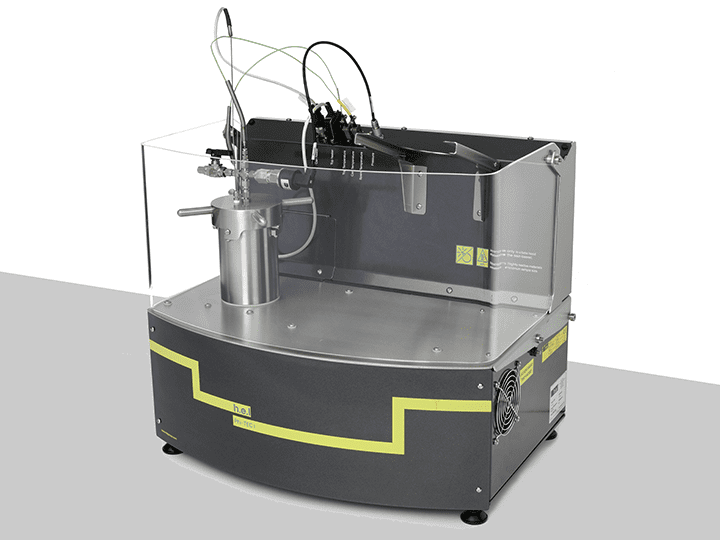

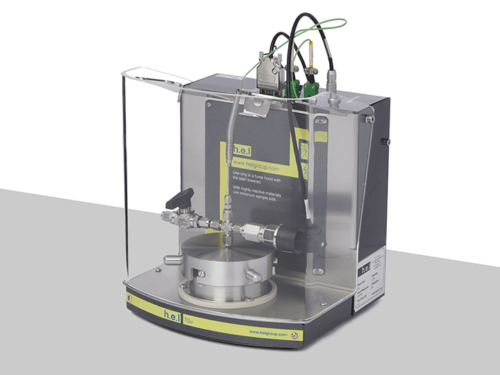

Phi-TEC I | Bench-top, high phi-factor, adiabatic calorimeter

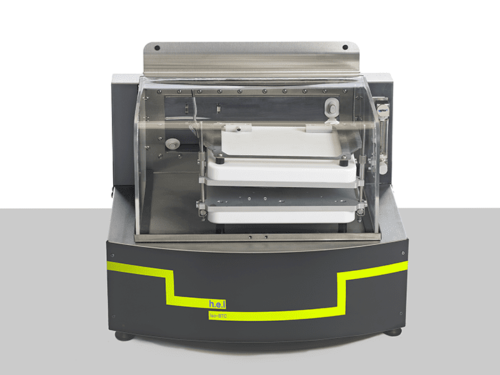

The Phi-TEC I is an adiabatic calorimeter that enables the characterization of thermal runaway hazards during process development and scale-up. The Phi-TEC I replicates industrial (large volume) conditions on a lab-scale, enabling thermal runaway hazards to be characterized safely and efficiently.

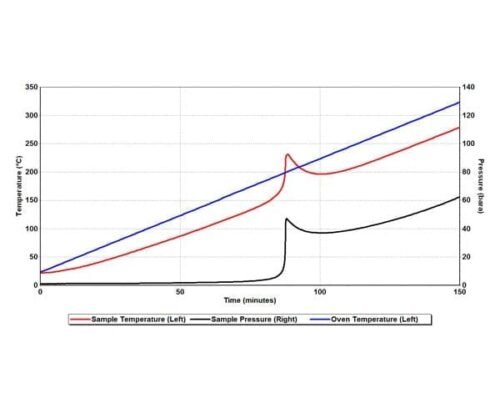

Via direct sample temperature measurement and by rapidly responding to any thermal changes, the Phi-TEC I accurately tracks exothermic events and maintains adiabatic conditions. This adiabatic screening enables thermal events to be defined with the accurate characterization of the onset temperature (Td) and facilitates the calculation of other key parameters, such as the rate of pressure change, the adiabatic temperature rise (∆Tad,d), and the time to maximum rate (TMRd).

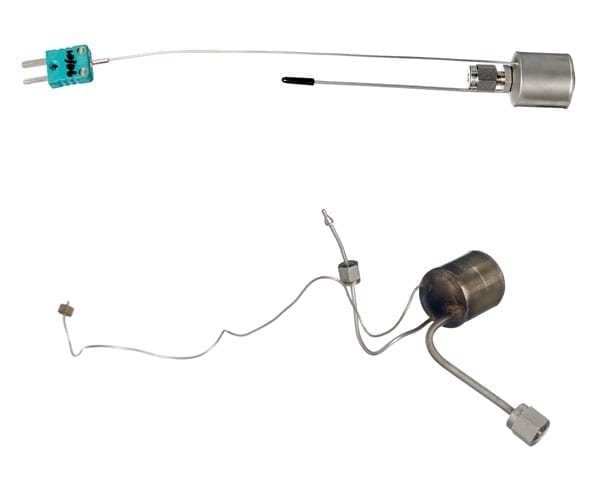

High Phi-Factor Test Cell Catalog

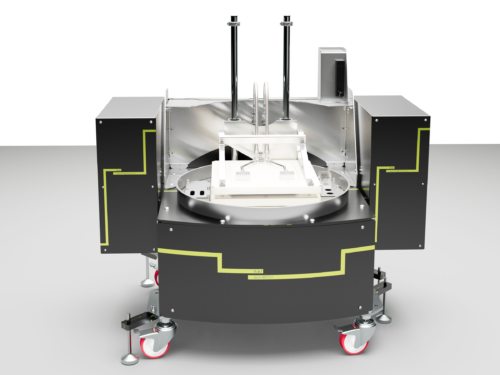

Process Safety and Scale Up Specifications

Applications

Rapid reactions

If there is a need to characterize especially rapid decompositions, the Phi-TEC I offers a high data-rate acquisition option, which provides higher resolution data on the rate of pressure and temperature changes. When scaling up a process, accurate knowledge of an exothermic event is vital to ensure the magnitude of the thermal runaway risk is fully understood.

Adiabatic calorimetry

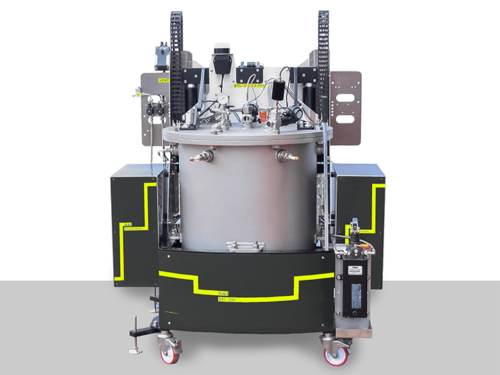

Large scale reactors lose very little of the heat generated in a reaction to the surroundings. This poses a potential hazard when operating at large scale, as that heat will be retained within the reactor. At best this will require plant cooling and at worst may trigger a thermal runaway.

The Phi-TEC I mimics the processes at large scale, while operating at laboratory volumes.

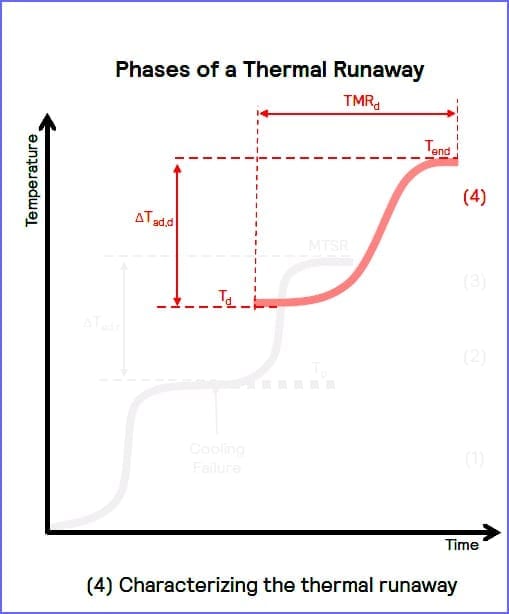

Characterizing the thermal runaway (4)

Providing a direct measurement of the sample temperature, coupled with a rapid response to thermal changes, the Phi-TEC I accurately tracks exothermic events and maintains adiabatic conditions.

Providing a direct measurement of the sample temperature, coupled with a rapid response to thermal changes, the Phi-TEC I accurately tracks exothermic events and maintains adiabatic conditions.

Adiabatic screening of a process enables accurate characterization of the onset temperature (Td) and facilitates calculation of the time to maximum rate (TMRd), the adiabatic temperature rise (ΔTad,d) and the rate of pressure change. These key parameters can help describe the magnitude of the thermal runaway hazard.

Technical Literature

The following is a list of supporting Technical Literature.

Publications

The following are a list of some technical publications which highlight the use of the equipment.

Effects of metal ions on thermal hazard of tert-butyl peroxy-3, 5, 5-trimethylhexanoate

Xiang-Hui Shi, Yong Pana, Xin Zhang, Yan-Jun Wang, Li Xia, Jun-Cheng Jiang and Chi-Min Shu

01-Feb-2023

https://www.sciencedirect.com/science/article/abs/pii/S0950423023000037(Subscription or purchase maybe required for full access)

Evaluation of the thermal runaway decomposition of cumene hydroperoxide by adiabatic calorimetry

OJ Reyes-Valdes, VC Moreno & M Sam-Mannan

01-Jan-2023

https://www.researchgate.net/profile/Olga-Reyes-Valdes/publication/298643716_Evaluation_of_the_Thermal_Runaway_Decomposition_of_Cumene_Hydroperoxide_by_Adiabatic_Calorimetry/links/571660a008ae497c1a56feb3/Evaluation-of-the-Thermal-Runaway-Decomposition-of-Cumene-Hydroperoxide-by-Adiabatic-Calorimetry.pdf(Subscription or purchase maybe required for full access)

Effect of reaction type on TMRad, TD24 and other data obtained by adiabatic calorimetry

Xiao-juan Wu, Yi Zhu, Li-ping Chen, Wang-hua Chen & Zi-chao Guo

26-Jun-2021

https://link.springer.com/article/10.1007/s10973-021-10787-2(Subscription or purchase maybe required for full access)

Research on Thermal Decomposition Kinetics and Thermal Safety for a New Epoxiconazole Crystal

Zhen-Yun Wei, Ji-Shuang Tan, Xiao-Hua Ma, Rong Kong, Xuan Liu, Chun-Sheng Cheng & San-Xi Li

16-Feb-2021

https://pubs.acs.org/doi/full/10.1021/acsomega.0c05988(Subscription or purchase maybe required for full access)

Determination of SADT and TMRad of 3-bromo-1-(3,5-dichloropyridin-2-yl)-4,5-dihydro-1H-pyrazole-5-carboxylic acid: Applying thermal decomposition kinetics

Yun-Bo Cong, Zhen-Yun Wei, Xiao-Hua Ma, Zi-Liang Li, Quan-Guo Li, Xu Ming & Chun-Sheng Cheng

31-Jan-2021

https://www.sciencedirect.com/science/article/pii/S2211715621000175(Subscription or purchase maybe required for full access)

Continuous Safety Improvements to Avoid Runaway Reactions: The Case of a Chloro-Thiadiazole Intermediate Synthesis toward Timolol

Alessandro Agosti, Silvia Panzeri, Federico Gassa, Massimo Magnani, Giulia Forni, Marco Quaroni, Lazzaro Feliciani and Giorgio Bertolini

19-May-2020

https://doi.org/10.1021/acs.oprd.0c00048(Subscription or purchase maybe required for full access)

A kinetic-based approach in accelerating rate calorimetry with the varying thermal inertia consideration

Jiong Ding, Liming Yu, Xiaona Wang, Qiyue Xu, Suijun Yang, Shuliang Ye & Juncheng Jiang

25-Nov-2019

https://link.springer.com/article/10.1007/s10973-019-09081-z(Subscription or purchase maybe required for full access)

Thermal hazard assessment of tris(2-methyl butyl) phosphate: A comparison with tri-n-butyl phosphate and tri-n-amyl phosphate

Subramee Sarkar, K. Chandran, M. Lavanya, N. Ramanathan, P.C. Clinsha, A. Suresh & N. Sivaraman

01-Jan-2019

https://www.sciencedirect.com/science/article/abs/pii/S0040603118304441(Subscription or purchase maybe required for full access)

An Alternative Scalable Process for the Synthesis of 4,6-Dichloropyrimidine-5-carbonitrile

Bin Zhang, Huixin Yan, Chongfeng Ge, Bo Liu and Zhenping Wu

01-Nov-2018

https://doi.org/10.1021/acs.oprd.8b00154(Subscription or purchase maybe required for full access)

Thermal decomposition behaviour of irradiated tri n-butyl phosphate and mixture of di and mono n-butyl phosphate-nitric acid systems

K. Chandran, B. Sreenivasulu, N. Ramanathan, P.C. Clinsha, A. Suresh, N. Sivaraman

10-Nov-2017

https://www.sciencedirect.com/science/article/abs/pii/S0040603117302393(Subscription or purchase maybe required for full access)

Studies on thermal decomposition behaviour of N,N-dialkyl octanamides

K. Chandran, C.V.S.Brahmmananda Rao, N. Ramanathan, N. Sivaraman & S. Anthonysamy

10-Jun-2016

https://www.sciencedirect.com/science/article/abs/pii/S0040603116300673(Subscription or purchase maybe required for full access)

Effect of gamma irradiation on thermal decomposition of tri-iso-amyl phosphate–nitric acid biphasic systems

B. Sreenivasulu, K. Chandran, P. C. Clinsha, A. Suresh, N. Sivaraman & S. Anthonysamy

17-Mar-2016

https://link.springer.com/article/10.1007/s10973-016-5375-0(Subscription or purchase maybe required for full access)

Experimental sensitivity analysis of the runaway severity of Dicumyl peroxide decomposition using adiabatic calorimetry

Olga J. Reyes Valdesa, Valeria Casson Moreno, Simon P. Waldram, Luc N. Véchot, M. Sam Mannan

10-Oct-2015

https://doi.org/10.1016/j.tca.2015.07.016(Subscription or purchase maybe required for full access)

Mathematical methods for application of experimental adiabatic data – An update and extension

Arcady A. Kossoy, Jasbir Singh, Elena Yu Koludarova

24-Nov-2014

https://www.sciencedirect.com/science/article/abs/pii/S0950423014002071(Subscription or purchase maybe required for full access)

Thermal decomposition behaviour of diglycolamide – Nitric acid system

K. Chandran, K.A. Venkatesan, S. Anthonysamy & T.G. Srinivasan

10-May-2014

https://www.sciencedirect.com/science/article/abs/pii/S0040603114000938(Subscription or purchase maybe required for full access)

Novel validation on pressure as a determination of onset point for exothermic decomposition of DTBP

Yih-Shing Duh, Wen-Fang Wang & Chen-Shan Kao

26-Feb-2014

https://link.springer.com/article/10.1007/s10973-014-3690-x(Subscription or purchase maybe required for full access)

Thermal decomposition characteristics of octyl(phenyl)-N,N-diisobutylcarbamoylmethylphosphine oxide-tri n-butyl phosphate–nitric acid systems

K. A. Venkatesan, K. Chandran, N. Ramanathan, S. Anthonysamy, V. Ganesan & T. G. Srinivasan

20-Nov-2013

https://link.springer.com/article/10.1007/s10973-013-3504-6(Subscription or purchase maybe required for full access)

Thermodynamics and kinetics of thermal decomposition of dibutylalkyl and dipentylalkyl phosphonate-nitric acid systems

K. Chandran, C.V.S. Brahmmananda Rao, S. Anthonysamy, V. Ganesan & T.G. Srinivasan

10-Oct-2013

https://www.sciencedirect.com/science/article/abs/pii/S0040603113003857(Subscription or purchase maybe required for full access)

Calorimetric studies on thermal decomposition of tri isoamyl phosphate–nitric acid systems

Tarun Kumar Sahoo, K. Chandran, P. Muralidaran, V. Ganesan & T.G. Srinivasan

20-Apr-2012

https://www.sciencedirect.com/science/article/abs/pii/S004060311200041X(Subscription or purchase maybe required for full access)

Calorimetric studies on the thermal decomposition of tri n-butyl phosphate-nitric acid systems

K. Chandran, Tarun Kumar Sahoo, P. Muralidara, V. Ganesan & T. G. Srinivasan

14-Oct-2011

https://akjournals.com/view/journals/10973/110/2/article-p879.xml(Subscription or purchase maybe required for full access)

Downloads

The following are a list of available downloads.

High Phi-Factor Test Cell Catalog

Process Safety and Scale Up Specifications