Automation and high-throughput experimentation are increasingly essential in modern bioprocess development, particularly when experiments run continuously for several days and generate complex, data-rich outputs. At TU Berlin, these demands led to the development of a fully automated platform for microbial bioprocesses within the Kiwi biolab, with the BioXplorer 100 serving as the central system.

Creating a Scalable and Automated Research Workflow

The primary objective in the KIWI biolab was to enable long-running microbial experiments while maintaining the ability to generate high-resolution data across a wide range of experimental conditions. To meet this goal, the team

designed an automated setup capable of operating continuously for up to seven days, significantly reducing manual intervention while improving consistency and data quality.

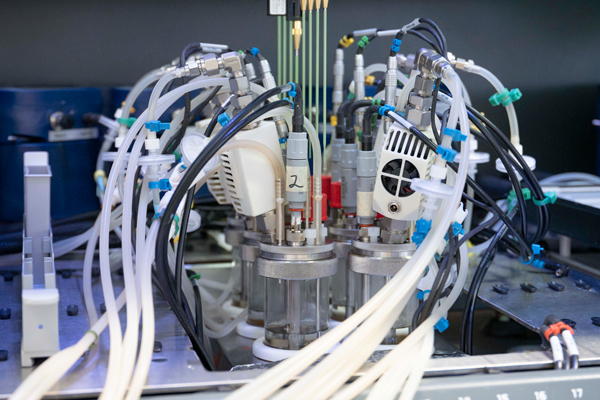

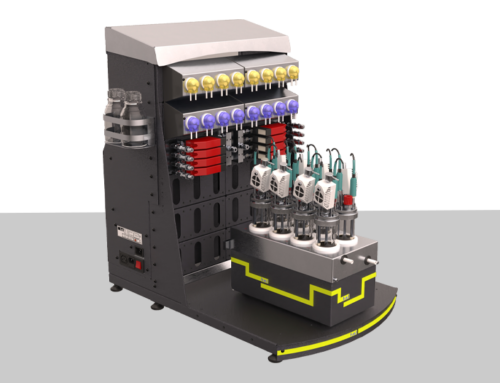

The BioXplorer 100 functions as the core of this automated workflow. Integrated into a robotic laboratory environment, the system supports flexible experimental design and execution. Its connection to a Tecan liquid-handling station enables automated sampling and handling throughout each experiment, allowing researchers to focus on data interpretation rather than routine manual tasks.

Integration with Advanced Analytical Technologies

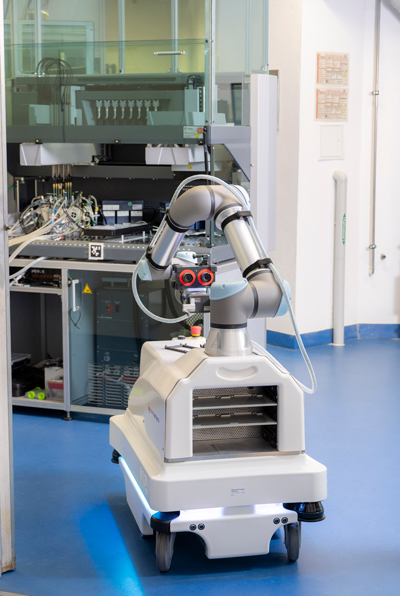

In addition to automation, seamless access to analytical data was an important requirement. The BioXplorer 100 was connected via a mobile assistant to high-throughput analytical systems, including Cedex and two-dimensional HPLC QTOF. Combined with integrated off-gas analysis, this configuration enables comprehensive monitoring of microbial bioprocess performance over extended periods.

This tightly connected workflow generates high-resolution data that provides deeper insight into process behaviour and variability, enabling both exploratory research and structured process optimisation.

An All-in-One Solution Embedded in the Laboratory Infrastructure

A key advantage for the KIWI biolab was the ability to integrate the BioXplorer 100 seamlessly into its existing laboratory infrastructure. The all-in-one solution provided by H.E.L. was embedded within the broader robotic framework, allowing the laboratory to expand its experimental capabilities without disrupting established workflows.

Equally important was the quality and responsiveness of the technical support provided. Immediate assistance, along with customized software developments and function extensions, enabled the system to be adapted to specific experimental needs. This level of support ensured that the platform could evolve alongside changing research requirements.

Supporting Efficient Screening of Microbial Bioprocesses

With automation, system integration, and high-throughput analytics working together, the KIWI biolab at TU Berlin can now efficiently screen a wide range of experimental conditions for microbial bioprocesses. The platform supports extended experiments, flexible workflows, and comprehensive data generation, all within a single integrated setup.

As bioprocess research continues to place greater emphasis on automation and data-driven decision-making, this implementation demonstrates how an integrated experimental platform can transform microbial process development into a scalable, efficient research operation.