Meet Global Safety Standards

Our battery accelerating rate calorimeters are designed to meet the latest battery safety testing guidelines and regulations.

Supported Standards

Supported Test Types

- MCp

- Overload

- Overcharge

- Short Circuit

- Over-Current

- Over-Discharge

- Thermal Stability

- Forced Discharge

- Propagation Point

- Thermal Runaway

- Partial Short Circuit

- External Short Circuit

- Rapid Charge/Discharge

- Adiabatic Temperature Rise

Testing Applications

Our battery testing instruments are used across multiple industries where battery safety and performance are critical

Superior Battery Testing Capabilities

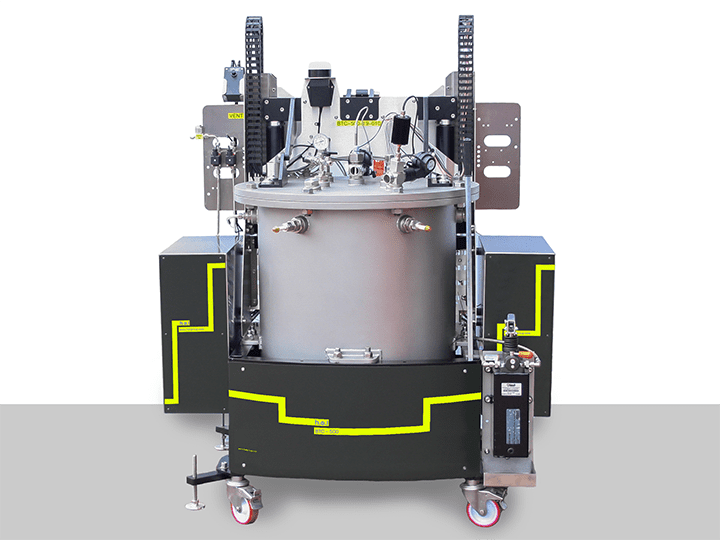

Our adiabatic calorimeters combine precision engineering with powerful software to deliver unparalleled safety testing capabilities for battery research and testing labs.

Choose the Right Testing Solution

Compare our flagship models to find the perfect match for your research and testing requirements

| Features |

BTC-130

Component & Low Capacity Testing

|

BTC-500

Large Cell & High Capacity Testing

|

|---|---|---|

| Recommended Ah range | Up to 5 Ah (LFP/NMC 622) | 50 mAh to 150 Ah (NMC 955) / 200 (NMC 811) / 250 (NMC 622) / 320 Ah (LFP) |

| Suitable Testing for | Cell Components Coin Cells 18650, Small Cylindrical Cells Small Pouch Cells |

Cell Components Coin Cells 18650, Small Cylindrical Cells Small Pouch Cells Large Pouch, Prismatic, Cylindrical Cells |

| Test chamber size (Æ x h) | 130 x 200 mm | 500 x 500 mm |

| Footprint | 700 x 600 x 800 mm | 1200 x 900 x 1980 mm |

| Max Temperature Measurement | 500°C | 1200°C |

| Exotherm Detection Sensitivity | 0.02°C/min | 0.02°C/min |

| Data Sample Rate | 10 Hz (10 kHz option) | 10 Hz (10 kHz option) |

| Video Camera | option (5MP, 30 FPS) |

|

| MCp determination | option | option |

| Best For | Battery Safety Certification High-Capacity Applications Measure large cell self-heating |

R&D Small Cell Thermal Runaways Cell Chemistry Characterization |

About H.E.L Group

For over 30 years, H.E.L Group has been at the forefront of innovative scientific instrumentation for battery testing and safety analysis, serving researchers and manufacturers worldwide.

Our team of engineers and scientists combines deep expertise in electrochemistry, thermal analysis, and precision measurement to develop instruments that set the standard for battery testing excellence.

- ISO 9001 Certified

- Global Support Network

- 30+ Years Experience

- Continous Innovation