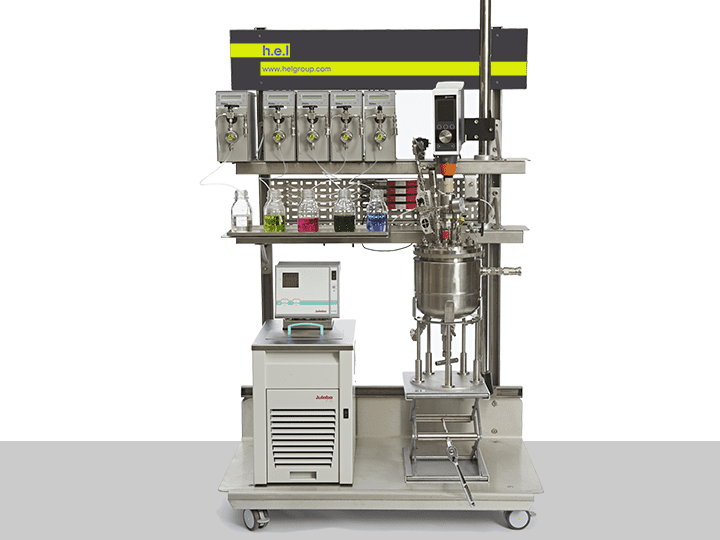

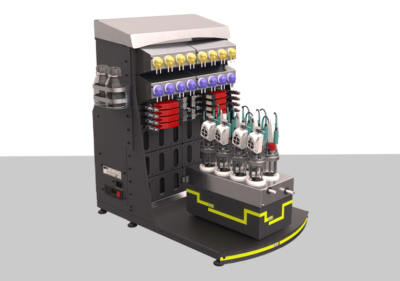

BioXplorer 5000 | Lab-scale bioreactor platform

The BioXplorer 5000 and 5000P single bioreactor systems are ideally suited to drive your scale-up efficiency. These systems are highly automated and highly customizable. The BioXplorer 5000P is the ideal choice for pressure applications up to 10 bar, ranging from syngas fermentation to processes driven by cell-free biocatalysis.

Download BioXplorer 5000 brochureFeatures

The BioXplorer 5000 and 5000P single bioreactor systems are suitable for a wide range of applications including syngas fermentation and cell-free biocatalysis with:

- Automated inventory monitoring

- BioVIS optical probe to monitor cell density trends without taking samples

- Choice of reactor sizes and types, including elevated pressure designs (up to 10 bar)

- Fully automated control

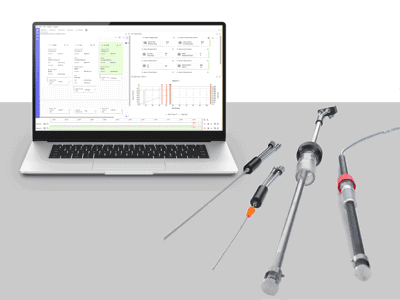

Software

The H.E.L control software runs the BioXplorer 5000 system, enabling complex, fully automated experiments to run unattended.

This enables:

- Full reactor control with unlimited step recipe planning. Plans can be changed online at any time without process interruption

- The individual reactor temperature and agitation control

- User-defined data-logging with customizable tabular and graphical displays

- Export data functions and integration with in-house electronic lab notebooks and record-keeping systems

- DoE and QbD package integration

More specifically, the software controls a wide range of system features, including:

- Temperature

- Gas feeds, flow and mix

- pH

- Dissolved oxygen

- Redox

- Stirrer speed

- Torque (for viscosity indication)

- Pressure

- Liquid feed rates

- Antifoam and level detection

Technical Literature

The following is a list of supporting Technical Literature.

The use of a H.E.L BioXplorer in fermentations of Cupriavidus necator H16 at elevated pressure using CO2 as the sole carbon source

Publications

The following are a list of some technical publications which highlight the use of the equipment.

Innovative high pressure/high temperature, multi-sensing bioreactors system for microbial risk assessment in underground hydrogen storage

Nicolò Santi Vasile, Ruggero Bellini, Ilaria Bassani, Arianna Vizzarro, Annalisa Abdel Azim, Christian Coti, Donatella Barbieri, Matteo Scapolo, Dario Viberti, Francesca Verga, Fabrizio Pirri, Barbara Menin

02-Jan-2024

https://www.sciencedirect.com/science/article/pii/S0360319923053934(Subscription or purchase maybe required for full access)

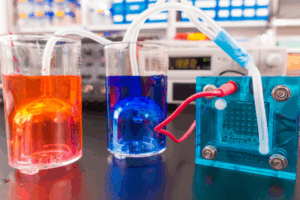

Isobutanol production freed from biological limits using synthetic biochemistry

S. Sherkhanov, T.P. Korman, S.Chan, S. Faham, H. Liu, M.R. Sawaya, WT. Hsu, E. Vikram, T. Cheng, J.U. Bowie

01-Dec-2020

https://doi.org/10.1038/s41467-020-18124-1(Subscription or purchase maybe required for full access)

Downloads

The following are a list of available downloads.

Industries and Applications

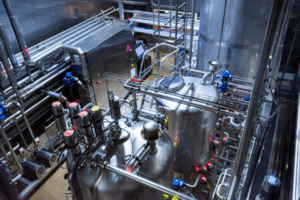

Fermentation for Sustainable Aviation Fuel (SAF)

Advance sustainable aviation fuel R&D with fermentation systems designed for CO₂, H₂, and CO gas…

CO₂-Based Biomanufacturing Platforms

Develop carbon-negative fermentation processes using CO₂ as the primary feedstock in microbial bioproduction of fuels,…

Renewable PtL Systems

Simulate Power-to-Liquid (PtL) processes for converting renewable electricity and captured carbon dioxide into liquid fuels…

Syngas Fermentation for Bioethanol Production

Optimize syngas-to-ethanol microbial conversion using precise control of gas composition, flow rates, and fermentation parameters.

Industrial Waste Gas Fermentation

Capture and integrate industrial CO, CO₂, and syngas emissions using scalable gas fermentation systems for…

Parallel Bioreactors for Gas Fermentation

Boost gas substrate availability and reduce costs in your production of biofuel & SAF.