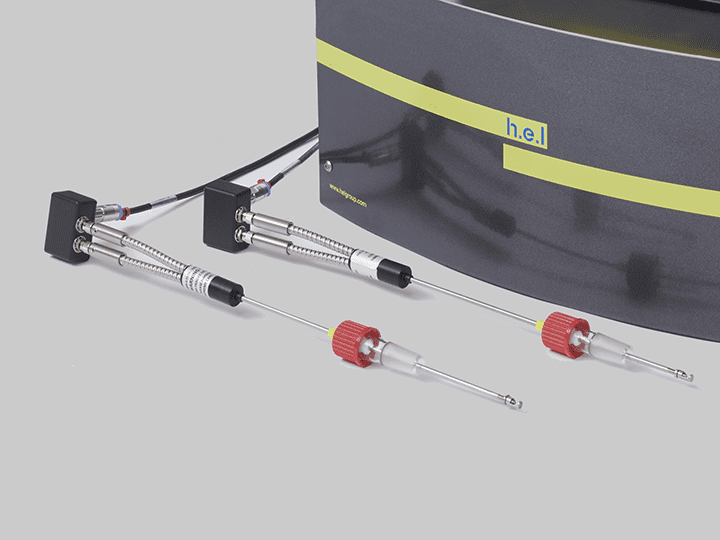

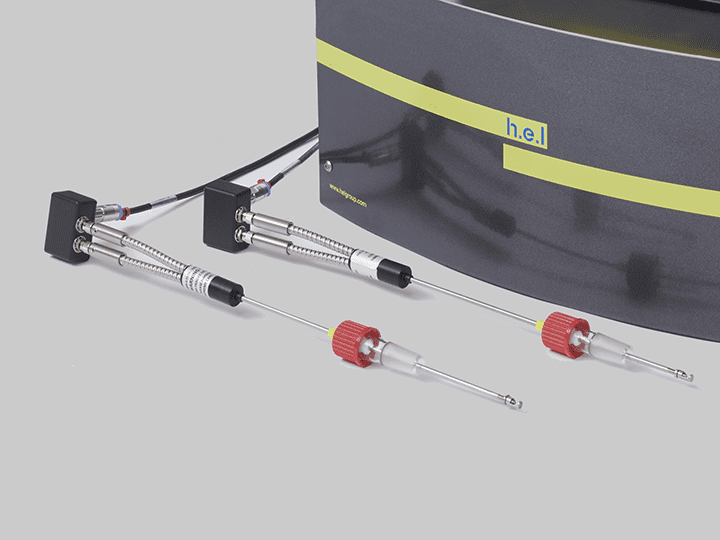

CrystalEYES | Crystallization Monitoring Sensor

Easily Determine Solubility… The need to study crystallization is widespread in the che...

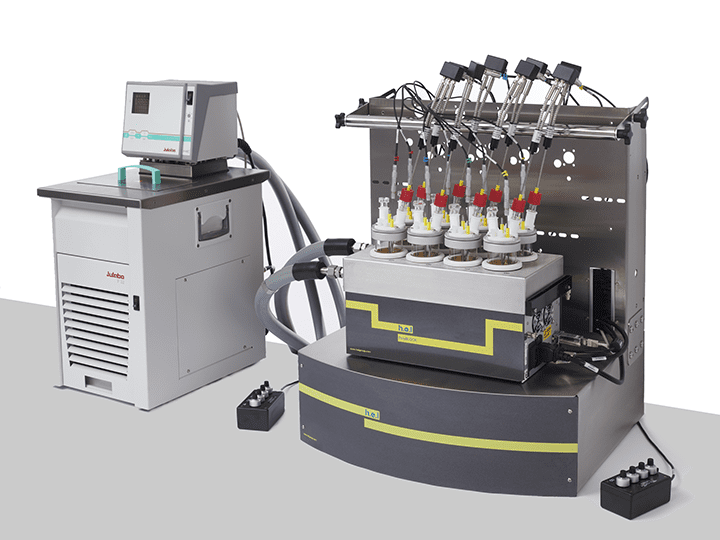

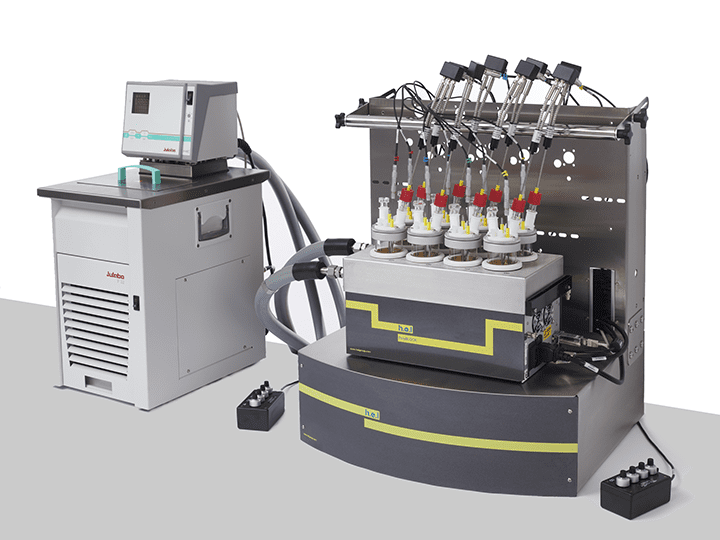

CrystalSCAN | Parallel Crystallization Monitoring Platform

The CrystalSCAN is a bench-top, automated, parallel crystallization monitoring platform, f...

How can efficiency be increased in this phase?

While significant efforts have been directed toward increasing the throughput of the screening phase, the development phase has not received the same level of attention. In the screening phase, as previously discussed, the primary focus was identifying physical and chemical conditions favorable for crystal formation. However, the focus shifts on this second phase towards refining these conditions to optimize crystal production3,4.

To increase the efficiency of this phase, it is crucial to design matrixes that encompass the conditions that will impact nucleation and crystal growth. This can include different solutions, solvents, pH levels, and temperatures. To make it effective, these designed arrays must systematically modify the physicochemical variables to fine-tune the crystallization environment. Some approaches start with broad, coarse rangers that are adjusted more granularly and precisely until the desired crystal volume and quality are achieved.3

By methodically refining these variables, researchers can develop optimized crystallization processes that yield higher volumes of suitable crystals, thereby enhancing the overall productivity and efficacy of the development phase.

Solutions

While significant efforts have been directed toward increasing the throughput of the screening phase, the development phase has not received the same level of attention. In the screening phase, as previously discussed, the primary focus was identifying physical and chemical conditions favorable for crystal formation. However, the focus shifts on this second phase towards refining these conditions to optimize crystal production3,4.

To increase the efficiency of this phase, it is crucial to design matrixes that encompass the conditions that will impact nucleation and crystal growth. This can include different solutions, solvents, pH levels, and temperatures. To make it effective, these designed arrays must systematically modify the physicochemical variables to fine-tune the crystallization environment. Some approaches start with broad, coarse rangers that are adjusted more granularly and precisely until the desired crystal volume and quality are achieved.3

By methodically refining these variables, researchers can develop optimized crystallization processes that yield higher volumes of suitable crystals, thereby enhancing the overall productivity and efficacy of the development phase.

CrystalEYES | Crystallization Monitoring Sensor

Easily Determine Solubility… The need to study crystallization is widespread in the che...

CrystalSCAN | Parallel Crystallization Monitoring Platform

The CrystalSCAN is a bench-top, automated, parallel crystallization monitoring platform, f...