Customizable solutions for process safety and battery development

Maximize your operations’ potential with our customizable solutions for process safety and battery development. Combining advanced technology with industry-leading expertise, we create tailored solutions that make your processes safe, efficient, and future-ready. Whether pioneering new battery technology or improving industrial safety, our innovative approach adapts to your specific needs, driving progress and ensuring your success. Let us help you turn challenges into opportunities for growth and innovation.

Select your perfect process safety and battery testing solutions from our compatible options, all with advanced technology to maximize operational potential.

(1) Choose your process safety solution

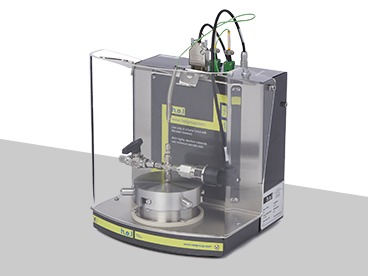

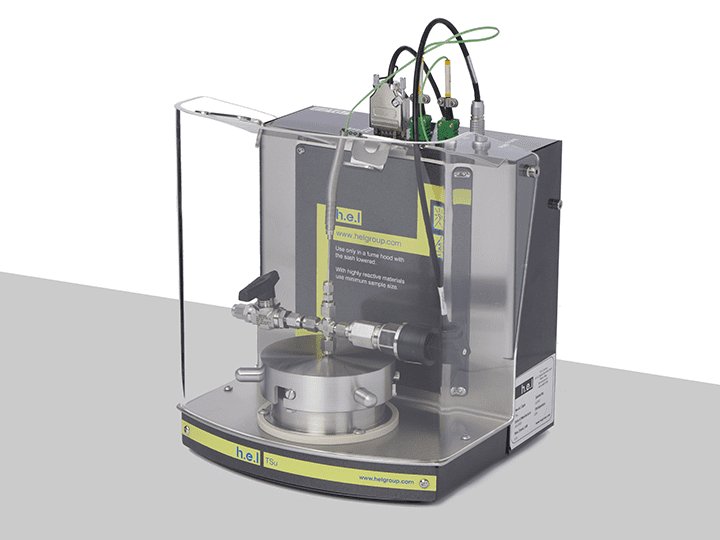

This compact thermal screening unit is designed to monitor the thermal evolution of reactants and products. It enables scientists and engineers to determine the thermal stability of the cell components. Using its capabilities, critical parameters, such as the onset temperature (Td) of the exotherm and the pressure generated by the resultant runaway, can be easily monitored.

Features:

Ideal for chemical process discovery and component analysis in the cell development phase

- Compact systems with minimal footprint

- Temperature and pressure tracking to detect thermal runaway events

- Range of test cells, available in glass, stainless steel, and Hastelloy

Expandable options:

The small footprint of TSu makes it easy to fit several units into a standard fume hood, being operated using the same software, increasing the throughput capabilities.

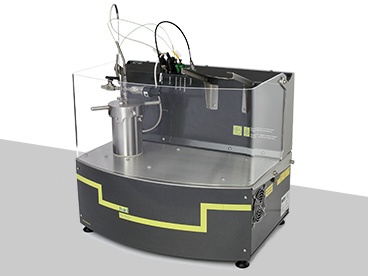

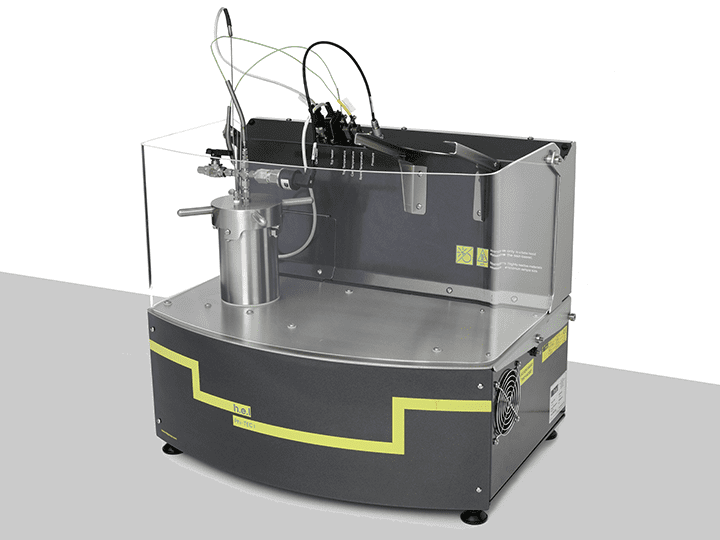

Our adiabatic calorimeters using high phi-factor (Phi-TEC I) and low phi-factor (Phi-TEC II) test cells are designed to characterize thermal runaway hazards. The adiabatic screening characterizes thermal events, including critical parameters, such as onset temperature (Td). This information is crucial to calculate safety parameters, such as adiabatic temperature rise (∆Tad,d) and time to maximum rate (TMRd). Phi-TEC II, using low phi-factor cells, allows for the calculation of extra parameters, like controlled depressurization and vent sizing.

Features:

Phi-TEC I is ideal for raw material and cell component hazard screening in the discovery phase, whereas both Phi-TEC I and II excel in the scale-up phase.

- Phi-TEC I uses high phi-factor cells in glass, stainless steel and Hastelloy with volumes between 0.5-10 ml. Phi-TEC II is also compatible with either thin-walled low phi-factor cells.

- Temperature of up 500 °C

- Pressure from 1 to 137 (Phi-TEC II) or 200 bar (Phi-TEC I)

- Stirring at 300 rpm

- Controlled by software for data logging, multi-step recipes, parameter control, and feedback loops

- Safety features, automatic and user-configurable, with shutdown procedures for both hardware and software

Expandable options:

- Safety release valve

- Gas sampling

- High-pressure pumps and injector

- High data rate acquisitions (up for 10000 Hz)

(2) Choose the battery performance solution(s) for you

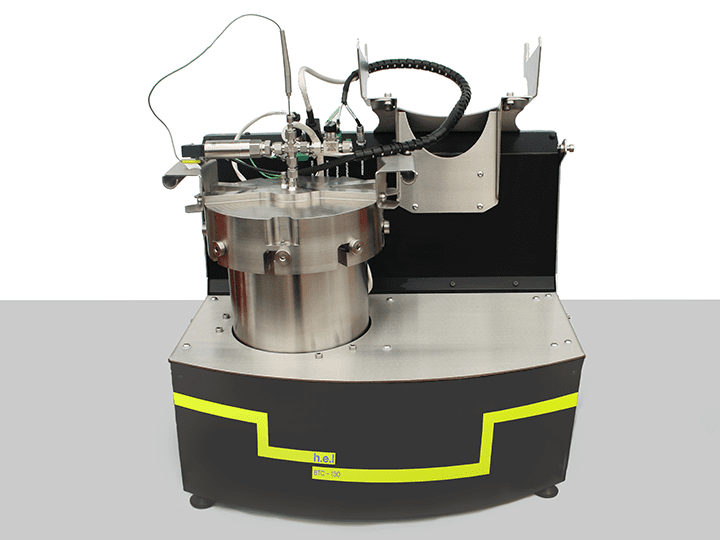

BTC-130 is a bench-scale adiabatic calorimeter designed to enable the testing of thermal, electrical, and mechanical stress on small-size batteries and individual battery cells. This type of test is fundamental to determining their safety performance, the operational limits, and identification of the mechanism by which the thermal runaways occur. BTC-130 is compatible with small-volume spherical test cells, allowing for screening of individual components.

Features:

- Allows for three types of test, thermal (overheating), electrical (overcharging and discharging), mechanical stress (nail puncture)

- It supports the testing of cells components, coin cells, small pouch cells, and cylindrical cells

- Temperature up to 500 °C

- Safety features, automatic and user-configurable, with shutdown procedures, for both hardware and software

Expandable options:

- Compatible with spherical test cells

- High data rate acquisitions (up for 10000 Hz)

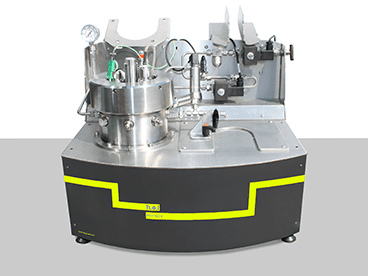

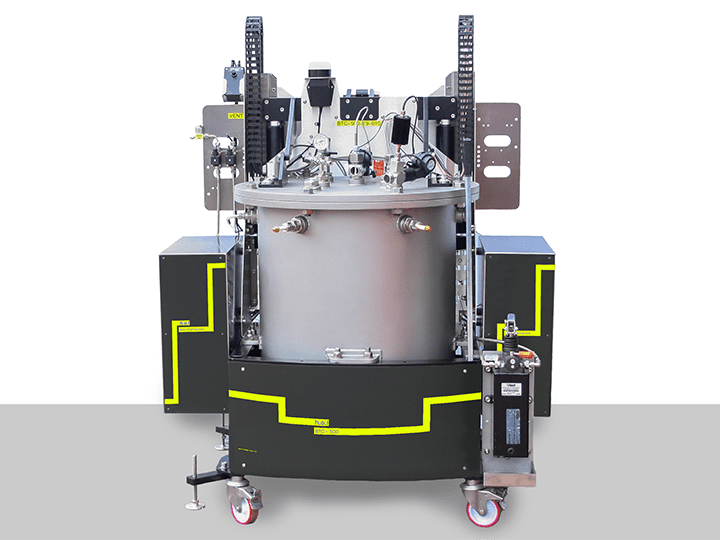

BTC-500 is a floor-standing adiabatic calorimeter designed for the safe testing of larger batteries and small modules. This testing includes thermal, electrical, and mechanical stress, allowing the determination of operation limits and the characterization of thermal runaway events and their propagation. This enables the assessment of the safety performance of storage devices.

Features:

Ideal for proof-of-concept experiments prior to manufacturing

- Allows for three types of test, thermal (overheating), electrical (overcharging and discharging), mechanical stress (nail puncture)

- Allows for the testing of cylindrical, prismatic, pouch cells, and small modules

- Temperature up to 500 °C

- Safety features, automatic and user-configurable, with shutdown procedures, for both hardware and software

Expandable options:

-

Sub-ambient temperature up to -40°C

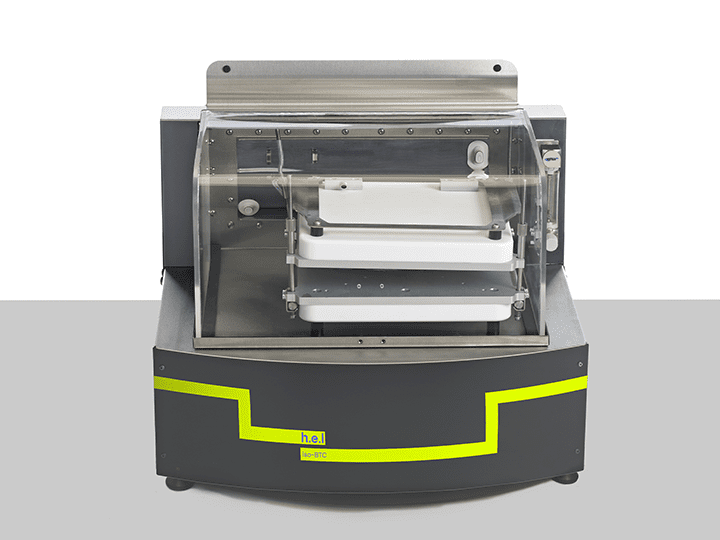

The iso-BTC is an isothermal calorimeter designed specifically for the characterization of the thermal behavior and the performance analysis of cells and small-size batteries in both normal and extended conditions. The automation of the charge-discharge cycles enables testing under a range of conditions, as well as accelerated aging tests. Multipoint temperature measurement allows the identification of hot spots in the battery. This information can be used to developed targeted thermal managed strategies.

Features:

- Testing for performance under normal and abnormal use, as well as aging.

- Battery adaptor allows for the testing of cylindrical cells, pouch, and small prismatic cells

- Testing temperature from -20°C to 90°C

- Safety features include automatic event detection and shutdown procedures, multi-point sample temperature measurement, and automated hardware and software fail-safes

- Controlled by software for data logging, multi-step recipes, parameter control, and feedback loops

Expandable options:

-

Sub-ambient temperature up to -40°C

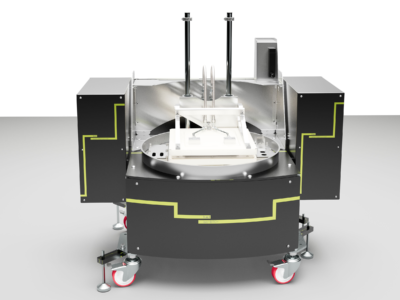

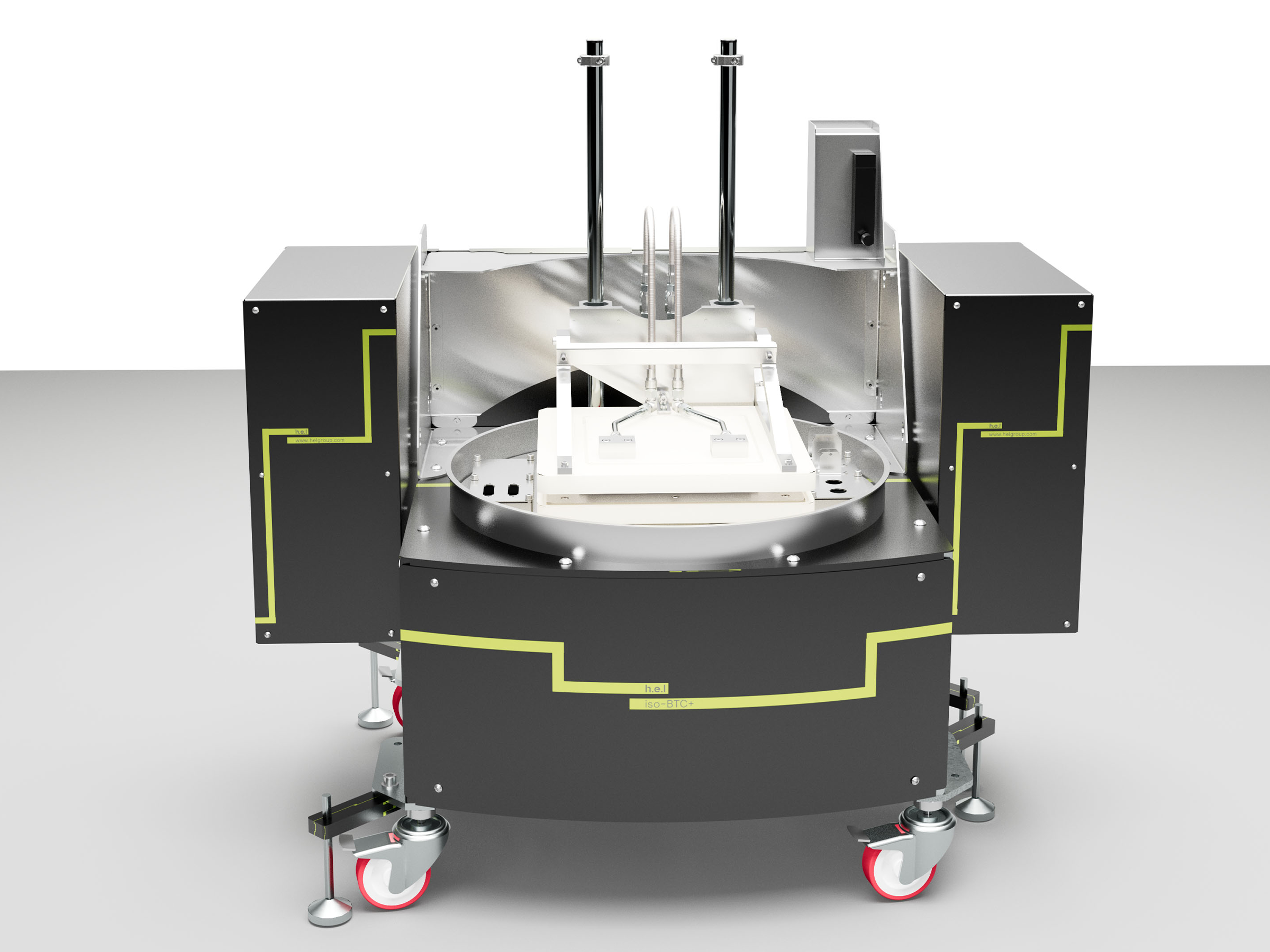

The iso-BTC + is a floor-standing isothermal calorimeter designed to determine battery heat-release profiles as well as environment temperature effects for the design of thermal management systems. It can also help to understand the performance consequences of use, misuse, and battery aging. It enables the test of higher power and physically larger batteries. The data obtained can help to build safer and higher-performing batteries. A deeper understanding of the batteries can help to simulate thermal propagation, resulting in time-saving during battery and product testing.

Features:

- Performance testing for normal and abnormal use, and aging and performance testing

- Battery behavior, allowing for the characterization of heat release profiles, battery efficiency profiles, and charge/discharge capacity

- Testing of cylindrical, prismatic, and pouch cells

- 200 W maximum measured power

- Temperature ranges from -20°C to 90°C

- Safety features include automatic event detection and shutdown procedures, multi-point sample temperature measurement, and automate hardware and software fail-safes

Expandable options:

-

Sub-ambient temperature up to -40°C

Speak to one of our specialists today to find out more!

Having confidence that new equipment will meet your needs is so important. That’s why H.E.L works closely with clients to create individual solutions that are a perfect fit for them, their location and budget.

That continues as needs change over time. Whether for system upgrades, training new recruits or process support, our dedicated teams and knowledgeable staff are here for you. Contact them any time.

Equipment tailored to your needs

H.E.L has a well-established history of creating customized, automated solutions for battery development and process safety. Discover more about our built-in features and expandable options designed to enhance your operations and safety protocols.