Chemical Hazard Screening – “Less Is More?”

Need Advice?

Speak with our specialists today to discuss your specific requirements.

Phi-TEC II and TSu

Introduction

A range of instruments are used to predict the potential fire and explosion hazard of chemical reactions. The focus is often on sophisticated devices operated by highly skilled scientists with a view to accurate prediction of the risk, taking weeks and possibly months to reach a conclusion. However, taking a wider view of available tools, specifically simpler screening devices, may reveal an important complementary role with many advantages.

Key Benefits

- Rapid identification of exothermic and runaway reaction hazards

- Cost-effective early-stage chemical hazard screening

- Clear screening decisions with minimal analysis

- Smarter use of detailed hazard testing resources

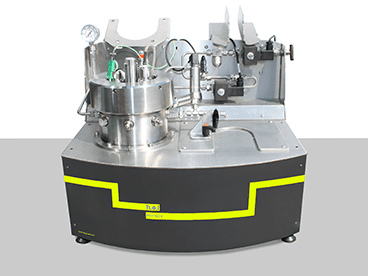

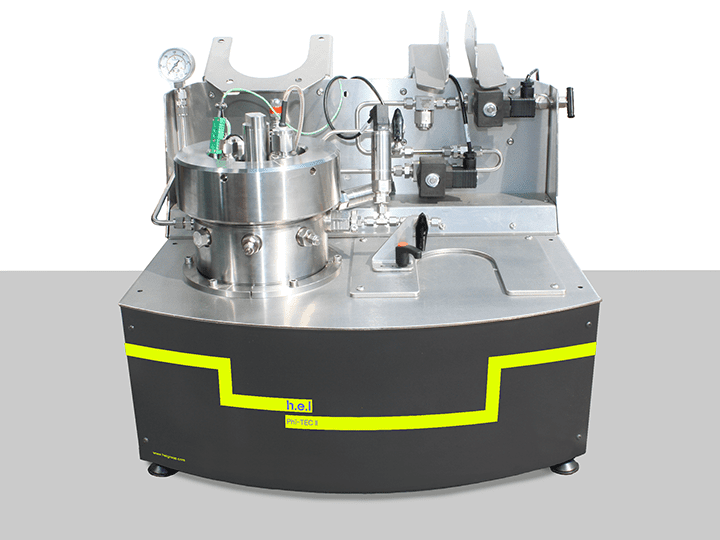

Detailed Study of Runaway Reaction (Phi-TEC II)

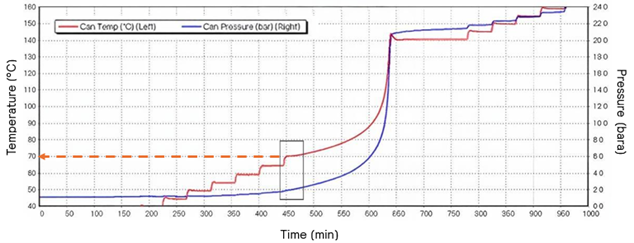

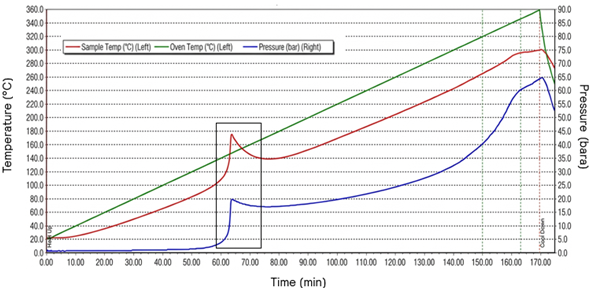

- Consider investigation of the hazard associated with 20% N-Methyl-N-nitroso-p-toluenesulfonamide (NMTS) in Dioxane, the reaction to be conducted in a reactor at 60 oC. The data in Figure 1 show the results of a study from room temperature to 160 °C in an adiabatic calorimeter (Phi-TEC II) that uses special low phi-factor test cells. In this test, the sample is heated in 5 oC steps, each step followed by a “search” period to confirm evidence of an exotherm, at that point switching until a runaway reaction is detected.

Figure 3. Turbidostat control profile of BioXplorer 100

An exotherm is detected near the intended reaction temperature (indicated by the rectangle) and would need serious consideration. The reaction runs away to a pressure of around 20 bar, which could violently rupture the reactor full of toxic chemicals.

This is an example of a test performed to identify in detail the “onset” temperature of the runaway. As each incremental temperature step can take over 30 minutes to complete, the experiment will inevitably take a long time and produce a large amount of data. Figure 2a and Figure 2b show the Phi-TEC II instrument and a corresponding test cell, respectively. Their specialized design allows the collected data to closely replicate the behavior of large‑scale equipment under adiabatic conditions.

The time, effort and cost involved with this approach may not always be required, depending on the specific process.

Figure 2a: A Phi-TEC II

Figure 2b: A Phi-TEC II test cell

Need definitive data on runaway risk?

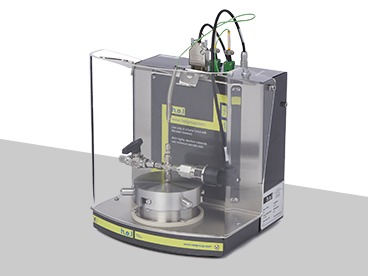

Rapid Reaction Screening (TSu)

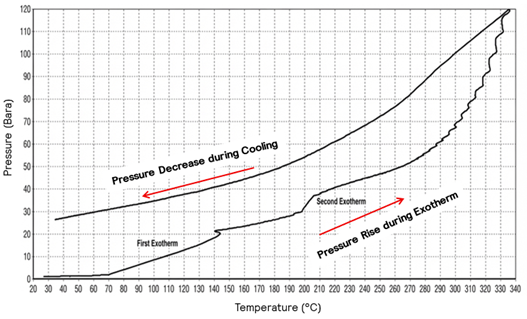

Test data from the same chemical sample, in a TSu (Thermal Screening Unit) device, is shown in figure 3, which took under 3 hours to complete (compared to the previous test that took around 17 hours).

The onset of the exotherm (indicated by rectangle) is clear and starts near the intended operating temperature and reaches a pressure of around 20 bar, similar to the data from the Phi-TEC II.

Figure 3: Pressure and Temperature of NMTS from the TSu test

Although the detection of the exotherm from the two instruments are in agreement, it is important to note that the rate data from the TSu test cells suppress the rate of pressure and temperature rise and so the results do not mimic larger scale vessels. In many cases the detection of the exotherm alone eliminates the requirement for more detailed testing in an adiabatic calorimeter (Phi-TEC II).

Figure 4a and Figure 4b show the TSu instrument and a corresponding test cell, respectively.

Figure 4a: A TSu Screening Device

Figure 4a: 10 mL test cells

Deeper analysis of the TSu data can reveal other useful information. For example, see the plot of pressure as a function of temperature in figure 5, showing the pressure rise during the exotherm and then fall as the sample was allowed to cool. At the end of the experiment, close to room temperature, the pressure is ~ 20 bar higher than the beginning of the experiment. This indicates that the reaction products at the elevated temperature decomposed to non-condensable gases (such as N2), an observation that is only possible if the test cell used in the experiment survives the maximum pressure reached.

Figure 5: Pressure and Temperature of NMTS from the TSu test

Want faster answers on reaction safety?

Conclusions

The Phi-TEC II and TSu are not competing instruments, but rather complementary devices and best considered as part of the overall hazard assessment strategy.. The TSu can play an important role in the overall objectives of hazard assessment as it provides critical data in a rapid and cost-effective way.

Here are some key points about TSu:

- Small footprint, simple to operate by general laboratory staff.

- Very low operating cost and initial investment

- Capable of testing pure samples or mixtures

- Easy to draw basic conclusions without any calculations.

- Quickly identifies relatively safe reactions which need no further tests

- Temperature and pressure data provides quantitative hazard insight.

Thus, many samples can be screened with the TSu, avoiding the need to guess which ones should be subjected to the longer more elaborate tests. As a result, all samples that require detailed analysis receive it, without wasting resources on those that don’t.

Interested in the BioXplorer 100?

Optimise your biomass measurements

Explore our Systems

Discover how Phi-TEC II and TSu work together to deliver fast chemical hazard screening and in-depth runaway reaction analysis.

Ready to take the guesswork out of reaction safety?

Get in touch with us to explore screening and calorimetry solutions tailored to your process safety needs.