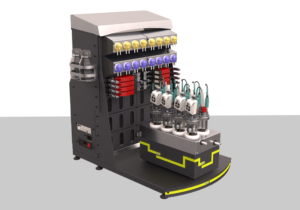

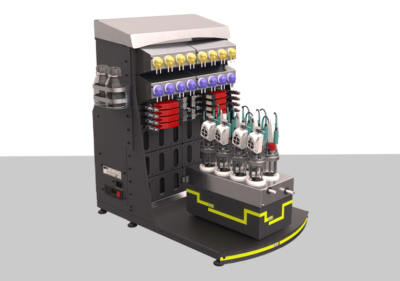

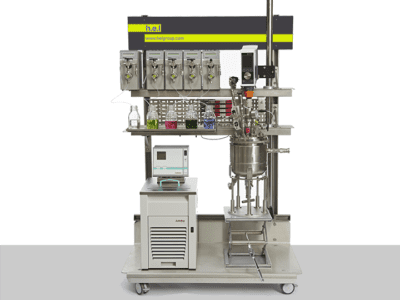

BioXplorer 400P | High-pressure bench-top, parallel 4 bioreactor platform

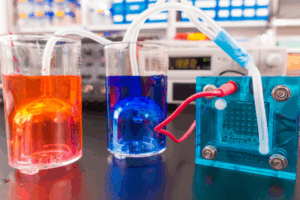

The BioXplorer 400P is an automated parallel pressure bioreactor system for the discovery and optimization of novel bioprocesses. Designed for applications ranging from syngas fermentation to cell-free enzymatically catalyzed processes, the BioXplorer 400P uses pressure and precision gas control to accelerate bioprocesses, which depend on the availability of dissolved gases.

The customizable configuration combined with versatile software allows the BioXplorer 400P to fulfill your precise needs, giving you the data you need to scale up faster.

Overview

Pressurized Bioprocessing

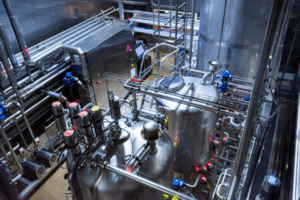

The BioXplorer 400P’s ability to run up to four parallel bioprocesses at up to 10 bar pressure is unique. More and more bioprocess scientists are turning to pressurized systems to increase the availability of dissolved gases and accelerate gas-dependent bioprocesses. The BioXplorer 400P is an indispensable tool for the optimization and scale-up of such processes. The system has been engineered with a focus on safety and ease of use. For example, the use of 2 gas spargers per reactor enables risks associated with potentially hazardous gas mixtures to be minimized. Adding pressure to accelerate your bioprocesses can deliver higher yields without compromising functionality and configurability.

Configurable System

The BioXplorer 400P uses a modular design and can be supplied with a wide range of probes, gas feeds, and liquid feeds, enabling it to be tailored to your precise needs. This maximizes functionality and ease of use while minimizing bench space requirements and cost.

Flexibility to optimize processes

The choice of probes to track the wide range of physicochemical parameters in bioprocess provides in-depth knowledge. Using H.E.L’s WinISO tight control and responsiveness, automatization of the process is possible. BioXplorer 400P can operate 4 bioreactors in parallel or independently, reducing the optimization time of bioprocesses.

Technical Literature

The following is a list of supporting Technical Literature.

Operating the BioXplorer 100 as a Turbidostat to Maximize High-Density E. coli Cultivation

Downloads

The following are a list of available downloads.

Industries and Applications

Fermentation for Sustainable Aviation Fuel (SAF)

Advance sustainable aviation fuel R&D with fermentation systems designed for CO₂, H₂, and CO gas…

CO₂-Based Biomanufacturing Platforms

Develop carbon-negative fermentation processes using CO₂ as the primary feedstock in microbial bioproduction of fuels,…

Renewable PtL Systems

Simulate Power-to-Liquid (PtL) processes for converting renewable electricity and captured carbon dioxide into liquid fuels…

Syngas Fermentation for Bioethanol Production

Optimize syngas-to-ethanol microbial conversion using precise control of gas composition, flow rates, and fermentation parameters.

Industrial Waste Gas Fermentation

Capture and integrate industrial CO, CO₂, and syngas emissions using scalable gas fermentation systems for…

Parallel Bioreactors for Gas Fermentation

Boost gas substrate availability and reduce costs in your production of biofuel & SAF.