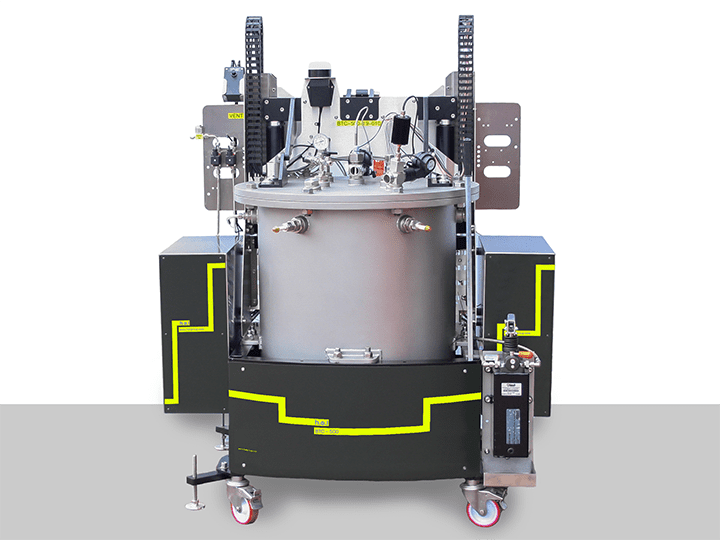

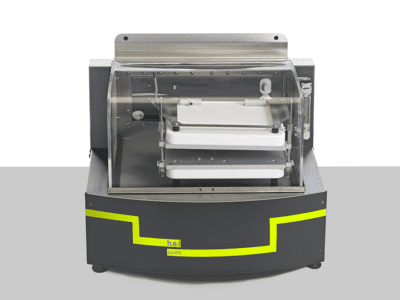

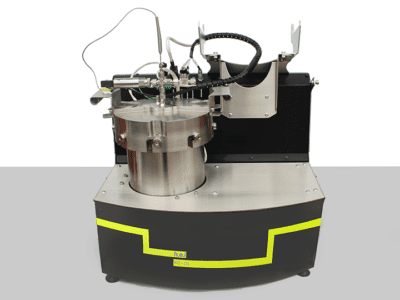

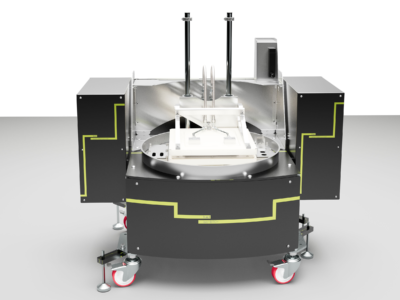

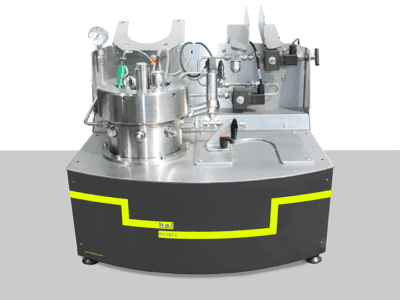

BTC-500 | Large-scale, battery testing, adiabatic calorimeter

The BTC-500 (Battery Testing Calorimeter) is a floor-standing adiabatic calorimeter for the safe testing of thermal, electrical, and mechanical stress (abuse) tests on larger battery cells, and small modules. Evaluation of these tests facilitates the assessment of the safety performance of battery cells, enables the battery’s safe operating limits to be defined, and facilitates research and development into the mechanisms of thermal runaway and thermal propagation.

- Characterizing differences in cell performance

- Defining safe operating limits

- Exploring thermal runaways and thermal propagation

Applications

Safety Testing

Define safe operating limits:

- It is essential to identify the safe operating limits of battery cells, modules, and packs in order to avert the risk of thermal runaway, and the potentially catastrophic consequences to which it could lead. Therefore, batteries need to be subjected to mechanical, electrical, and thermal stresses in order to define their safe operating limits.

- Thermal stability data from thermal stress tests can help define the safe working temperature of the battery

- The evaluation of over-charging and discharging rates allows the maximum safe voltage and maximum safe current to be determined

- The consequences of mechanical stresses and external short circuits (ESC) can be evaluated

Exploring thermal runaways and thermal propagation

- In general, most extreme conditions can result in thermal stress on the battery cell, which can lead to a thermal runaway. Therefore, for the development of safe batteries, it is essential to understand the mechanism of the thermal runaway in a cell, and how it propagates within a module or pack so that appropriate mitigation strategies can be implemented.

The data obtained from the stress tests performed in the BTC-130 and the BTC-500 can be used to model a cell’s predicted thermal behavior. Successive onset temperatures of decomposition of components within the cell can be detected, and the resultant heat released determined. This can help to facilitate a mechanistic understanding of the thermal runaway within the cell. Further insight can also be derived from the external analysis of the composition of any evolved gases collected.

The BTC-500 also enables the triggering of a cell at a specific position within a module to undergo a thermal runaway with a mechanical- or electrical-induced short circuit, while the integrated camera will visually capture the event unfolding. The induced thermal runaway allows the risk of thermal propagation to be evaluated, the magnitude of the thermal event to be characterized, and appropriate mitigation measures to be implemented within the module design to ensure heat dissipation is greater than heat generation.

Performance Testing

Characterize differences in cell performance

- The BTC-130 and BTC-500 can be used to characterize the cell performance under more extreme operating conditions. The absolute limit of safe, repeated use can be assessed with the automated cycling of the battery cell until the heat generated by its discharge causes the onset of self-heating. Similarly, puncture tests provide an indication of the structural stability of the cell. The resulting thermal event can also be captured on camera on the BTC-500. These tests enable the safety performance of the cells to be compared.

Find out more in our guide Solutions in Battery Technology Testing: Hazard screening, safety testing and performance characterization

Application Notes:

On-Demand Webinars:

- Key Benefits of isothermal and adiabatic calorimetry battery testing

- The Use of Isothermal Calorimetry in Battery Performance Testing

Blogs:

- Best Publications on Battery Testing to Read Now – Part 1

- Best Publications on Battery Testing to Read Now – Part 2

Videos:

- Heat Wait Search Video Using H.E.L Battery Testing Calorimeters (BTC)

- With The H.E.L BTC 130 the maximum temperature of the environment which results in a battery thermal explosion that can be predicted by placing the sample in the BTC and performing well-established adiabatic tests. This involves stepwise heating, followed by a wait-and-search period that can be used with cells and large battery packs alike to determine the maximum safe operating temperature.

Technical Literature

The following is a list of supporting Technical Literature.

Integration of mass spectrometry to characterize the gas evolution of batteries in thermal runaways using adiabatic calorimetry.

Assessing the suitability of H.E.L’s BTC-500 for small battery testing

Publications

The following are a list of some technical publications which highlight the use of the equipment.

A comprehensive insight into the thermal runaway issues in the view of lithium-ion battery intrinsic safety performance and venting gas explosion hazards

Gang Wei, Ranjun Huang, Guangxu Zhang, Bo Jiang, Jiangong Zhu, Yangyang Guo, Guangshuai Han, Xuezhe Wei, Haifeng Dai

01-Nov-2023

https://www.sciencedirect.com/science/article/abs/pii/S0306261923010152(Subscription or purchase maybe required for full access)

Revealing the multilevel thermal safety of lithium batteries

Gaojie Xu, Lang Huang, Chenglong Lu, Xinhong Zhou, Guanglei Cui

01-Oct-2020

https://doi.org/10.1016/j.ensm.2020.06.004(Subscription or purchase maybe required for full access)

Study on the Performance of Parallel Air-Cooled Structure and Optimized Design for Lithium-Ion Battery Module

Shuai Pan, Changwei Ji, Shuofeng Wang & Bing Wang

28-Jul-2020

https://doi.org/10.1007/s10694-020-01020-x(Subscription or purchase maybe required for full access)

In-Operando Impedance Spectroscopy and Ultrasonic Measurements during High-Temperature Abuse Experiments on Lithium-Ion Batteries

Hendrik Zappen, Georg Fuchs and Alexander Gitis and Dirk Uwe Sauer

22-Apr-2020

https://doi.org/10.3390/batteries6020025(Subscription or purchase maybe required for full access)

Study on thermal stability of nickel-rich/silicon-graphite large capacity lithium ion battery

Hang Li, Xiangbang Kong, Chaoyue Liu, Jinbao Zhao

01-Oct-2019

https://doi.org/10.1016/j.applthermaleng.2019.114144(Subscription or purchase maybe required for full access)

Prediction of the heavy charging current effect on nickel-rich/silicon-graphite power batteries based on adiabatic rate calorimetry measurement

Hang Li, Chaoyue Liu, Xiangbang Kong,Jun Cheng, Jinbao Zhao

01-Oct-2019

https://doi.org/10.1016/j.jpowsour.2019.226971(Subscription or purchase maybe required for full access)

Measurements in abusive tests on lithium ion polymer cells

F. Bianchi; B. Tevenè

14-May-2015

https://doi.org/10.1109/I2MTC.2015.7151419(Subscription or purchase maybe required for full access)

Downloads

The following are a list of available downloads.

Industries and Applications

Research & Development

Advanced testing for new battery chemistries and cell designs. Optimize battery safety designs with electrolyte,…

Manufacturing Quality Control

Battery testing and quality verification in OEM factories. Uncover electrochemical and decomposition reactions sending cells…

Electric Vehicles

Safety and performance testing for EV battery cells. Validate thermal stability under real world worst…

Consumer Electronics

Quality assurance testing for batteries used in smartphones, laptops, and wearable technology. Ensure safety and…

Power Storage

Comprehensive testing for grid storage batteries and power backup systems. Ensure safety and reliability for…

Battery Safety Testing

Design Safe Battery Chemistries and Cell Components