Development

How can efficiency be increased in this phase?

While significant efforts have been directed toward increasing the throughput of the screening phase, the development phase has not received the same level of attention. In the screening phase, as previously discussed, the primary focus was identifying physical and chemical conditions favorable for crystal formation. However, the focus shifts on this second phase towards refining these conditions to optimize crystal production3,4.

To increase the efficiency of this phase, it is crucial to design matrixes that encompass the conditions that will impact nucleation and crystal growth. This can include different solutions, solvents, pH levels, and temperatures. To make it effective, these designed arrays must systematically modify the physicochemical variables to fine-tune the crystallization environment. Some approaches start with broad, coarse rangers that are adjusted more granularly and precisely until the desired crystal volume and quality are achieved.3

By methodically refining these variables, researchers can develop optimized crystallization processes that yield higher volumes of suitable crystals, thereby enhancing the overall productivity and efficacy of the development phase.

Solutions

While significant efforts have been directed toward increasing the throughput of the screening phase, the development phase has not received the same level of attention. In the screening phase, as previously discussed, the primary focus was identifying physical and chemical conditions favorable for crystal formation. However, the focus shifts on this second phase towards refining these conditions to optimize crystal production3,4.

To increase the efficiency of this phase, it is crucial to design matrixes that encompass the conditions that will impact nucleation and crystal growth. This can include different solutions, solvents, pH levels, and temperatures. To make it effective, these designed arrays must systematically modify the physicochemical variables to fine-tune the crystallization environment. Some approaches start with broad, coarse rangers that are adjusted more granularly and precisely until the desired crystal volume and quality are achieved.3

By methodically refining these variables, researchers can develop optimized crystallization processes that yield higher volumes of suitable crystals, thereby enhancing the overall productivity and efficacy of the development phase.

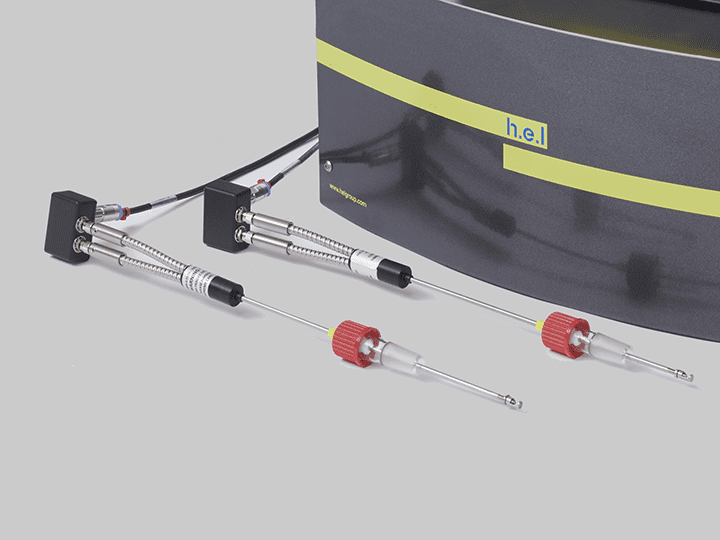

CrystalEYES | Crystallization Monitoring Sensor

Easily Determine Solubility… The need to study crystallization is widespread in the che...

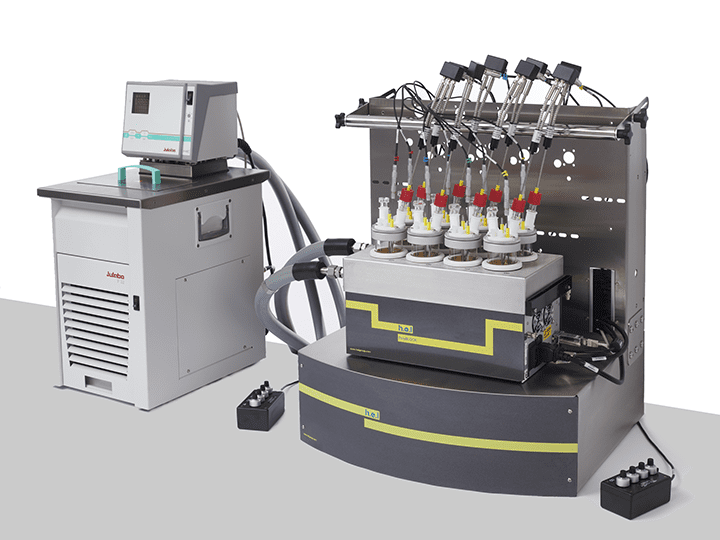

CrystalSCAN | Parallel Crystallization Monitoring Platform

The CrystalSCAN is a bench-top, automated, parallel crystallization monitoring platform, f...