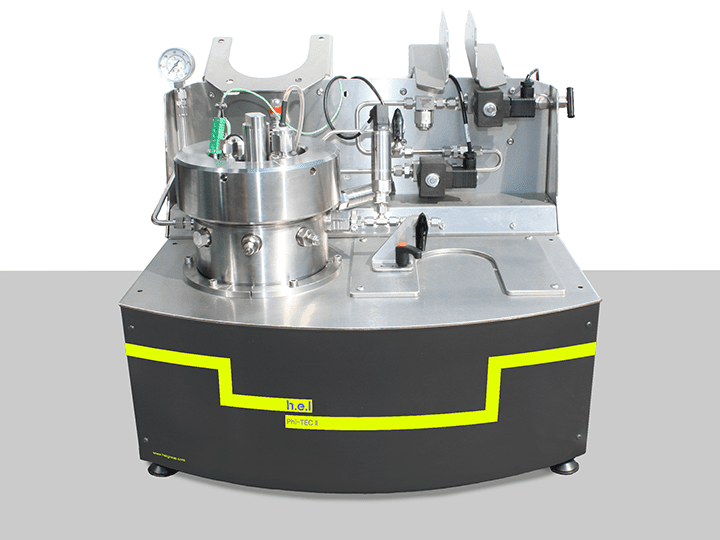

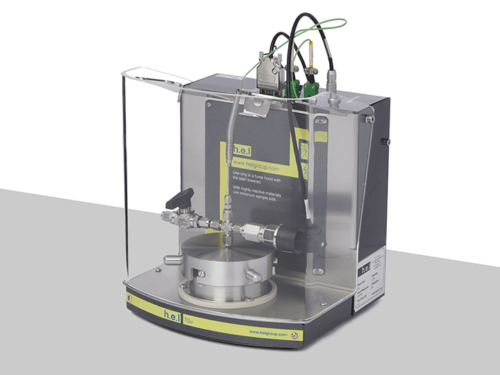

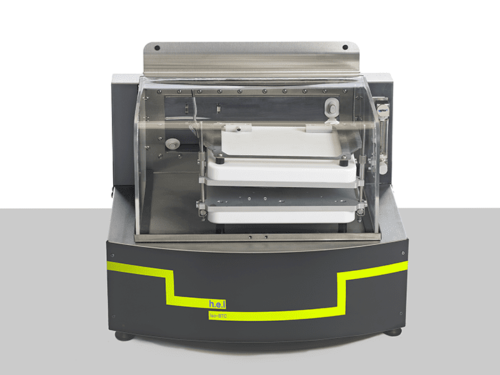

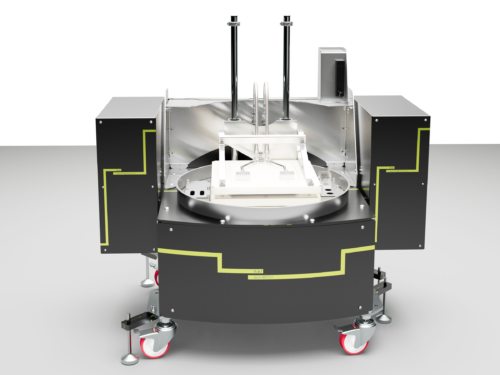

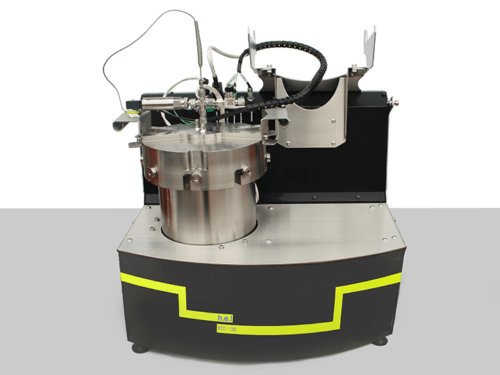

Phi-TEC II | Bench-top, low phi-factor, adiabatic calorimeter

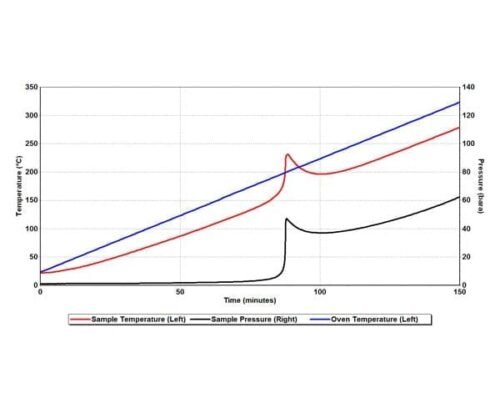

The Phi-TEC II is an adiabatic calorimeter, which supports the use of low Phi-factor test cells. This allows for manufacturing plant conditions to be fully replicated on a lab-scale thus allowing thermal runaway risks to be simulated and assessed. Utilizing low-Phi factor cells means that the runaway rate is not tempered by the test equipment, and subsequently, the measured rate of pressure increase and final temperature (Tend) – along with the calculated Time to Maximum Rate (TMRd) and adiabatic temperature rise (∆Tad,d) – are representative of what would be expected to occur during a production-scale incident

The impact of different operating scenarios can be explored using the Phi-TEC II, and the data generated can be utilized to determine appropriate safety controls for the manufacturing plant, such as:

- Emergency and evaporation cooling

- Quenching

- Controlled depressurization

- Vent sizing (in accordance with DIERS methodology)

Thus, the Phi-TEC II enables hazards to be fully evaluated, enabling their mitigation prior to scale-up.

High Phi-Factor Test Cell Catalog

Process Safety and Scale Up Specifications

Applications

Hazard and Operability Assessment

Plant-scale parameters from the laboratory

The Phi-TEC II is a more advanced type of adiabatic calorimeter, which supports the use of low Phi factor test cells. This capability means that very little of the heat produced during a reaction or thermal runaway is consumed in warming the test cell. As a result, the runaway rate is not tempered.

The measured rate of pressure increase and final temperature (Tend), along with the calculated Time to Maximum Rate (TMR) and adiabatic temperature rise (ΔTad), are representative of what would be expected to occur during a manufacturing scale incident. Thus, the Phi-TEC II enables the hazards to be fully evaluated and explored, facilitating their mitigation prior to scale-up.

Safety by design

The data generated by the Phi-TEC II can be used to directly compare the impact of different operating scenarios. From this, the necessary safety controls for the manufacturing plant can be selected. Examples of these are:

- Emergency and evaporation cooling

- Quenching

- Controlled depressurization

- Vent sizing (in accordance with DIERS methodology)

Publications

The following are a list of some technical publications which highlight the use of the equipment.

Thermal hazard assessment using closed-cell adiabatic calorimetry

20-Jul-2023

https://www.sciencedirect.com/science/article/abs/pii/S0950423096000356(Subscription or purchase maybe required for full access)

Reaction hazard and mechanism study of H2O2 oxidation of 2-butanol to methyl ethyl ketone using DSC, Phi-TEC II and GC-MS

Yue Sun, Lei Ni, Maria Papadaki, Zeren Jiao, Wen Zhu, Juncheng Jiang, Chad Mashuga, M. Sam Mannan & Benjamin Wilhite

16-May-2023

https://www.sciencedirect.com/science/article/abs/pii/S0950423020300887(Subscription or purchase maybe required for full access)

The Effects of Acid and Hydrogen Peroxide Stabilizer on the Thermal Hazard of Adipic Acid Green Synthesis

Yinshan Liu, Lei Ni, Hang Yao, Jimi Su & Zhen Cheng

12-Apr-2023

https://www.mdpi.com/2071-1050/15/8/6530(Subscription or purchase maybe required for full access)

Effects of typical additives on the thermal stability of ammonium peroxydisulfate

Mingju Jing, Yingnan Zhang, Jianpeng Wang, Juncheng Jiang Chi-Min Shu and Bin Zhang

06-Jan-2023

https://www.sciencedirect.com/science/article/abs/pii/S0950423023000049(Subscription or purchase maybe required for full access)

Thermal stability evaluation of tert-butyl peroxybenzoate mixed with impurities

Yilin Zhao, Nengcheng Zhou, Min Hua, Xiuxia Guo, Wenxing Zhang, Huichun Jiang, Xuhai Pan & Juncheng Jiang

02-Nov-2022

https://www.tandfonline.com/doi/abs/10.1080/00986445.2022.2126769(Subscription or purchase maybe required for full access)

Effect of reaction type on TMRad, TD24 and other data obtained by adiabatic calorimetry

Xiao-juan Wu, Yi Zhu, Li-ping Chen, Wang-hua Chen & Zi-chao Guo

26-Jun-2021

https://link.springer.com/article/10.1007/s10973-021-10787-2(Subscription or purchase maybe required for full access)

Safety Concerns for MOF Syntheses—Understanding the Behavior of DMF Mixtures at Elevated Temperature and Pressure

Timothy Johnson, Mirza Fejzic, Daren Tee, and Stephen Bennett

10-Mar-2021

https://pubs.acs.org/doi/abs/10.1021/acs.oprd.0c00353(Subscription or purchase maybe required for full access)

Analysis of thermal hazards of tertbutylperoxy2ethylhexyl carbonate by calorimetric technique

Juan Zhou, Chen-Ye Wei, Min Hua, Xu-Hai Pan, Xin-Miao Liang, An-Dong Yu, Cyril G. Suetor & Jun-Cheng Jiang

06-Mar-2021

https://doi.org/10.1007/s10973-021-10619-3(Subscription or purchase maybe required for full access)

Analysis of thermal hazards of tert-butylperoxy-2-ethylhexyl carbonate by calorimetric technique

Juan Zhou Chen-Ye Wei Min Hua, Xu-Hai Pan, Xin-Miao Liang, An-Dong Yu, Cyril G. Suetor and Jun-Cheng Jiang

06-Mar-2021

https://link.springer.com/article/10.1007/s10973-021-10619-3(Subscription or purchase maybe required for full access)

Thermal hazard and reaction mechanism of the preparation of adipic acid through the oxidation with hydrogen peroxide

Wei Jiang, Lei Ni, Juncheng Jiang, Qiang Chen, Zhiquan Chen, Shuliang Ye

02-Oct-2020

https://aiche.onlinelibrary.wiley.com/doi/abs/10.1002/aic.17089(Subscription or purchase maybe required for full access)

Hazard evaluation for chlorination and amination reactions of fluorocytosine production process

Andong Yu, Min Hua, Xuhai Pan, Lei Ni, Xinmiao Liang, Chenye Wei & Juncheng Jiang

01-Oct-2020

https://www.sciencedirect.com/science/article/abs/pii/S095042302030499X(Subscription or purchase maybe required for full access)

Kinetic-parameters-free method of determining autocatalytic decomposition from experimental adiabatic data

Xiao-Qiao Zhao, Hao Wang, Wen-Qian Wu, Jun Zhang, Wang-Hua Chen, Zi-Chao Guo & Li-Ping Chen

01-Oct-2020

https://www.sciencedirect.com/science/article/abs/pii/S0957582020315482(Subscription or purchase maybe required for full access)

Studies on the flame propagation characteristic and thermal hazard of the premixed N2O/fuel mixtures

Yu-yan Li, Rong-pei Jiang, Zhi-peng Li, Sen Xu, Feng Pan & Li-feng Xie

12-Jun-2020

https://www.sciencedirect.com/science/article/pii/S2214914719305537(Subscription or purchase maybe required for full access)

Systematic thermal and flammability hazard analysis of a DMPAT explosion accident in Taiwan

Horng-Jang Liaw & Yuan-Ruei Liou

04-May-2020

https://www.sciencedirect.com/science/article/abs/pii/S0957582020317663(Subscription or purchase maybe required for full access)

Thermal hazard analysis of 1-((cyano-1-methylethyl) azo) formamide and effect of incompatible substances on its thermal decomposition

Andong Yu, Weijun Wang, Min Hua, Xuhai Pan, Xinmiao Liang, Chenye Wei, Chi-Min Shu & Juncheng Jiang

08-Mar-2020

https://www.sciencedirect.com/science/article/abs/pii/S0950423019308046(Subscription or purchase maybe required for full access)

Process hazard evaluation for catalytic oxidation of 2-octanol with hydrogen peroxide using calorimetry techniques

Yue Sun, Lei Ni, Maria Papadaki, Wen Zhu, Juncheng Jiang, Chad Mashuga, Benjamin Wilhite & M. Sam Mannan

15-Dec-2019

https://www.sciencedirect.com/science/article/abs/pii/S1385894719314123(Subscription or purchase maybe required for full access)

The modified Stoessel criticality diagram for process safety assessment

Juncheng Jiang, Wei Jiang, Lei Ni, Wenxing Zhang, Mengya Zou, Saili Shen & Yong Pan

01-Sep-2019

https://www.sciencedirect.com/science/article/abs/pii/S0957582019307918(Subscription or purchase maybe required for full access)

New Thermal Runaway Risk Assessment Methods for Two Step Synthesis Reactions

Juncheng Jiang*, Fusheng Cui, Saili Shen, Xiuxia Guo, Lei Ni & Yong Pan

22-Dec-2018

https://pubs.acs.org/doi/abs/10.1021/acs.oprd.8b00266(Subscription or purchase maybe required for full access)

Process safety evaluation of the synthesis of tert-butyl peracetate

Saili Shen, Juncheng Jiang, Wenxing Zhang, Lei Ni & Chi-Min Shu

15-Mar-2018

https://www.sciencedirect.com/science/article/abs/pii/S0950423017309099(Subscription or purchase maybe required for full access)

Preparation and thermal hazard evaluation of 1,3,3,5-tetra(1H-tetrazol-5-yl)-pentane

Longfei Liu, Lei Ni, Jie Yang, Juncheng Jiang & Gaowen Yang

21-Feb-2018

https://link.springer.com/article/10.1007/s10973-018-7073-6(Subscription or purchase maybe required for full access)

Downloads

The following are a list of available downloads.

High Phi-Factor Test Cell Catalog

Process Safety and Scale Up Specifications