Characterization of the maximum heating capabilities of the multi-reactor PolyBLOCK 4

Aliko Chanda, Joseph Willmot

H.E.L Group, 9-10 Capital Business Park, Manor Way, London, WD6 1GW

The maximum heating capabilities of the PolyBLOCK 4 when using a circulator were investigated in this study. The labCONSOL® control software enabled the use of different modes of heating, Heat/Cool Reactor, and Constant reactor. The results show that the PolyBLOCK can achieve a 130 °C temperature difference between the reactor temperature and the circulator temperature. This was achieved for the full temperature range of the PolyBLOCK 4 from sub-ambient conditions to 200 °C. The study also found that the absolute temperature in one reactor has no effect on the performance on the neighboring reactors. A stable ramping rate of 7 °C/min was achieved when heating the reactor contents to 200 °C from 80 °C with a constant circulator temperature of 70 °C.

Table of Contents

Introduction

The PolyBLOCK 4 is a versatile compact parallel reactor block with in-built heating and stirring capabilities. Cooling can be achieved by an external circulator. This piece of equipment is used in chemical synthesis within process development and R&D. The four independently controlled reaction zones are beneficial for Design of Experiment (DoE) studies and are also found in other products such as the BioXplorer and ChemSCAN ranges. Depending on the intended use, the reactor vessel will typically be glass or metal. Glass is often used for general synthesis and laboratory work, while metal – typically stainless-steel (SS316) or Hastelloy (HC276) are used for high-pressure applications. Reactor vessels can range from as low as a 1 mL HPLC vial to 500 mL reactors, with aluminum adaptors available to support the full range of reactor sizes.

This study demonstrates the maximum heating capabilities of the PolyBLOCK 4 by testing different solvents, reactors, and temperature control methods.

Thereby providing a valuable guide to selecting the right combination of these factors when designing an experiment.

Materials and Method

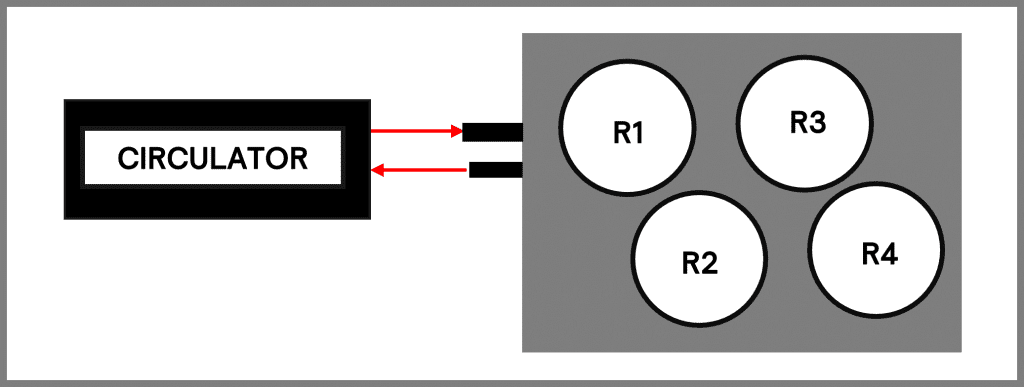

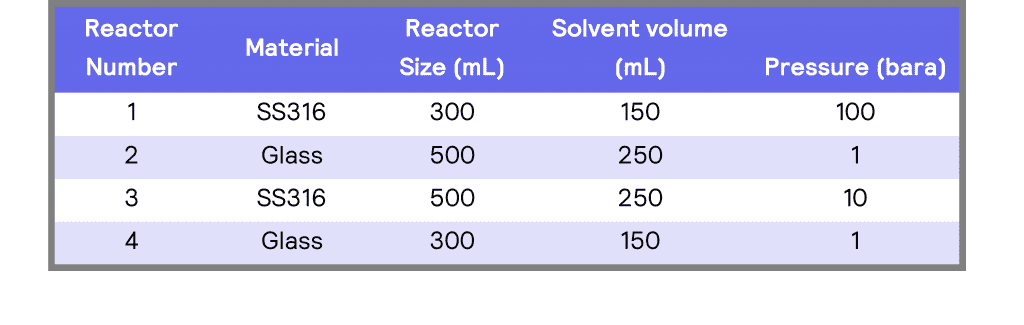

For these characterizations, the PolyBLOCK 4 was used in standard laboratory conditions. Large SS316 and glass reactors were used; the SS316 reactors of 300 mL and 500 mL were placed in positions 1 and 3 (Figure 1). The 500 mL and 300 mL glass reactors were placed in positions 2 and 4 of the reactor (Table 1).

Silicone oil (Huber P20-275-50) was the main solvent used for these tests, due its wide operating range. In all cases, stirring was provided via magnetically coupled agitation provided by the PolyBLOCK in-built magnetic stirrer at 400 rpm. Six-blade PTFE Rushton impellers were used in both the glass and metal reactors. In addition, a Huber Unistat 430 was attached to the PolyBLOCK to provide active cooling. The Unistat 430 is larger than the recommended circulator for a PolyBLOCK. However, it has similar cooling and heating capacities to other smaller models, and thus allows for a performance comparison.

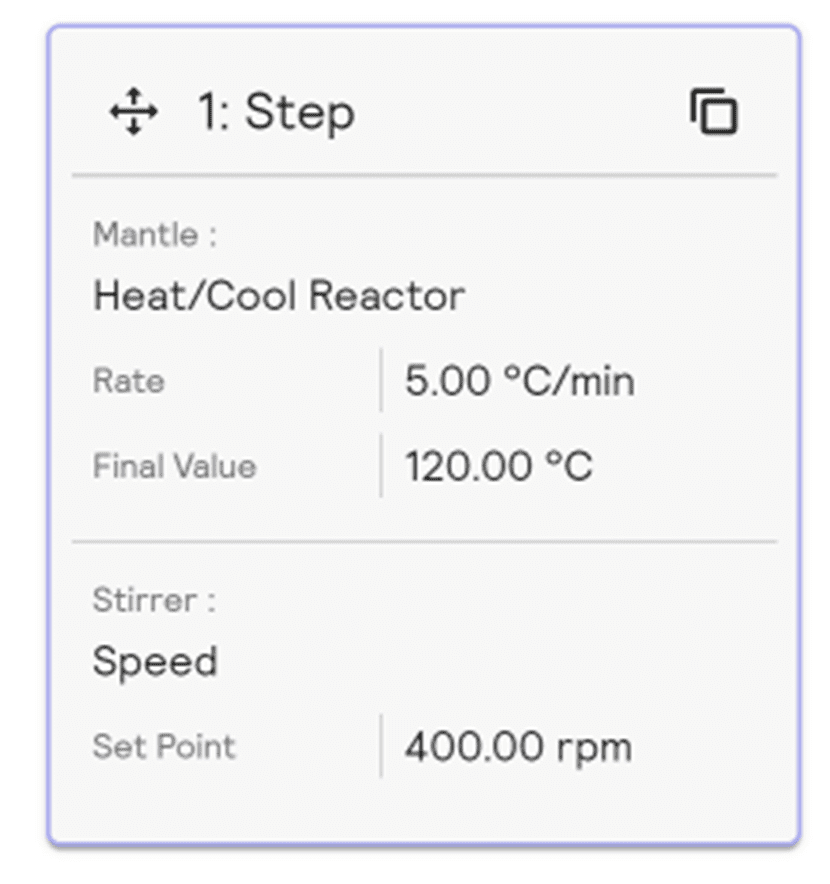

To achieve the maximum operating temperature of a PolyBLOCK, a circulator is not required. The circulator provides active cooling that aids in removing the access heat from a reactor, thus assisting in accurate temperature control. labCONSOL® was used to operate the PolyBLOCK 4, this software can control the reactor in several modes such as Constant Reactor Temperature or Heat/Cool Reactor (ramping reactor temperature). Heat/Cool Reactor changes the reactor temperature at a defined rate -see Figure 2 for example.

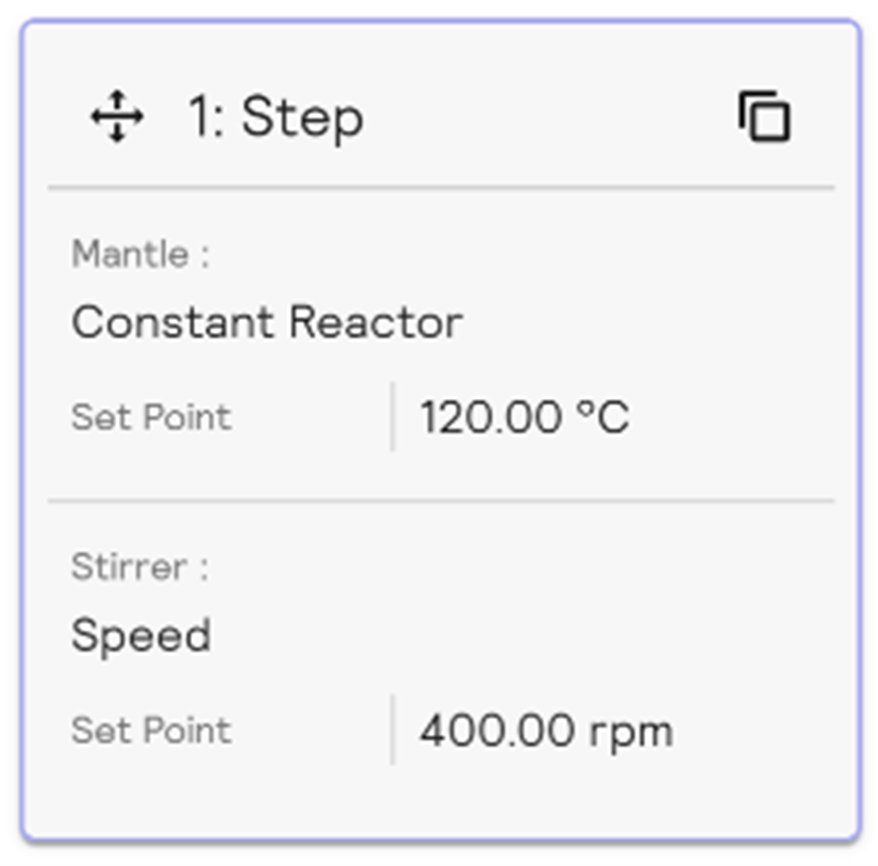

In contrast, Constant Reactor Temperature Control (Figure 3) heats the reactor contents to a specified temperature as quickly as possible. Both heating modes were investigated.

|

|

| Figure 1. Reactor mantle positions within a PolyBLOCK 4 attached to a circulator with oil flow in and out the reactor |

Table 1. Details of the reactors used for heating characterizations, including size material of reactor and solvent volume. |

|

|

| Figure 2. Heat/Cool Reactor step on labCONSOL® heating by 5 °C/min to 120 °C with a stirring speed of 400 rpm. | Figure 3. Step of Constant Reactor on labCONSOL® heating to 120 °C with a stirring speed of 400 rpm. |

Results and Discussion

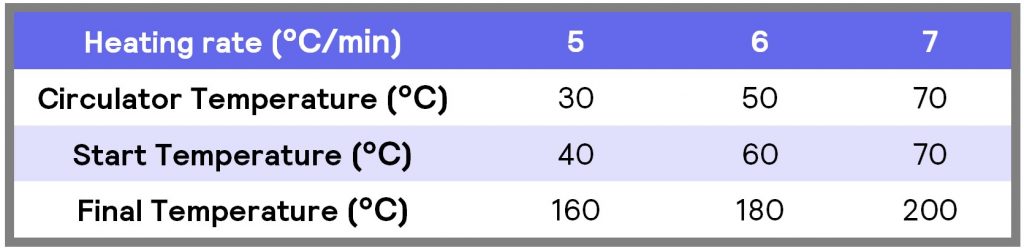

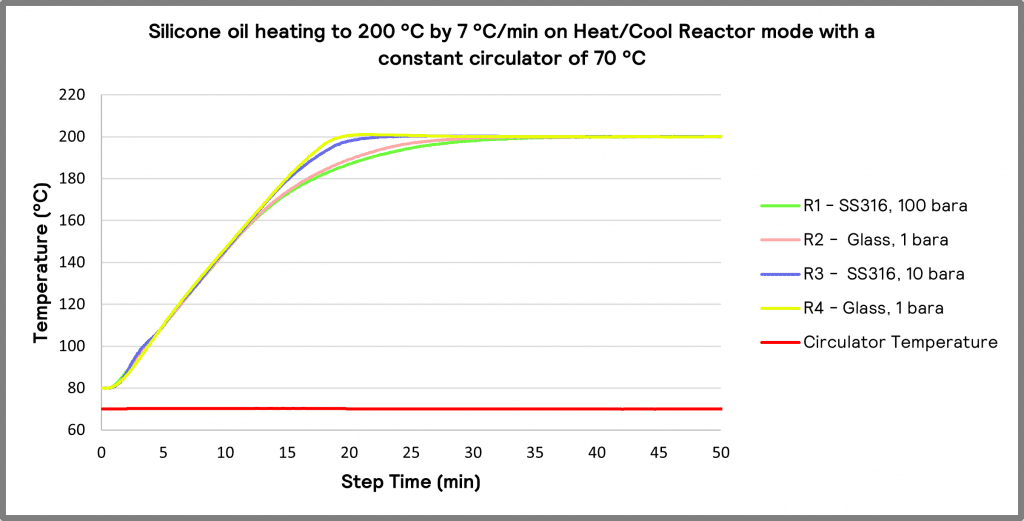

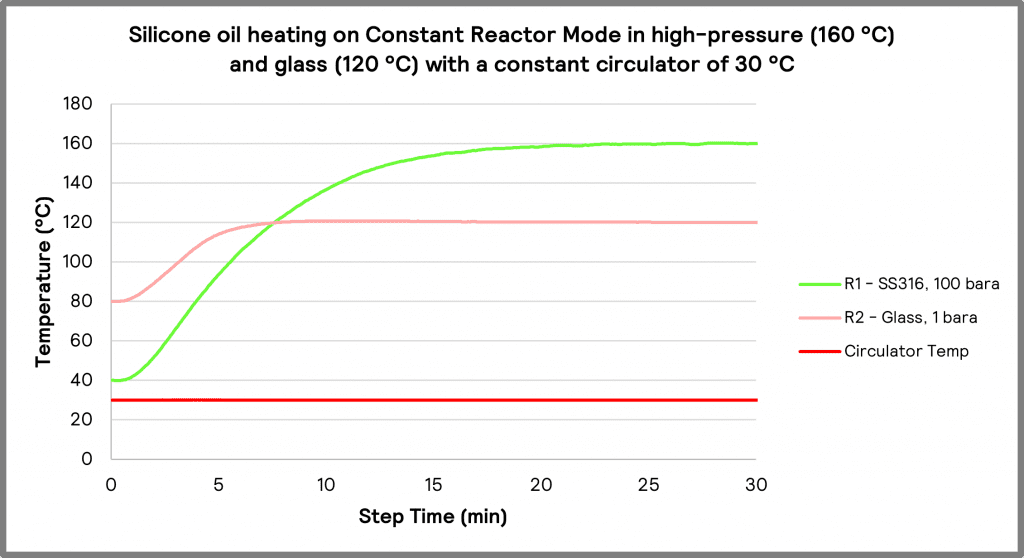

In a previous heating characterization, the PolyBLOCK achieved 7 °C/min when heating to 120 °C/min. These first characterizations evaluated ramping to temperature by 5 °C/min, 6 °C/min and 7 °C/min to 160 °C, 180 °C and 200 °C. The circulator oil temperature was set at 30 °C, 50 °C and 70 °C, respectively (Table 2). This allowed for a maximum temperature difference of 130 °C between the circulator and solvent inside the reactors (Graph 1).

Reactors 1 and 2 took 35 minutes to get to temperature while R3 and R4 only took 25 minutes. No reactor displayed any significant overshoot. The heating profiles between reactors differed from each other between 170 °C and the final setpoint temperature. These results show the impact of factors such as the material of the reactor, and solvent volume that need to be considered for heating applications. Other factors such as stirrer speed and solvent can also affect the results obtained.

|

|

| Table 2. Details of the first characterizations ramping at 5 °C/min, 6 °C/min and 7 °C/min to different setpoint temperatures. | Graph 1. Silicone oil heating to 200 °C by 7 °C/min on Heat/Cool Reactor mode with a constant oil temperature of 70 °C. |

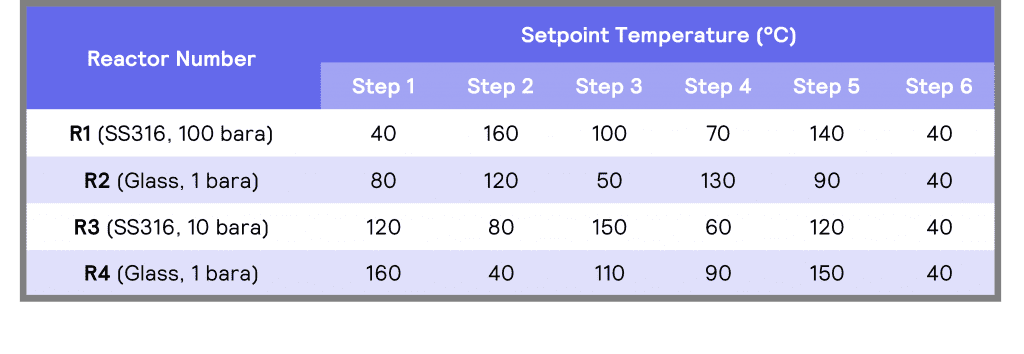

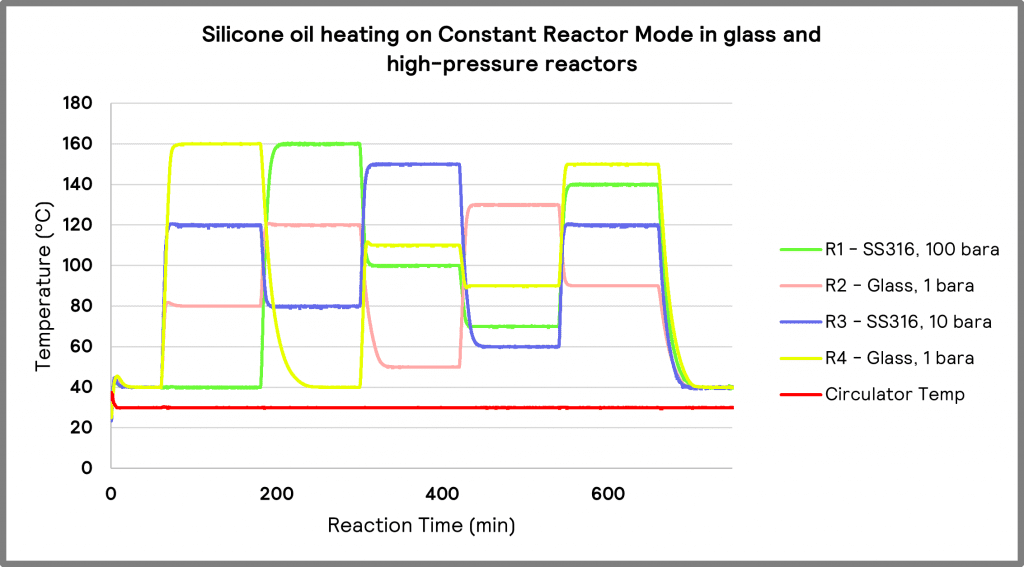

This study also evaluated the impact of simultaneously heating each reactor zone to five different temperature setpoints, ranging from 40 °C to 160 °C (Table 3). During this study, the connected Huber Unistat 430 circulator was set at a constant circulator temperature of 30 °C. These results can be seen in Graph 2, showing that the individual set temperatures of each zone do not have an affect on the neighboring reactors.

In the second step of this test, the results show that shorter temperature changes will occur much faster – as may be anticipated. An example is seen in Graph 3 where heating from 80 °C to 120 °C (pink line) occurred within less than 10 minutes of the step starting. In comparison, the green line shows heating from 40 °C to 160 °C required almost 20 minutes to reach the set temperature. A similar effect is seen when cooling over smaller temperature ranges.

|

|

| Table 3. Details of the reactors heating between 40 °C and 160 °C on Constant Reactor temperature control mode. | Graph 2. Silicone oil heating to different set temperatures on Constant Reactor Mode in glass and high-pressure reactors, with a constant oil temperature of 30 °C using the Huber 430. |

Graph 3. Silicone oil heating on Constant Reactor Mode in high-pressure (160 °C) and glass (120 °C) with a constant oil temperature of 30 °C.

Conclusion

The PolyBLOCK 4 achieved a maximum ramping rate of 7 °C/min (Graph 1) when heating from 80 °C to 200 °C, with a constant circulator temperature of 70 °C. This is an overall temperature difference of 130 °C between the internal temperature of the reactor and the circulator.

Factors such as the material of the reactor or solvent/solvent volume could impact on the rate of heating, meaning the over-all ramping rate for R1 and R2 was 4 °C/min.

Simultaneous, independent heating and cooling of all the reactor zones is possible with the PolyBLOCK 4 (Graph 2). The results show that the different reactor temperatures did not influence the performance of other reactors in the same PolyBLOCK 4. The independent temperatures were not observed to influence the temperature of the circulator.

Acknowledgments

We want to thank the contribution of Dr. Paddy Delaney, for lending us a Huber Unistat 430 for these characterizations and other applications.