Characterization of the maximum heating performance for the multi-reactor PolyBLOCK 8

Aliko Chanda, Joseph Willmot

H.E.L Group, 9-10 Capital Business Park, Manor Way, London, WD6 1GW

In this study, we investigated the maximum temperature heating capacity of the PolyBLOCK 8 when connected to a Silicone oil heating circulator. The results show that the PolyBLOCK 8 can achieve a 90 °C difference between the oil-bath circulator and the internal temperature of both glass and high-pressure (metal) reactor vessels.

Table of Contents

Introduction

The PolyBLOCK 8 is a parallel reactor block with in-built heating, cooling, and stirring capabilities. It can operate as a stand-alone reactor system, and it is also found in many other products such as the ChemSCAN or BioXplorer range. The PolyBLOCK 8 has eight independently controlled reaction zones in a compact footprint. Depending on the intended use, the reactor vessel will typically be glass or metal. Glass is often used for general synthesis and laboratory work, metal – typically SS316 or HC276 – for high-pressure applications.

This study demonstrates the heating capabilities of the PolyBLOCK 8 by testing temperature control methods with various solvents and reactors. Thereby providing a valuable guide to selecting the right combination of these factors when designing an experiment.

Materials and Method

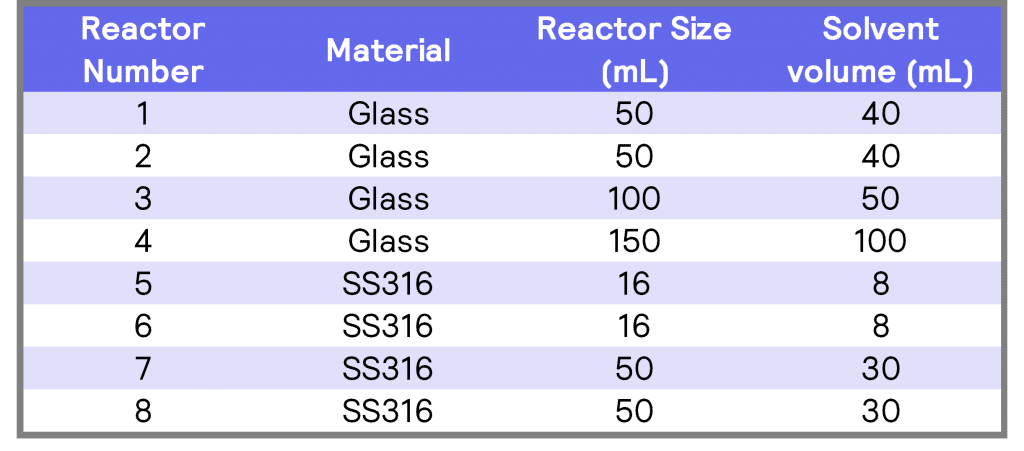

The PolyBLOCK 8 in this study is used in standard laboratory conditions, controlled via labCONSOL® software. In all experiments, glass reactors with PTFE lids of 50 mL, 100 mL, or 150 mL volume were placed in mantles 1 to 4 while positions 5 to 8 had SS316, 200bar rated metal reactors of either 16 mL or 50 mL volume. – Detailed in Table 1.

Table 1. Details of all reactors, including size material of reactor and solvent volume.

Silicone oil (Huber P20-275- 50) was the solvents used for these tests. Six-blade PTFE Rushton impellers were used in the glass reactors, and SS316 anchor impellers were used in the metal reactors. In all cases, stirring was provided via magnetically coupled agitation provided by the PolyBLOCK in-built magnetic stirrer at 400 rpm. In addition, a Huber Unistat 430 was attached to the PolyBLOCK to provide active heating.

Results and Discussion

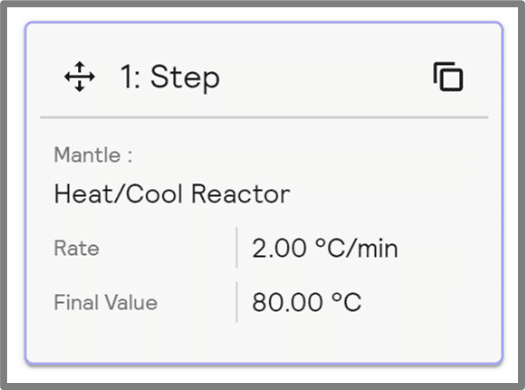

The labCONSOL® software can operate the PolyBLOCK in various modes, such as Heat/Cool Reactor (ramping reactor temperature) or Constant Reactor Temperature.

Heat/Cool Reactor changes the reactor temperature at a defined rate -see figure 1 for example.

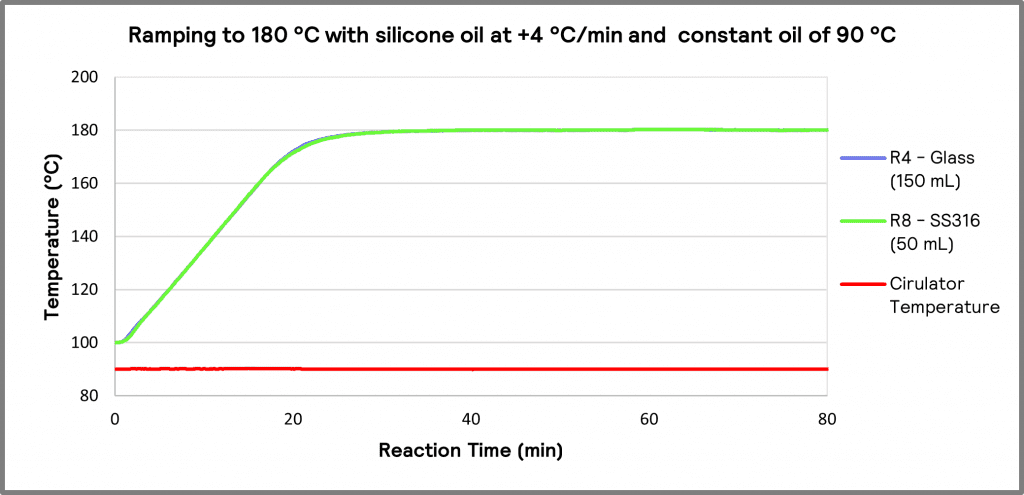

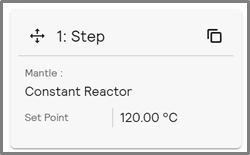

In contrast, Constant Reactor Temperature Control (figure 2) heats the reactor contents to a specified temperature as quickly as possible. Both control modes were investigated.

Silicone oil has a broad liquid phase temperature range, enabling testing across a wide spread of temperature ranges. For simplicity, the results will focus on R4, a 150 mL glass reactor, R5, a 16 mL high-pressure reactor, and R8, a 50 mL high-pressure stainless-steel reactor. These reactors allow for comparison in reactor size, the volume of solvent used, and reactor material.

|

|

| Figure 1. Heat/Cool Reactor plan heating by 2 °C/min to 80 °C | Figure 2. Step of Constant Reactor heating to 120 °C |

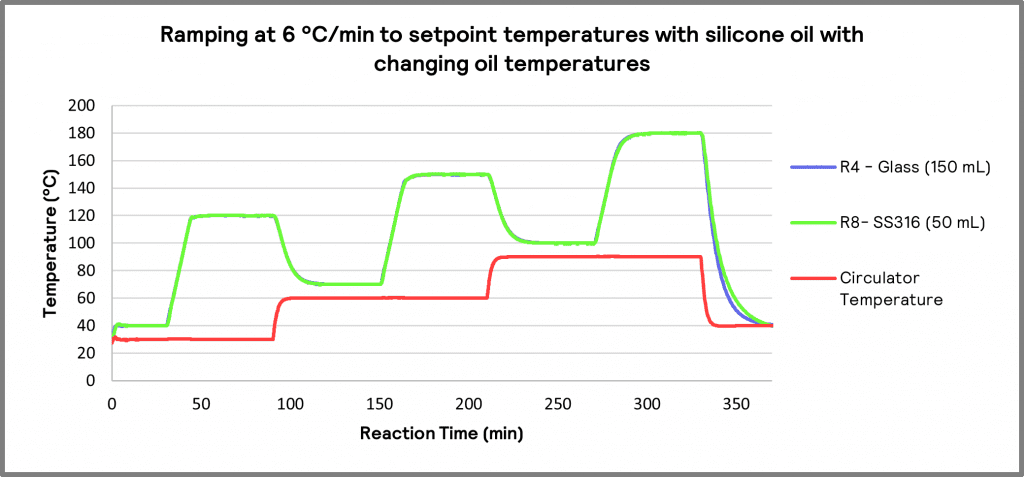

All reactors utilized plans consisting of these steps:

- Heating from 40 °C to 120 °C with a circulator temperature of 30 °C

- Set circulator temperature to 60 °C and reactor temperature to 70 °C

- Heating from 70 °C to 150 °C with an oil temperature of 60 °C

- Set circulator temperature to 90 °C and reactor temperature to 100 °C

- Heating from 100 °C to 180 °C with an oil temperature of 90 °C

- Cool to ambient

When testing larger temperature differences, ramping the reactor temperature to each setpoint at +6 °C/min takes an average of 30 minutes for the reactor temperature (graph 1) to stabilize at the setpoint. This data demonstrates a maximum heating capability of +90 °C between the circulator temperature and the absolute reactor temperature on a PolyBLOCK 8 in both glass and high-pressure reactors.

The PolyBLOCK 8 can heat each reactor to a different temperature, starting at +10 °C above the circulator temperature, with a maximum temperature of +90 °C above the circulator temperature.

Therefore, an overall 80 °C range of reactor temperatures is possible on a PolyBLOCK 8.

Graph 1. Reactors 4 and 8 heating at 6 °C/min to setpoint temperatures with changing circulator temperatures.

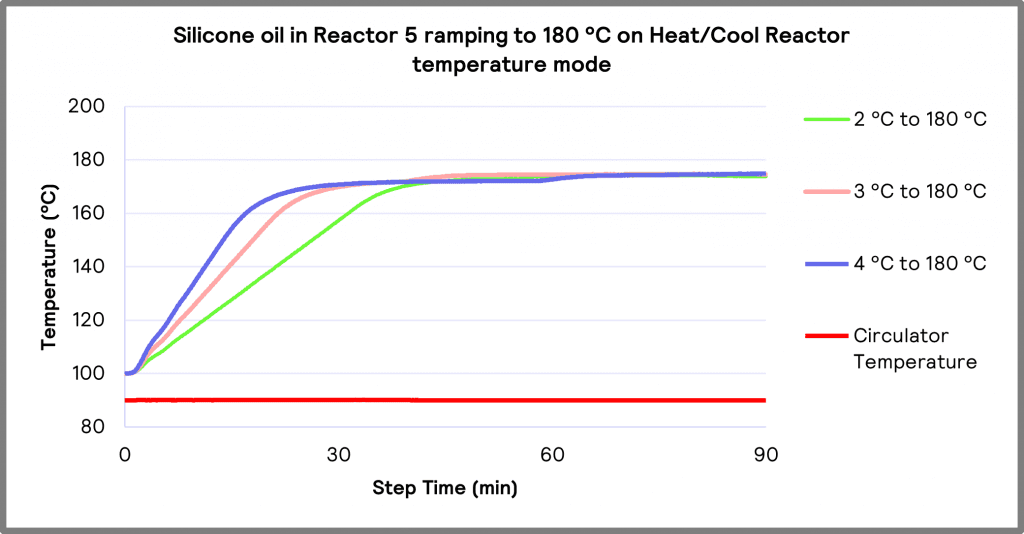

In Reactor 5, a 16 mL stainless-steel reactor, only 8 mL of Silicone oil was used. Graph 2 shows the oil being heated at different ramping rates.

These results are slightly different in comparison to those seen for the two larger reactors in graph 1. Due to its smaller size and smaller solvent volume, R5 could only achieve an 80 °C difference between the oil jacket and the absolute reactor temperature. In turn, this enables an overall 70 °C temperature range difference between different reactors – assuming all reactors were 16ml SS316 containing small solvent volumes. This data is beneficial for ChemSCAN users, as the system typically utilizes 16ml high-pressure reactors and will aid experimental design.

When ramping at a slightly lower rate, there is better stability at +4 °C/min or lower (graph 3). Ramping at lower rates gave greater stability and consistency of temperature control in all reactors, with data showing no significant overshoot.

Conclusion

The PolyBLOCK 8 has shown excellent temperature control when combined with an oil-bath circulator for high-temperature applications. It has been demonstrated that heating at ±6 °C/min is possible in Heat/Cool Reactor (ramping) temperature control mode across the PolyBLOCK’s full temperature range.

When using 50 mL to 150 mL glass and high-pressure reactors, a 90 °C difference can be achieved between the reactor temperature and the circulator temperature. In reactors such as R5, a difference of 80 °C can be achieved.

For D.O.E studies that require rapid temperature increases, it is anticipated that Constant Temperature control mode will help facilitate this.

One other critical takeaway from this characterization study is that your solvent volume and the reactor’s material are important considerations in experimental design.