At some point over 10,000 years, humans found themselves flabbergasted. They had been storing products, such as milk and fruit juices, and when they opened their skins and jars in which they had been keeping their precious goods, they found that they had changed. The activity of microorganisms transformed the stored products in a biological process we call fermentation. Whereas most macroscopic creatures use oxygen to oxidize the nutrients they ingest to obtain energy, fermentative organisms can use alternative routes to oxidize sugars to get the cellular power they need to live. For example, Saccharomyces cerevisiae transforms glucose in the malt into ethanol, transforming it into beer, or Lactobacillus converts lactose into lactic acid, resulting in cheese.

Humans noticed this change, and the organoleptic properties improved compared to the original product. Like they have done animals and plants, they decided to domesticate microorganisms for their benefit. Whereas animals and plants had to build pens and dig burrows, the situation is slightly different for microorganisms. Fermentative microorganisms require several conditions to thrive, for example, lack of oxygen (anaerobiosis) and high humidity. This made humans become creative and design vessels and containers that would maintain these conditions, and this was the origin of bioreactors, also known as fermentors.

The first evidence of a pottery vessel used explicitly for fermentation, and therefore we can consider the original bioreactor, dates back to 7,000 BCE in China. It was used to ferment a mix of rice, honey, and fruit. The second oldest evidence of fermentation is 1,500 years younger, found in Iran. Subsequently, other fermented products were developed, such as leavened bread in Egypt around 3000 BCE and pickled cucumber in the Tigris Valley around 2000 BCE. Although fermentations are commonly used for

culinary purposes, they can also have medicinal properties. That is what Chinese people found around 500 BCE when they discovered moldy fermented soybeans could be used to treat infected wounds. They did not know they were using penicillin, produced by a fungus. In fact, humanity needed to wait over 2,400 years until penicillin itself was discovered in a serendipitous event. Dr Ian Fleming returned from his holiday and found that some mold was contaminating his Staphylococcus cultures growing on Petri dishes. That mold, named Penicillium rubens, inhibited

the growth of bacteria by producing chemicals that prevented the other microbes from proliferating. Despite the relevance of such discovery, it was dismissed at first. It was not until Fleming et al. showed an increase in the survival of mice infected with Staphylococcus that the scientific community’s attention was drawn to this discovery. The process of penicillin at that time was painfully slow and resource-consuming, involving the production of the broth used to grow the fungus in whatever containers they could find, including bedpans and bathtubs.

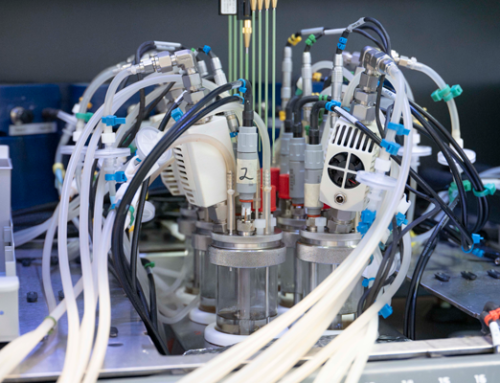

Just before the discovery of penicillin, researchers had been advancing in the developments of reactors that would be used for microbial growth. Chaim Weizmann in Manchester developed large vessels that could maintain conditions suitable for microorganisms to produce acetone, which was used for manufacturing explosives. Strauch and Schmidt developed tubing that allowed the introduction of water and steam to clean the reactors and achieve aseptic conditions. However, the need for increased penicillin production resulted in a push for the development of bioreactors. This was achieved by 1945, when using industrial reactors, 7 trillion units of penicillin were manufactured. Since then, the evolution of bioreactors has been swift. Improvements include multi-vessel systems, large-volume reactors, and sterilization processes (autoclave, freeze-dry). Until the 1990s, bacteria reigned supreme as the main aim for bioreactors; however, all the innovations that bioreactors have undergone allowed for the growth of cells belonging to other kingdoms, such as animal cells (including mammal and insect cells) and algae. The versatility of using different types of cells resulted in a broader range of products, for example, vaccines.

So, as we can see, despite modern bioreactor reactors looking shiny and new, the fundamentals of such technologies have been with humans for a long time. This long history of the interrelation between humans, microorganisms, cells, and reactors has yielded essential advances for us, and all the lessons learned throughout mean that now we have different designs for fermentors, but also various products and technologies that can help us build a healthier, more sustainable, and safer world. The bioreactors manufactured at H.E.L (BioXplorer) are a prime example of this, and have been used for removing greenhouse gases, such as CO2, or to produce biofuels in a greener way.