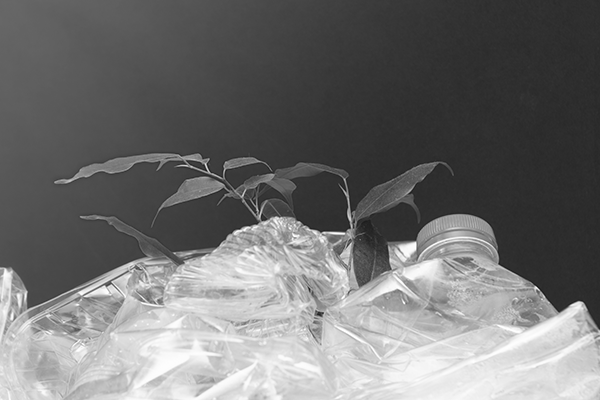

Plastics are everywhere, from bags to means of transport. They are a pervasive element in our lives, and that is one of the main issues. To meet the market needs, over 460 million metric tons of plastics are generated every year, and it is expected that this number will double before 20501,2. Plastics were conceived to be recalcitrant, which means they are difficult to degrade, and consequently, they build up over time. This accumulation is highly polluting and harmful to the environment. However, despite their endurance, environmental factors, such as sunlight or erosion, can fragment plastics, resulting in microplastic and nanoplastics that can accumulate within living organisms. Single-use products, such as bottles, caps, shopping bags, cups, and straws, generate much plastic pollution.

Traditional plastics are synthesized from fossil fuels, such as petroleum and oil. Since the advent of synthetic plastics, starting with bakelite in the 1900s, chemical synthesis has provided us with a wide range suitable for many applications. However, the overreliance on non-renewable resources means that by 2050, greenhouse gas emissions linked to plastic production will amount to 15% of the carbon budget. As such, the United Nations Environment Programme has prioritized reducing CO2 emissions linked to these chemical products.

The ever-growing need for plastics requires the continuous production of these materials to meet the market demands. However, especially single-use plastics become a problem. Not only do they require fossil fuels for their chemical synthesis, but it is also a highly energy-consuming process. Recycling is a great alternative for plastics, reducing greenhouse gas emissions and avoiding the release of nutrients such as nitrogen (N) and phosphorus (P). The uncontrolled discharge of nutrients can result in the over-proliferation of photosynthetic organisms, such as cyanobacteria and algae, with devastating consequences. Recycling involves mechanical recycling of plastic monomers and chemical recycling, using pyrolysis for plastics containing contaminants that make them unsuitable for mechanical recycling. Nevertheless, due to the nature of the process, material loss is unavoidable, requiring the production of new plastics.3

Are plant-based plastics the solution to all our problems?

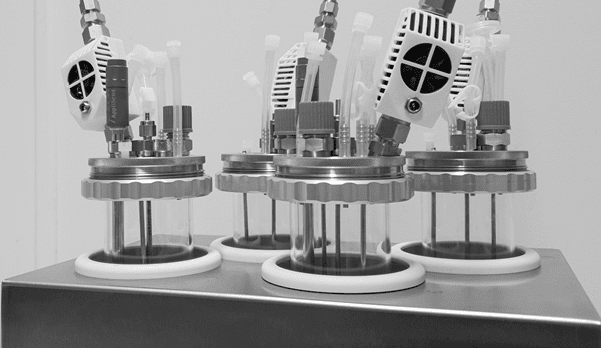

Plastics are synthetic polymers, so chemical reactions are required to combine monomers into the desired product. One of the central molecules that act as the precursor for the monomers is methanol. Several means can produce this very simple yet versatile chemical. For example, gas waste from industry can be reformed to produce carbon monoxide and carbon dioxide, which can be combined with hydrogen, resulting in methanol. Another option involves the hydrolysis of the water molecule, producing O2 and H2. The hydrogen can react with CO2, producing methanol. However, methanol can also be obtained from biomass. This very abundant source must be transformed by gasification or combustion to produce the precursors and then react with hydrogen. However, extensive use of land for biomass production for this process significantly worsens the biosphere’s integrity. Additionally, vegetation requires certain nutrients, such as nitrogen, which is known to be a pollutant, especially in environments susceptible to runoff.

Plastics are synthetic polymers, so chemical reactions are required to combine monomers into the desired product. One of the central molecules that act as the precursor for the monomers is methanol. Several means can produce this very simple yet versatile chemical. For example, gas waste from industry can be reformed to produce carbon monoxide and carbon dioxide, which can be combined with hydrogen, resulting in methanol. Another option involves the hydrolysis of the water molecule, producing O2 and H2. The hydrogen can react with CO2, producing methanol. However, methanol can also be obtained from biomass. This very abundant source must be transformed by gasification or combustion to produce the precursors and then react with hydrogen. However, extensive use of land for biomass production for this process significantly worsens the biosphere’s integrity. Additionally, vegetation requires certain nutrients, such as nitrogen, which is known to be a pollutant, especially in environments susceptible to runoff.

Despite their potential for reducing greenhouse gas emissions, plant-based plastics are not the solution to all problems. According to a study published in Natural Sustainability, it is fundamental to integrate bio-derived plastics with existing recycling strategies to help mitigate climate change. However, the shift requires balancing greenhouse gas emissions, biogeochemical flows, and biosphere integrity. For instance, the extensive cultivation of biomass for plastic production can disrupt ecosystems and deplete essential nutrients from the soil, leading to nitrogen pollution and other adverse effects on local environments. Moreover, the high demand for land to grow biomass can result in habitat loss and a decline in biodiversity.

Chemical synthesis aiding climate change

Methanol is a key player in the production of plastics, but it is not the only molecule involved. For example, several studies have shown that CO2 can be used in the processes of copolymerization4,5. This requires the presence of two or more monomers to produce the final polymer. This gas is a cheap alternative that helps remove it from the atmosphere and lock it into plastics, helping to address global warming.

On top of that, recent advancements in chemistry have yielded catalysis that increases the efficiency of transforming carbon dioxide into a useful chemical. For example, β-Mo2C nanoparticle catalysts supported on SiO2 have shown promising results in converting CO2 to carbon monoxide. Furthermore, the synthesis of fuel-grade dimethyl ether (DME) from CO2 and green hydrogen is being explored as a viable alternative to fossil fuels. Although currently more expensive than conventional methods, this process holds promise for reducing carbon emissions and providing a sustainable energy source.

On top of that, recent advancements in chemistry have yielded catalysis that increases the efficiency of transforming carbon dioxide into a useful chemical. For example, β-Mo2C nanoparticle catalysts supported on SiO2 have shown promising results in converting CO2 to carbon monoxide. Furthermore, the synthesis of fuel-grade dimethyl ether (DME) from CO2 and green hydrogen is being explored as a viable alternative to fossil fuels. Although currently more expensive than conventional methods, this process holds promise for reducing carbon emissions and providing a sustainable energy source.

In conclusion, while plant-based plastics are a promising alternative to traditional plastics, helping us reduce our reliance on fossil fuels and addressing some aspects of climate change, they are not a magic solution. The production of these bioplastics must be carefully controlled to avoid exacerbating other environmental issues. Integrating advanced recycling techniques and exploring innovative chemical synthesis methods are crucial to a more sustainable future.

References

1. Agenda, I. The new plastics economy rethinking the future of plastics. in World Economic Forum vol. 36 (2016).

2. Co-operation, O. for E. & Development. Global Plastics Outlook: Economic Drivers, Environmental Impacts and Policy Options. (OECD Publishing, 2022).

3. Bachmann, M. et al. Towards circular plastics within planetary boundaries. Nat. Sustain. 6, 599–610 (2023).

4. Garcia Espinosa, L. D., Williams-Pavlantos, K., Turney, K. M., Wesdemiotis, C. & Eagan, J. M. Degradable polymer structures from carbon dioxide and butadiene. ACS Macro Lett. 10, 1254–1259 (2021).

5. Tang, S. et al. Sustainable Copolymer Synthesis from Carbon Dioxide and Butadiene. Chem. Rev. 124, 3590–3607 (2024).