Accelerate your bioprocess

development journey

development journey

Optimize your biological processes and screening with award-winning, highly flexible, parallel systems.

Contact us today to find the perfect system for your pressure, volume, and agitation needs.

The BioXplorer range enables you to accelerate your bioprocess development, whilst keeping costs low. Our parallel bioreactor systems enable you to make decisions faster using more reliable, scientifically robust data.

Advantages of a BioXplorer system

- Accelerate screening and optimization by running up to 8 bioprocesses in parallel.

- Drive accurate decision making with comprehensive, scalable, real-time process data.

- Match the needs of any bioprocess with the fully configurable and customizable BioXplorer.

- Control your process with flexible easy-to-use software.

- Future proof.

- Save space and money by working at low volume and at bench scale.

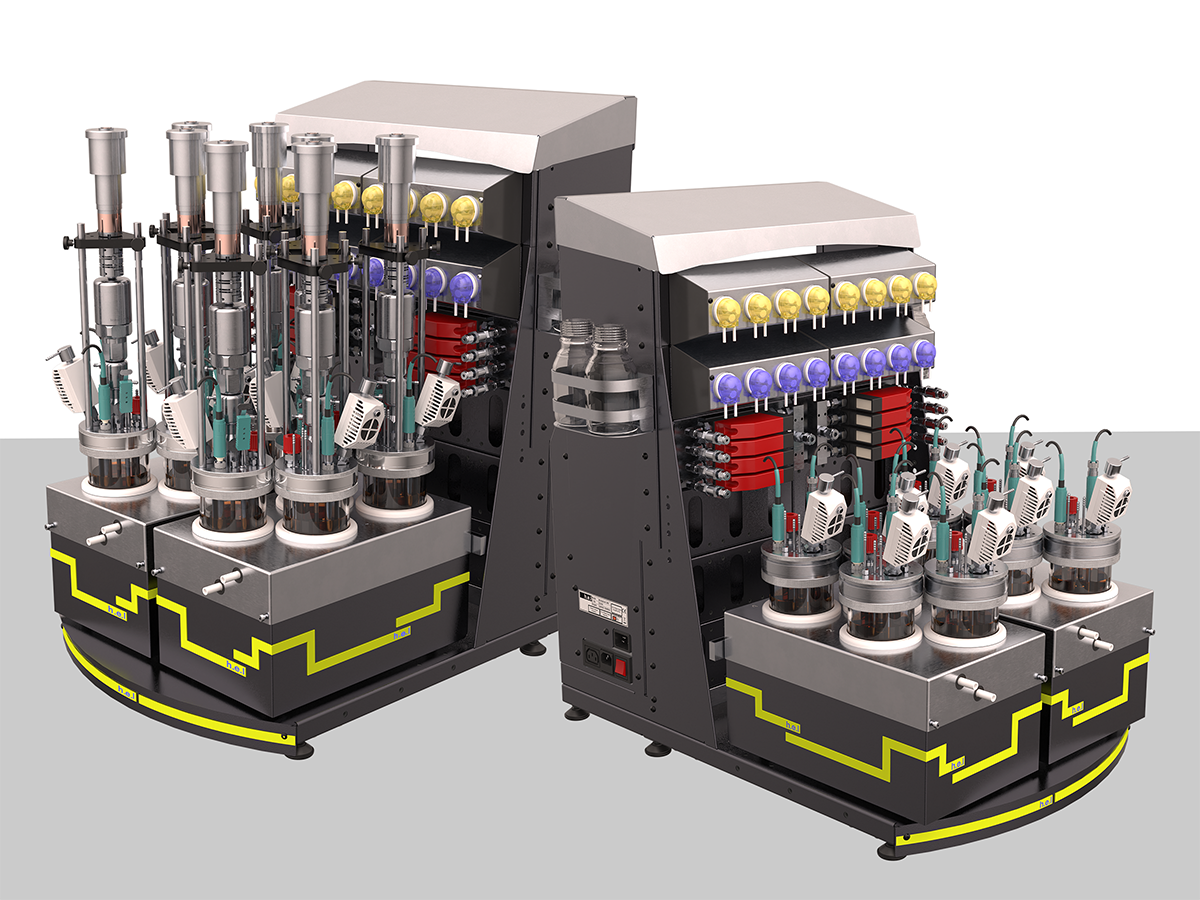

The BioXplorer 100 features 8 sensor-loaded bioreactors, which can be controlled independently or in parallel. Bioreactors have been designed for ease of use with low working volumes and to use magnetic agitation. The system’s modular design allows accurate and precise additions of liquids and gases, controlled by up to 4 sets of peristaltic pumps and up to 2 sets of mass flow controllers, respectively. Versatile, easy-to-use software is combined with modular hardware to give complete control of 8 bioprocesses at one time.

Benefits

- Optimized for aerobic fermentation

- 8 parallel reactors for faster screening

- Maximize information, minimize costs

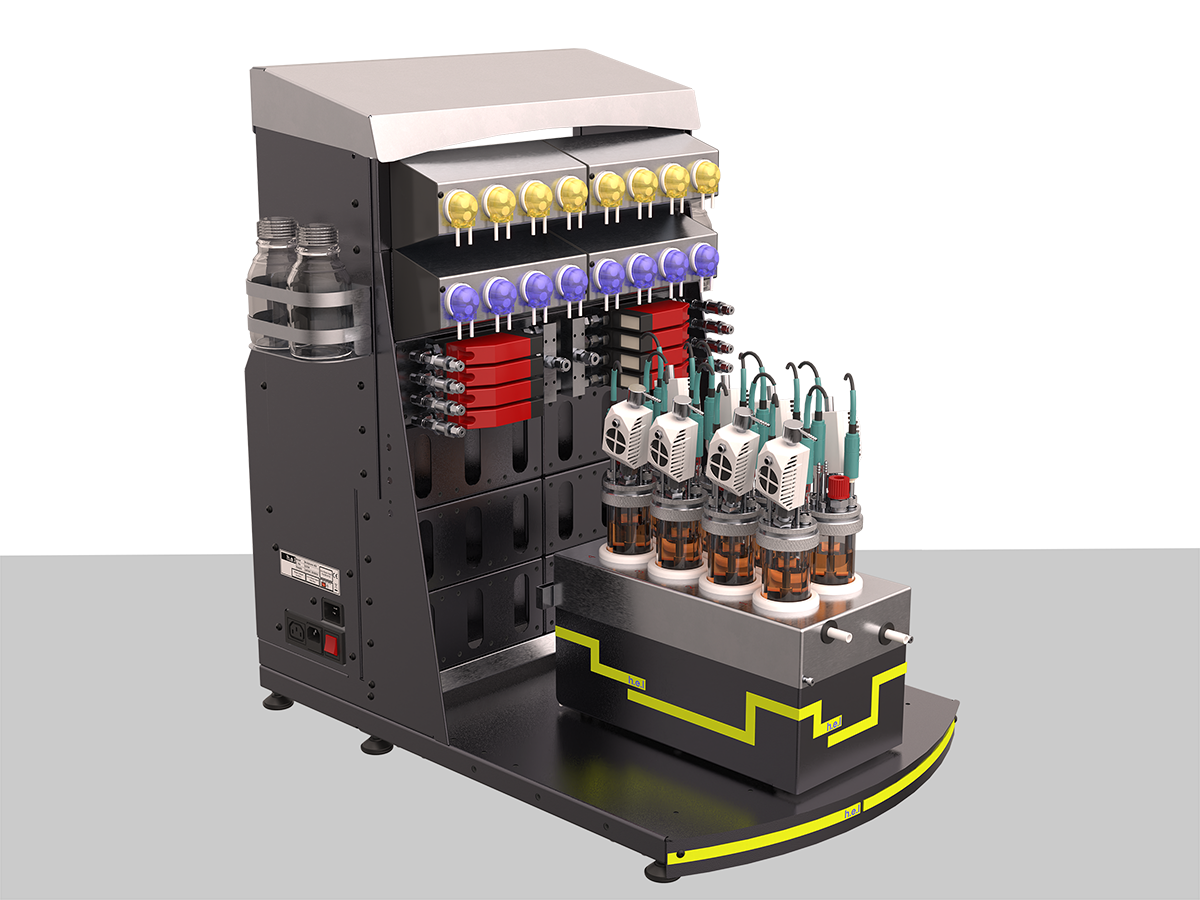

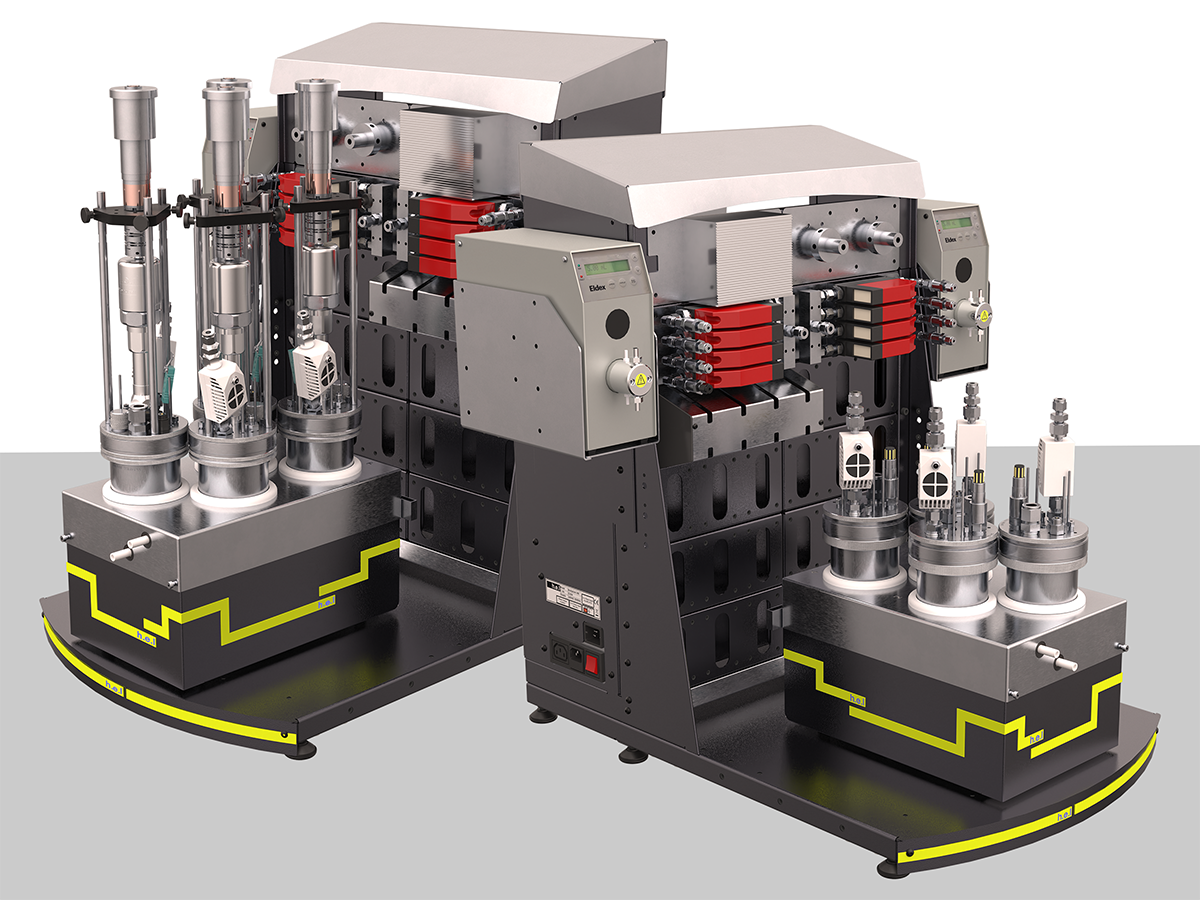

The BioXplorer 400 features 4 sensor-loaded bioreactors which can be controlled independently or in parallel. The system’s modular design allows accurate and precise additions of liquids and gases, controlled by up to 4 sets of peristaltic pumps and up to 2 sets of mass flow controllers. Versatile, easy-to-use software is combined with modular hardware to give complete control of 4 bioprocesses at one time.

Benefits

- Highly configurable

- Easy set-up

- High flexibility

- Enhanced agitation available for challenging bioprocesses

- Higher gas transfer rates deliver more oxygen

- Overcome viscosity

- Cultivate shear-sensitive cells

The BioXplorer 400P is a unique bioreactor system designed for use at pressures up to 10 bar. Working at pressure increases dissolved gas concentrations allowing higher cell density and product yields. The ability to run 4 sensor-loaded bioreactors in parallel at elevated pressure enables syngas process development to move at a pace that would otherwise be impossible. Gas addition rates for up to 4 gases are precisely controlled using mass flow controllers. Upto 3 liquid feeds via peristaltic pumps are also available. Versatile, easy-to-use software is combined with modular hardware to give complete control of 4 high-pressure bioprocesses at one time.

Benefits

- Optimized for syngas fermentation

- Unique parallel, pressure bioreactor system

- Balances cost, ease of use, and performance

- Maximize gas transfer rates of up to 4 gases

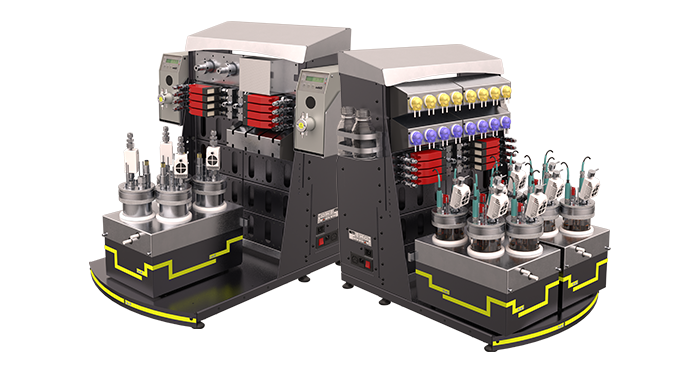

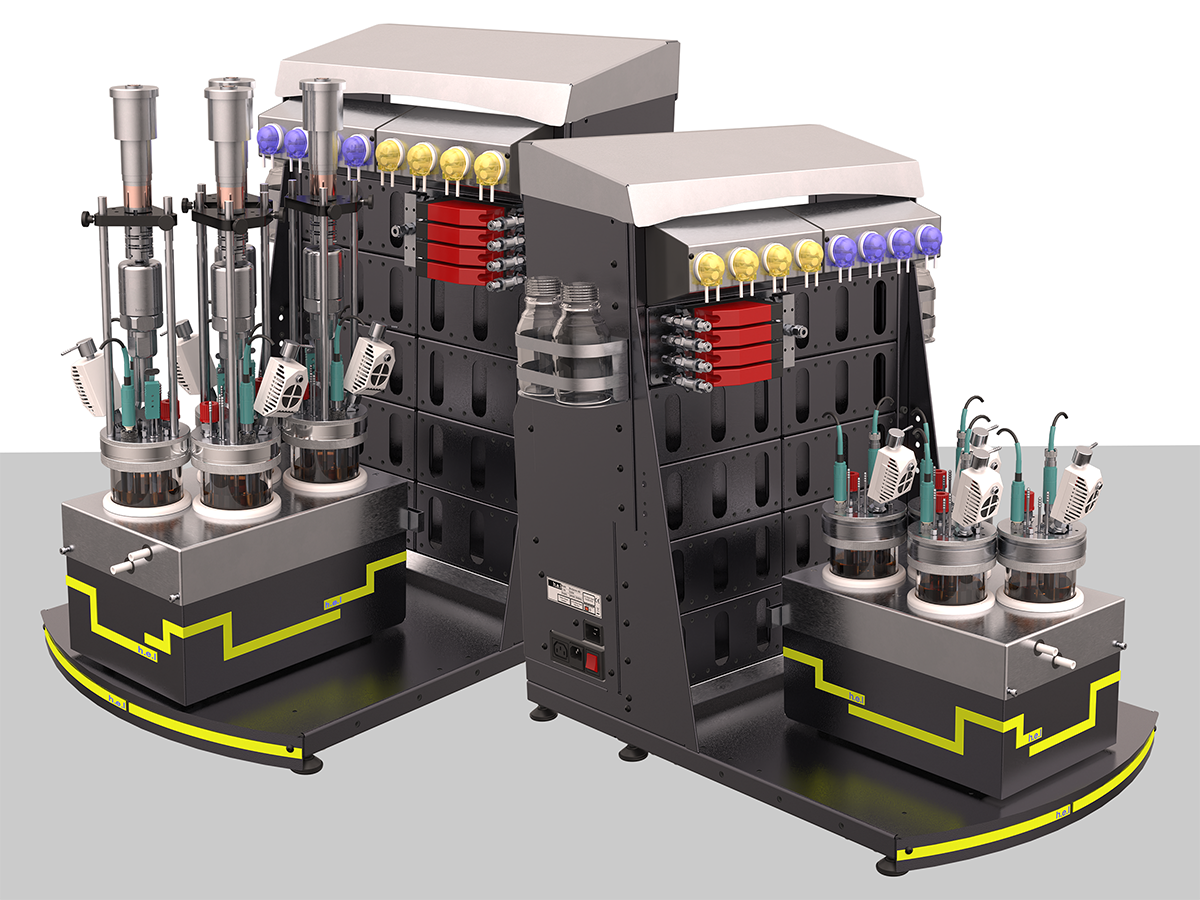

The BioXplorer 400XL features 8 sensor-loaded bioreactors, which can be controlled independently or in parallel. The system’s modular design allows accurate and precise additions of liquids and gases, controlled by up to 4 sets of peristaltic pumps and up to 2 sets of mass flow controllers. Versatile, easy-to-use software is combined with modular hardware to give complete control of 8 bioprocesses at one time.

Benefits

- Easy set-up

- 8 parallel reactors for faster screening

- Maximize information and flexibility

- Enhanced agitation for challenging bioprocesses

- More scalable data