Scale Down

Why are scaling down processes important?

Scale-down process plays a crucial role in the bioprocess industry for a number of reasons:

Process Development and Optimization: scale down processes because their capabilities to recreate large processes at a smaller scale result in cost-effective and rapid ways to test conditions, such as growth media, temperature, pH, or oxygen scale.

Understanding Process Challenges: large-scale reactors face typical problems, such as mixing or aeration, which can be overseen in the process development. These issues can significantly impact industrial production, but scale-down processes can help identify these potential challenges.

Regulatory requirements: regulatory authorities require a demonstration of process understanding and control in manufacturing. Scale-down models contribute to proving this understanding as part of the quality by design.

Two approaches arise in recreating the physical, chemical, and biological parameters that cells encounter at a large scale in small reactors.

Statistical scale-down

This approach aims to identify the critical factors influencing the process outcome and simulate their effects using statistical analysis. In this type of scale-down, lab-scale reactors are used to perform a large number of experiments to generate a matrix of variables corresponding to conditions that affect the performance of the bioprocess. This method is less time-consuming and costly, but on the other hand, it can lack the fidelity of a physical scale-down.

Generally, statistical scale-down involves designing experiments that will capture the variability of large-scale processes, followed by data collection of both the variable conditions and response variables. Based on the data, a statistical model can be constructed describing the process performance, which will finally be validated based on the accuracy of its predictions.

Physical scale-down

This approach aims to simulate large-scale conditions, mimicking heterogeneous conditions encountered in small-scale reactors. To achieve this, laboratory-scale bioreactors are engineered. These smaller-scale reactors reproduce environmental conditions and simulated physicochemical parameters, such as gradients, which will introduce heterogeneity using approaches like intermittent feed or pulsing air flow. Detailed monitoring of cell behaviors will show how they react to the different conditions in the reactor and how they affect growth, product formation, and nutrient consumption, among other parameters. The results obtained from physical scale-down will then go through an iterative optimization process, helping to improve the efficiency of the process.

Solutions

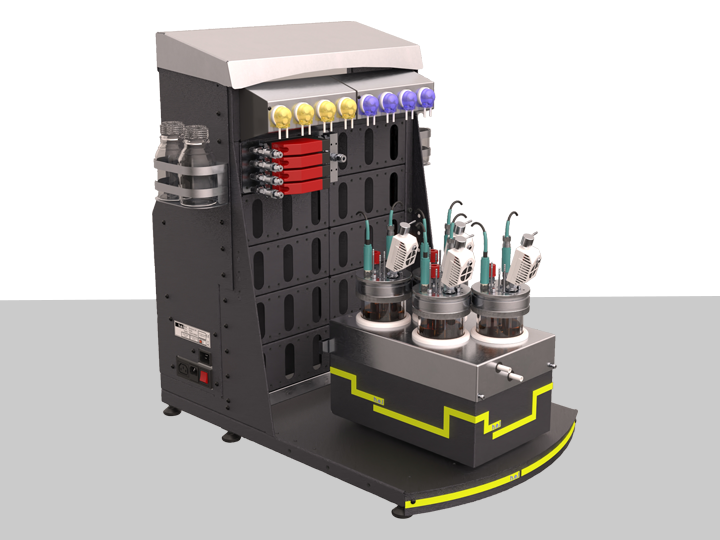

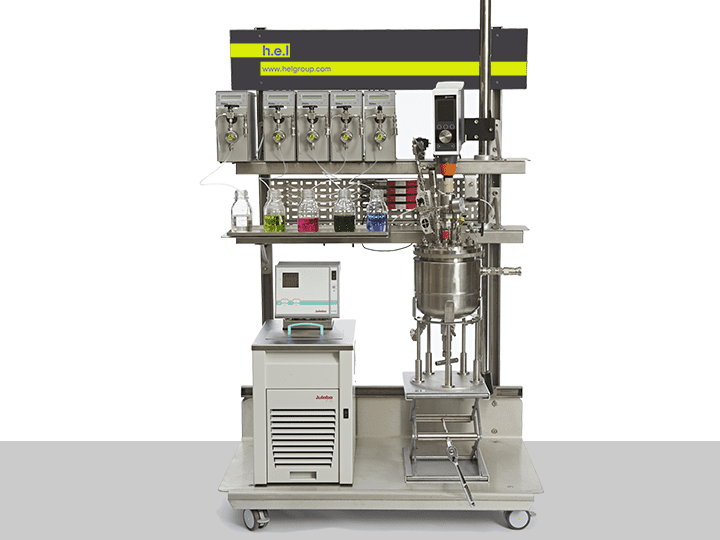

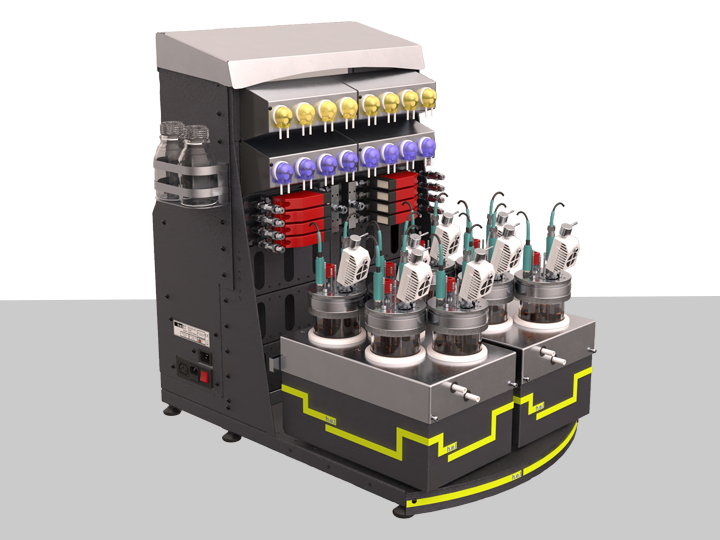

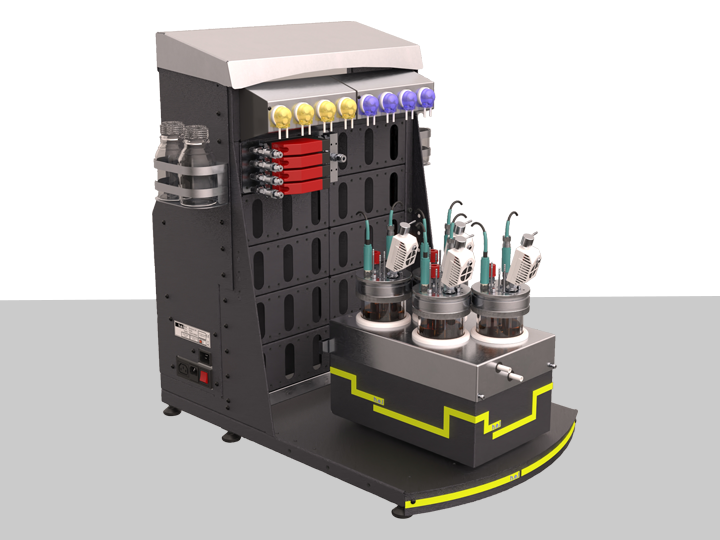

BioXplorers can play a fundamental role in scale-down process analysis. Using H.E.L’s WinISO, BioXplorer 100 and 400 can be finely controlled to replicate the conditions found at a larger scale accurately. Multiple reactors can be used to increase the throughput of the process, positioning them as a potent tool for statistical scale-down processes. On the other hand, larger reactors, such as BioXplorer 5000, can be used to replicate complex conditions, such as physicochemical gradients, and therefore can be instrumental in physical scale-down processes. The application of scale-down processes using BioXplorer models results in significant time and cost reductions, underscoring their importance in efficient and economical bioprocess management.

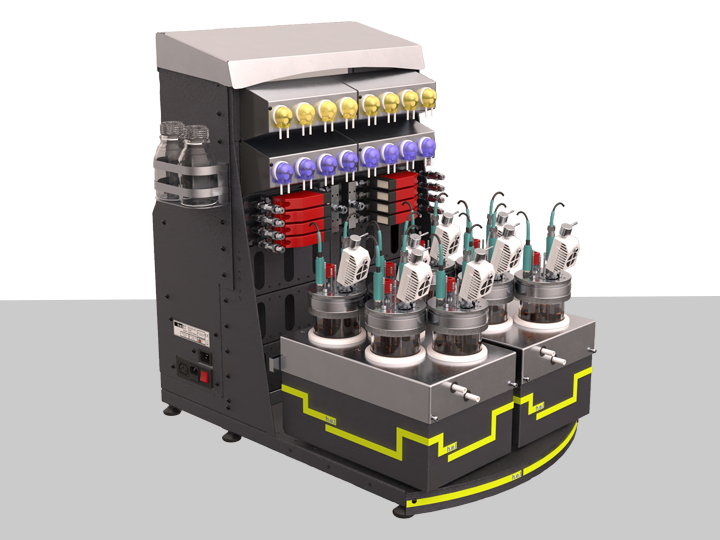

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 is equipped with 4 bioreactors with working volumes of up to 400 ml. It...

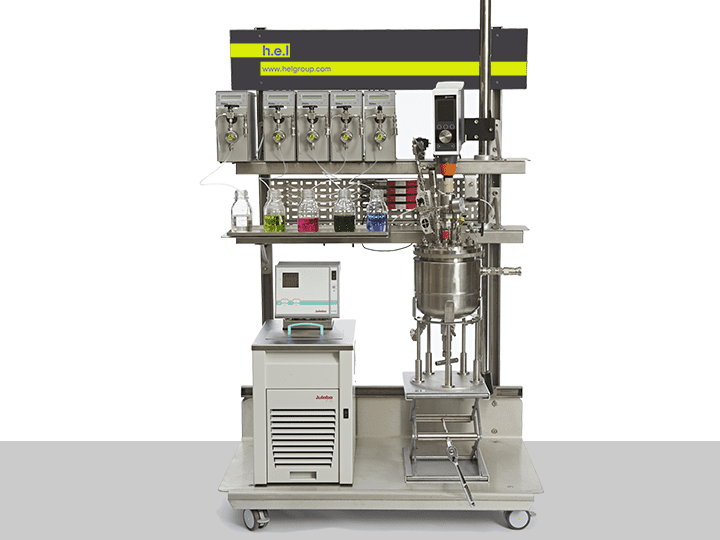

BioXplorer 5000 | Lab-scale bioreactor platform

The BioXplorer 5000 and 5000P single bioreactor systems are ideally suited to drive your s...

BioXplorer 400P | High-pressure bench-top, parallel 4 bioreactor platform

The BioXplorer 400P is an automated parallel pressure bioreactor system for the discovery ...

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...

What challenges does the process of scale-down face?

Recreating conditions as close to reality as possible in small reactors can be challenging due to the wide range of complex variables involved.

For instance, reproducing gradients that may occur in large-scale reactions due to the imperfect mix can be complex, as small-scale reactors are often well mixed, resulting in relatively homogeneous conditions. This links to another potential challenge faced by agitation at the time of down-scaling. Mixing and stirring in large-scale reactors often rely on the use of a large impeller, which will ensure adequate mixing, therefore ensuring appropriate mass and energy transfer rates. On the downside, these large impellers can exert shear stress on the cells, so balancing both values can prove difficult. Scale-down models, especially physical ones, can be time- and resource-consuming because of the time spent carefully controlling numerous parameters.

Additionally, the iterative nature also adds to the time and cost involved. However, one of the biggest challenges these tests can face is representing biological complexity, which is very difficult to capture into a scale-down model due to the highly variable nature of biological systems. Apart from biological complexity, the temporal complexity of the system can also be challenging to reproduce due to the often transient conditions changes.

Solutions

BioXplorers can play a fundamental role in scale-down process analysis. Using H.E.L’s WinISO, BioXplorer 100 and 400 can be finely controlled to replicate the conditions found at a larger scale accurately. Multiple reactors can be used to increase the throughput of the process, positioning them as a potent tool for statistical scale-down processes. On the other hand, larger reactors, such as BioXplorer 5000, can be used to replicate complex conditions, such as physicochemical gradients, and therefore can be instrumental in physical scale-down processes. The application of scale-down processes using BioXplorer models results in significant time and cost reductions, underscoring their importance in efficient and economical bioprocess management.

BioXplorer 400 | bench-top, parallel 4 bioreactor platform

The BioXplorer 400 is equipped with 4 bioreactors with working volumes of up to 400 ml. It...

BioXplorer 5000 | Lab-scale bioreactor platform

The BioXplorer 5000 and 5000P single bioreactor systems are ideally suited to drive your s...

BioXplorer 400P | High-pressure bench-top, parallel 4 bioreactor platform

The BioXplorer 400P is an automated parallel pressure bioreactor system for the discovery ...

BioXplorer 400XL | Expanded Bench-Top, Parallel 8 Bioreactor Platform

Featuring eight 500 ml bioreactors, the BioXplorer 400XL allows the fast optimization of c...