Operating the BioXplorer 100 as a Turbidostat to Maximize High-Density E. coli Cultivation

Need Advice?

Speak with our specialists today to discuss your specific requirements.

Figure 1. H.E.L BioXplorer 100, bench-top parallel 8 bioreactor platform.

Abstract

Precise control of microbial growth is essential in bioprocess development, continuous manufacturing, and microbial physiology studies. Turbidostats, which maintain cultures at a constant cell density by adjusting the inflow of fresh medium in response to real-time turbidity feedback, enable highly stable and reproducible culture conditions.

This application note describes how the BioXplorer 100 (Figure 1) can be operated as a turbidostat using its integrated BioVIS probe (Figure 2) and WinISO software controlled pumping system to maximize high density Escherichia. coli cultivation. A non-linear calibration curve was developed to allow accurate correlation between probe output and cell density at high biomass, where optical scattering effects cause non-linearity.

Once calibrated, the BioXplorer 100 successfully maintained a stable E. coli cell concentration at the defined set point under continuous growth conditions. This supports high-productivity process development, consistent physiological states, and controlled experimental evolution.

Figure 2. BioVIS probe for online monitoring of total cell growth and biomass within a bioreactor

Key Benefits

- Stable high-density operation with automated dilution control

- Consistent cell physiology for long-duration or comparative experiments

- Parallel cultivation capability for screening and optimisation workflows

- No need for external optical monitoring equipment

BioXplorer 100 Operated as a Turbidostat

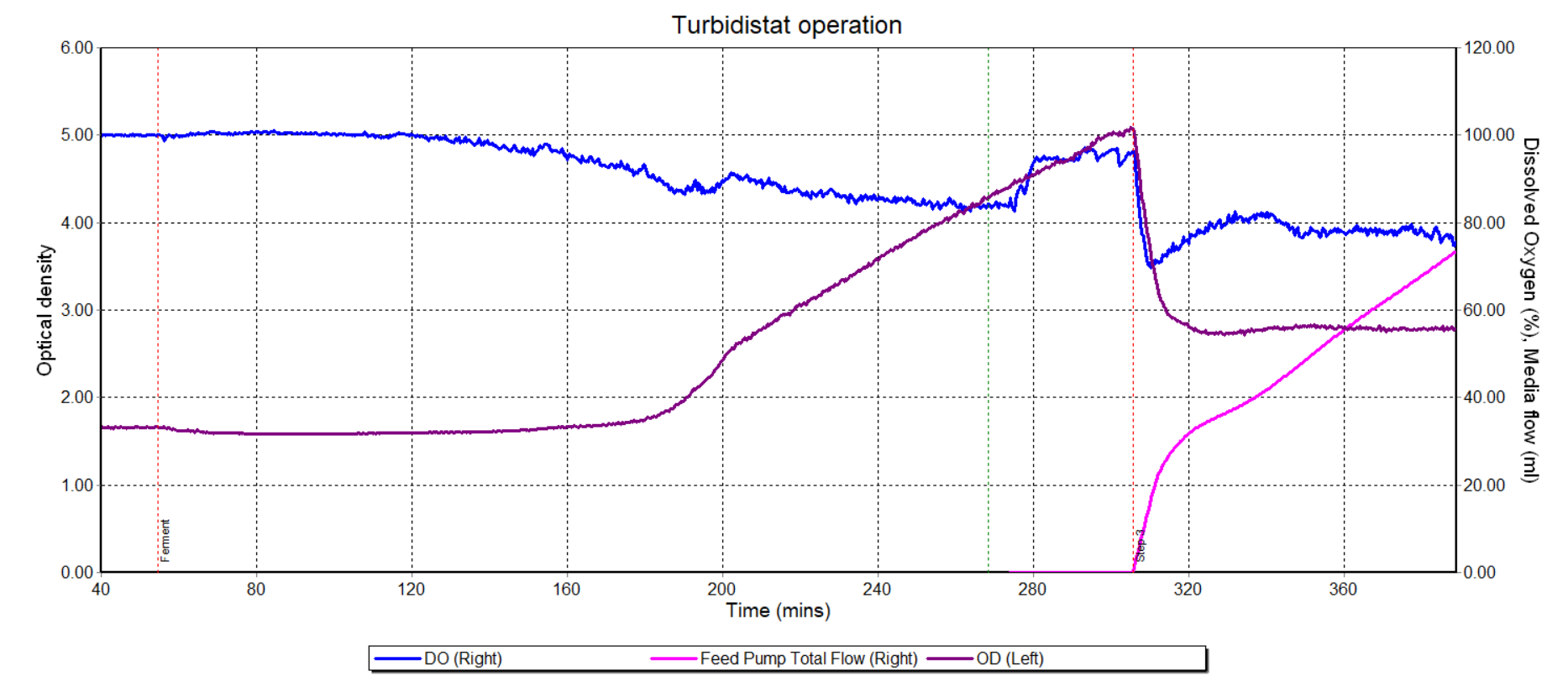

- Initial Growth (~0–155 min): The culture grows from time of inoculation (~55 mins). After a lag phase OD increases and DO decreases as cells consume oxygen.

- Exponential Phase (~155–300 min): The biomass increases rapidly, with continued DO decline reflecting high metabolic activity until 275 mins where DO rises sharply, likely due to media exhaustion.

- Turbidostat Control Activated (~300 min): Upon reaching the OD setpoint, the system automatically starts dilution.

- Feed pump flow increases as fresh medium is added.

- OD stabilises at the defined target.

- Steady-State Metabolic Response: Fresh medium addition dilutes cell concentration to the set-point level, causing DO to rise before returning to a steady level.

Figure 3. Turbidostat control profile of BioXplorer 100

Conclusion

The BioXplorer 100 can be effectively operated as a turbidostat when supported by a non-linear turbidity calibration, delivering stable, controlled high-density cultivation that is reproducible.

By maintaining a stable, high-density E. coli culture under continuous growth conditions, the system enables reproducible steady-state operation with minimal manual intervention.

The combination of real-time biomass monitoring, automated dilution control, and flexible parallel bioreactor configuration makes the BioXplorer 100 well-suited for applications including strain development, process optimisation, adaptive evolution studies, and high-value biomolecule production.

Overall, the BioXplorer 100 provides a reliable and scalable platform for researchers and process developers seeking robust continuous cultivation capabilities.

This performance enables long-duration, reproducible continuous culture, supporting process optimisation, strain development, and high-value biomolecule production with reduced manual intervention and higher experimental confidence.

Want to read more later?

Introduction

Controlling microbial growth in liquid culture is central to biotechnology research and industrial bioprocessing. Traditional batch cultures exhibit dynamic shifts in nutrient availability and metabolic state, making them less suitable when consistency and reproducibility are required.Turbidostats provide continuous cultivation under stable growth conditions, maintaining constant biomass by automatically diluting the culture when turbidity exceeds a defined threshold. This enables:

- Steady-state physiology and metabolism

- Improved reproducibility between experiments

- Long cultivation times without manual intervention

- Increased productivity for biosynthesis and protein expression

- Contributes to microbial physiology and strain development research

The BioXplorer 100 is a parallel, small-scale bioreactor system designed for flexible bioprocess development. Its integrated BioVIS probe provides a continuous, in-situ optical attenuation measurement that can be configured in WinISO to return calibrated OD-equivalent values in real time for automated growth regulation. However, accurate turbidostat operation requires careful calibration between probe signal and optical density (OD600), particularly at high cell densities, where turbidity and OD no longer correlate linearly.

Interested in the BioXplorer 100?

Interested in the BioXplorer 100?

Materials & Methods

Microbial Culture Growth Conditions

- Organism: Escherichia coli

- Culture volume: 50 mL in BioXplorer 100 vessel*

- Temperature: 37 °C

- Agitation: 200 and 400 rpm

- Biomass Set Point: 2.75 g/L

- Control software: WinISO

The BioXplorer 100, equipped with its BioVIS probe, was inoculated with E. coli culture and allowed to grow until reaching the desired biomass setpoint. Once the setpoint was reached, WinISO automatically activated dilution control, adding fresh medium and removing effluent to maintain constant culture volume and biomass.

*50-150 mL culture volume can be used with the Bioxplorer 100 and 120-400 mL culture volume with BioXplorer 400.

The system continuously monitored turbidity and adjusted medium feed in real time, maintaining the target cell density without manual intervention. Surplus culture volume was withdrawn automatically through a dip tube coupled to an independent peristaltic pump for each vessel, controlled and maintained by the WinISO software.

Results & Discussion

Calibration Performance

Dilution, which is routinely performed when preparing offline samples for OD₆₀₀ measurement by UV–Vis spectrophotometry, is not possible when using an in-situ optical probe. Therefore, a non-linear calibration model was required to accurately relate the BioVIS attenuation signal to true cell density at high biomass. This calibration enables the BioVIS signal to be used reliably as the feedback input for continuous culture control.

Non-Linear Calibration of BioVIS Probe

To generate a calibration curve, samples were taken at incremental culture densities and measured offline at OD600 using a spectrophotometer. These OD values were compared to the raw probe signal (transmitted light intensity).

The calibration curve below shows the relationship between the BioVIS probe output and the offline-measured OD₆₀₀ of the E. coli culture. At low cell densities, the absorbance signal and OD₆₀₀ are approximately proportional, meaning the BioVIS output can be interpreted directly when OD₆₀₀ is below ~1.0.

At low OD600, probe response was approximately linear. At higher densities (OD600 at 1.5) increasing light scattering resulted in non-linearity, requiring a non-linear calibration model for accurate biomass interpretation.

As cell density increases, the relationship becomes non-linear. Above ~OD₆₀₀ ≈ 1.5, the BioVIS signal increases more slowly than the true OD₆₀₀. This occurs because dense cultures cause multiple scattering, reducing the fraction of transmitted light detected and breaking the simple proportionality assumed by Beer–Lambert law in dilute solutions.

By applying the non-linear calibration model, the BioXplorer 100 can accurately determine biomass across the full operating range, enabling robust turbidostat control at high cell densities.

Optimise your biomass measurements

Optimise your biomass measurements

Summary

H.E.L’s BioXplorer 100 and BioXplorer 400 parallel bioreactor systems offer valuable turbidostat capability, enabling real time control of culture density for a wide range of media and high-density microbial applications. When combined with the in-situ BioVIS optical attenuation probe and WinISO-controlled automated dilution, these platforms maintain a stable biomass setpoint under continuous cultivation—ideal for long-running, steady-state processes.

The BioXplorer platform as a whole provides consistent cell physiology, reliable long-duration operation, and true parallel cultivation. This makes it exceptionally well-suited for process development, strain optimization, screening studies, and high-value biomolecule production.

Alongside the 100 and 400 systems, the BioXplorer 400P extends the range by offering a robust, scalable option for advanced pressurised bioprocessing applications. Together, the BioXplorer family delivers a comprehensive solution for continuous microbial cultivation with integrated optical monitoring and flexible control strategies.

Explore our BioXplorers

Discover how BioXplorer 100, 400, and 400P systems can enhance control, consistency, and scalability in your microbial processes.

BioXplorer 100 | Bench-Top, Parallel 8 Bioreactor Platform

Bench-top, parallel 8 bioreactor platform, with 50-150ml volume…

BioXplorer 400 | Bench-Top, Parallel 4 Bioreactor Platform

The BioXplorer 400 has 4 reactors with working volumes of up to 400 ml…

Want to move your development forward?

Get in touch with us today to explore solutions tailored to your bioprocessing needs.