Automation and high-throughput experimentation are increasingly demanding in modern bioprocess development strategies. With advances in genetic engineering, diverse microbial hosts have been developed as chassis for the production of innumerable natural products, pushing their metabolic limits in batch, fed-batch, or continuous fermentations (chemostats, turbidostats, perfusion, or auxostats) that take several days to complete. These production strategies are evolving to maximize rates and minimize working times and human intervention through automation. These demands are well known at the Chair of Bioprocess Engineering at Technical University of Berlin (TU Berlin), and led to the development of a fully automated platform for microbial bioprocesses in the KIWI-biolab, in which our BioXplorer 100 serves as the operational core.

Integration of the BioXplorer 100 into a Fully Automated Lab Environment

The KIWI-biolab focuses on establishing model-based automation of bioprocesses and analytics, and the intelligent linking of hardware and automation plays a key role in achieving this goal.

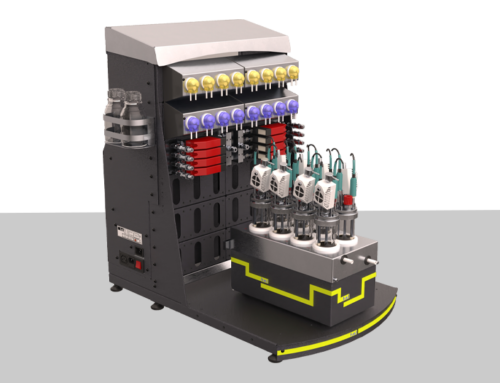

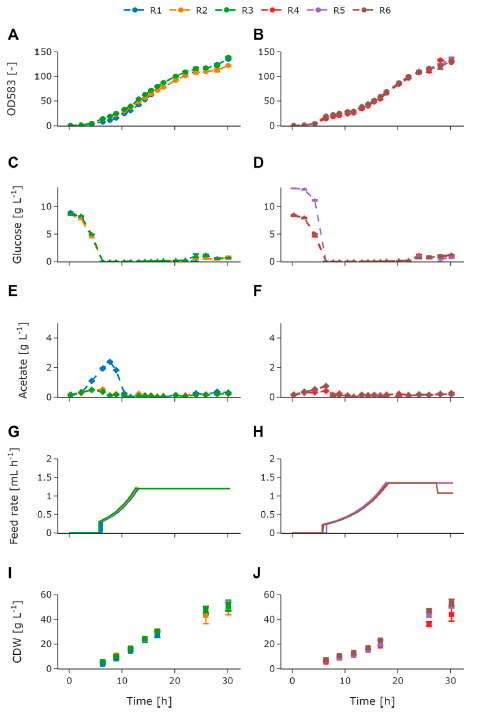

This is why the KIWI-biolab built the BioXplorer Facility, an automated platform where our BioXplorer 100 functions as the core, capable of performing fermentations continuously for up to seven days. This platform significantly reduces manual intervention, improves reproducibility, and generates high-resolution data across a wide range of experimental conditions, while cultivating diverse microbial strains, mainly Pichia pastoris and Escherichia coli.

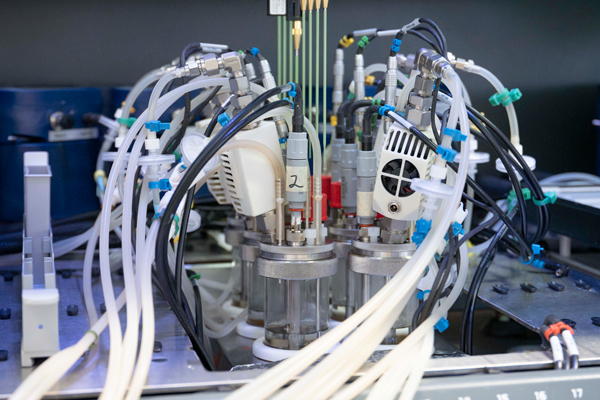

The capabilities of the BioXplorer Facility have been applied to numerous projects, including cultivations aiming at vaccine antigens or antibody production, as well as enzyme synthesis, such as glucose oxidase. To achieve these goals, the fed-batch fermentation strategies implemented at KIWI-biolab require tight control of liquid additions. Here, the liquid-feed module of the BioXplorer 100 plays a key role, in which continuous and pulse-based feeding plans deliver diverse solutions (acid and base for pH control, glucose or glycerol-based media, methanol, etc.) during fermentations lasting up to 50 hours. Likewise, some of these bioprocesses include steps in which the temperature varies between 20 and 37 °C. These cultivation conditions at temperatures lower than room temperature are easily achieved and controlled by the BioXplorer 100 via full integration with a Huber Minichiller. In addition, the parallel reactor platform integrates off-gas analysis via BlueSens sensors.

The BioXplorer 100 is also integrated into a robotic laboratory environment that supports flexible fermentation and analytical workflows. This includes a Tecan Freedom Evo 150 liquid-handling station that enables automated liquid sampling and additional pulse additions of, among other solutions, IPTG to induce plasmids and gene expression of engineered strains or magnesium supplements to the cultures.

Integration with Advanced and High-Throughput Analytical Technologies

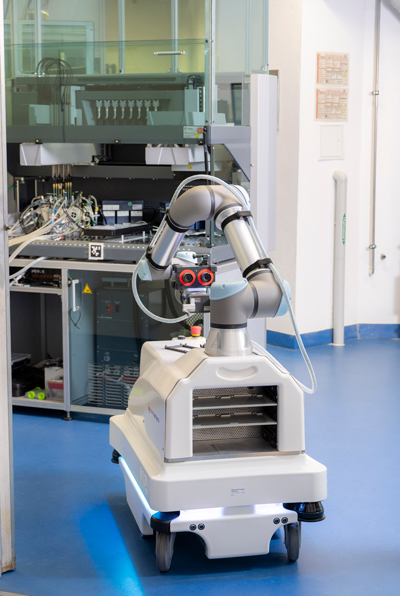

High-quality bioprocess research depends not only on fermentation automation but also on access to reliable analytical data. At KIWI-biolab, the mobile robotic lab assistant – MiLA supports sample transfers to high-throughput analytic platforms. The liquid samples collected during cultivation by the Tecan Freedom Evo 150 liquid-handling station are analyzed with high-tech analytical techniques. For example, the Cedex Bio HT measures process-relevant parameters such as glucose, glycerol, acetate, magnesium, ammonia, etc., while the two-dimensional HPLC QTOF determines concentrations of other substrates and metabolites present in the culture medium.

This automated infrastructure results in a tightly integrated workflow capable of producing high-resolution data that helps the KIWI-biolab researchers to better understand the strain metabolism and their bioprocesses, supporting a systematic process optimization, focusing on data interpretation rather than routine manual sampling and offline measurements.

Adaptive Platform Development Through Technical Support and Customization

With H.E.L Group’s experience in automated systems was a key advantage for the KIWI-biolab while building their platform. The BioXplorer 100 was seamlessly integrated into the existing laboratory infrastructure, offering an all-in-one solution.

With the integration of our high-throughput automated fermentation system into the KIWI-biolab’s automated liquid-handling station and high-throughput analytics equipment, the lab members have significantly expanded the platform’s functionality, increasing the screening efficiency of a wide range of experimental conditions for microbial bioprocesses.the integration of our high-throughput automated fermentation system into the KIWI-biolab’s automated liquid-handling station and high-throughput analytics equipment, the lab members have significantly expanded the platform’s functionality, increasing the screening efficiency of a wide range of experimental conditions for microbial bioprocesses.

The support provided by H.E.L Group’s technical team during and after commissioning, along with customized software developments and function extensions, enabled the platform to be adapted to changing research methodologies, ensuring that it could evolve in parallel with the lab’s research goals.

As bioprocess research continues to move toward automation and data-driven decision-making, the KIWI biolab’s implementation illustrates how a well-integrated experimental platform can transform and accelerate microbial process development and enable scalable, efficient research operations. This original paper describes in more detail the automated platform at KIWI-biolab.