We’ve been doing some literature research and have found a few interesting recent (2019/2020) publications looking at battery testing. We’ve shared four of the most relevant ones here and will share a few more in the next month. Subscribe to the blog to get automatically notified when we post the other interesting articles we’ve found.

To help out, we’ve prepared a short summary of each publication and included a link to the original article.

Contents

1. Effects of Overdischarge Rate on Thermal Runaway of NCM811 Li-Ion Batteries

2. Thermal Runaway of a Li-Ion Battery Studied by Combined ARC and Multi-Length Scale X-ray CT

3. Deciphering the Interface of a High‐Voltage (5 V‐Class) Li‐Ion Battery Containing Additive‐Assisted Sulfolane‐Based Electrolyte

4. Prediction of the heavy charging current effect on nickel-rich/silicon-graphite power batteries based on adiabatic rate calorimetry measurement

1. Wang, L. Zheng, X. Li, G. Du, Z. Zhang, Y. Feng, L. Jia and Z. Dai, Energies, 2020, 13, 3885.

Effects of Overdischarge Rate on Thermal Runaway of NCM811 Li-Ion Batteries

(Open access article)

This paper investigates the over-discharge behaviour of 2.9 Ah cylindrical NCM811 [Li(Ni0.8 Co0.1Mn0.1)O2] batteries in an adiabatic environment. The BTC-130 was used for adiabatic reaction testing on the battery, from this, it was found that:

– As over-discharge rate increased, the battery self-heat rate also increased

– The total energy released from an external short circuit increased with the over-discharge rate

– The safe over-discharge rate was reduced at temperatures above 55 °C

– Shallow over-discharging to 2 V and 1 V had a negligible effect on the capacity of the battery

– This was because over-discharging damaged the graphite negative-electrode structure

– The samples could not recover after over-discharging, however no fires, explosions or thermal runaway occurred

The review therefore concludes that the NCM811 battery is safe under mild over-discharging conditions.

2. Patel, J. Robinson, S. Ball, D. Brett and P. Shearing, J. Electrochem. Soc., 2020, 167, 090511.

Thermal Runaway of a Li-Ion Battery Studied by Combined ARC and Multi-Length Scale X-ray CT

(Open access article)

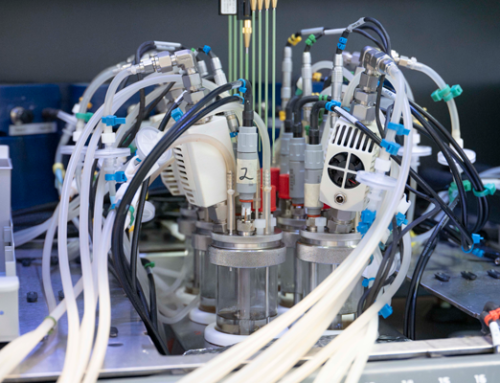

This paper investigates the properties of thermal failure and its effects on electrode materials, in an 18650 format commercial Li-ion battery, using Accelerating rate calorimetry (ARC) and multi-length scale X-ray computed tomography (CT). The BTC is used to measure, under adiabatic conditions, the heat dissipated from the cell during thermal runaway and enables the identification of key thermal failure characteristics, such as onset temperatures and the rate of heat generation during the failure. Mechanical deformations from this thermal runaway were then identified by X-ray CT and scanning electron microscopy (SEM). The paper concludes that solid electrolyte interface (SEI) layer breakdown occurs at 30-50 °C but then reforms, and the onset temperature for thermal decomposition is 175 °C. Melting of the shutdown separator was found to delay the time taken to reach the onset temperature significantly. It is also stated that X-ray CT imaging is a strong diagnostic tool for deciphering the series of events that a Li-ion battery undergoes during failure.

3. D.Lu, G. Xu, Z. Hu, Z. Cui, X. Wang, J. Li, L. Huang, X. Du, Y. Wang, J. Ma, X. Lu, H. Lin, C. Chen, A. Nugroho, L. Tjeng and G. Cui, Small Methods, 2019, 3, 1900546.

Deciphering the Interface of a High‐Voltage (5 V‐Class) Li‐Ion Battery Containing Additive‐Assisted Sulfolane‐Based Electrolyte

(Subscription or purchase required for full access)

This paper discusses a high-voltage LiNi0.4Mn1.5O4/MCMB battery system. The system uses a 1 M lithium difluoro(oxalate)borate/sulfolane, tris(trimethylsilyl) phosphite (TMSP) additive to significantly improve room- and high-temperature cycling performances. The BTC-130 was used to conduct an adiabatic analysis of the thermal stability of the battery using TMSP (5 wt%) electrolyte, compared with conventional LiPF6 electrolyte.

The TMSP was shown to have greater thermal stability, with an onset temperature of 230 °C, compared to 90 oC for LiPF6. In combination with the electrolyte’s flame retardancy, the TMSP endows superior safety characteristics. The paper provides valuable perspectives for formulating novel electrolytes, and for accurately depicting additive action mechanisms in “enigmatic” electrode/electrolyte interfacial reaction processes.

4. H. Li, C. Liu, X. Kong, J. Cheng and J. Zhao, J. Power Sources, 2019, 438, 226971.

Prediction of the heavy charging current effect on nickel-rich/silicon-graphite power batteries based on adiabatic rate calorimetry measurement

(Subscription or purchase required for full access)

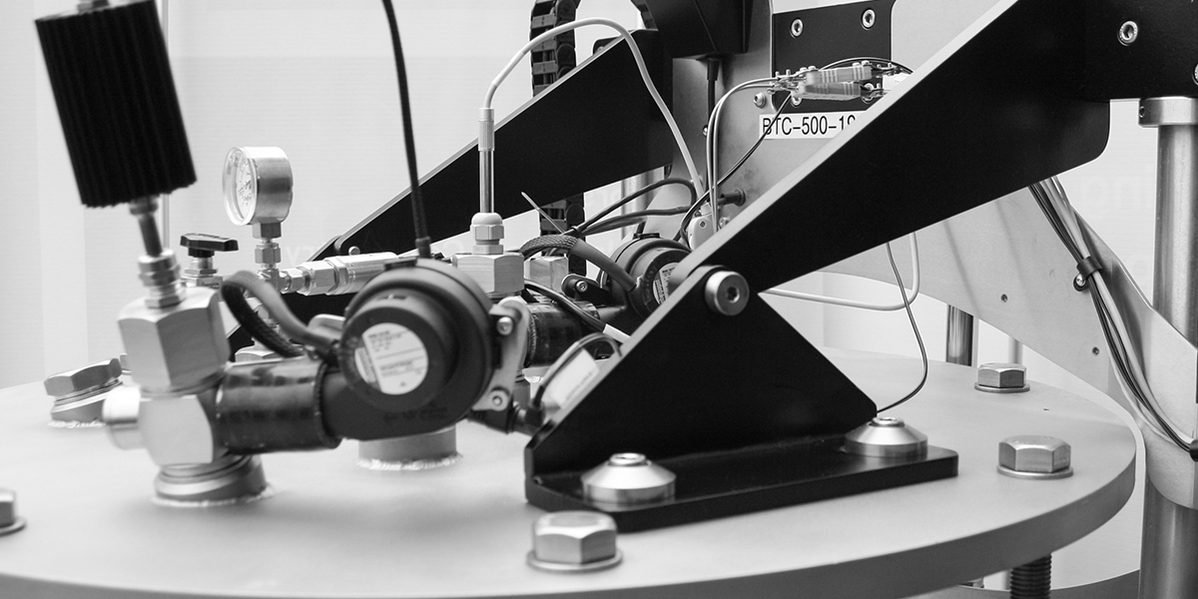

This article discusses a LiNi0.8Mn0.1Co 0.1 O2/Silicon-carbon lithium-ion battery used in plugin electric vehicles due to its high specific energy. Using the BTC-500, an adiabatic thermal analysis was undertaken to measure the battery charging process temperature at ambient conditions. The magnitude of the resulting thermal runaway was also measured.

The battery began a self-heating process at around 59.5 °C, and therefore will enter a dangerous state whenever operated over this temperature. At 150 °C, the battery temperature underwent a violent runaway. The authors conclude that the typical battery operating

- temperature should be under 59.5 °C and that their work provides guidance on the safe use, and thermal management, of the battery.

In case you didn’t yet have a chance to watch it, please take a look at our recent webinar on applications of isothermal calorimetry battery testing, which is accessible here.

Let us know in the comments below if there are any other publications we should include on the list. We’d also love to talk to you about any future work that you are planning to publish, or would like some help with – please contact us