In our second part on battery testing (2019/2020), we highlight the unique applications that our customers use on our equipment. It’s always great to see this work get the recognition it deserves from its peers.

Part 1 of our blog can be found here.

We have prepared a short summary of each publication, listed below.

Contents

1. Revealing the multilevel thermal safety of lithium batteries

1. G. Xu, L. Huang, C. Lu, X. Zhou and G. Cui, Energy Stor. Mater., 2020, 31, 72-86.

Revealing the multilevel thermal safety of lithium batteries

(Subscription or purchase required for full access)

This review discusses the safety of Li-ion batteries (LIBs), which, when operated under abusive conditions, could lead to a thermal runaway – with thermal safety assessments lagging behind energy density improvements. Adiabatic reaction calorimetry (ARC) is used to study “worst case” scenarios in thermal safety, ranging from battery material selection, to single cells, to the testing of complete battery packs.

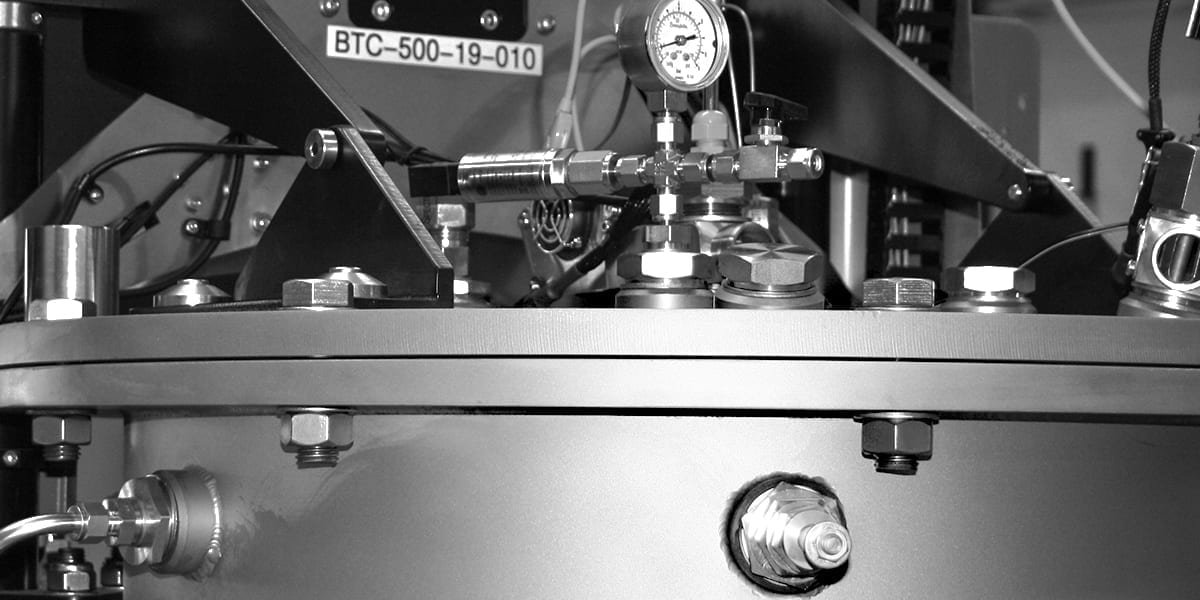

The BTC-130 and BTC-500 are adiabatic reaction calorimeters. Their functions include measuring thermal stability of electrodes, electrolytes and electrode/electrolyte interaction, electrolyte formation, thermal runaway features under any state of charge (SOC) and any state of health (SOH) under abuse conditions. The data obtained includes onset temperature of self-heating, onset temperature of thermal runaways , indications of maximum temperature, self-heating rate (SHR), temperature distribution, pressure, pressure growth rate (PGR), online visual viewing etc. The review summarises by stressing that highly integrated ARC technology in safety testing plays a crucial role in evaluating the safety of LIBs and varied energy storage devices, allowing for a comprehensive understanding of complex battery safety issues and thus leading to safe use and risk management.

2. H. Zappen, G. Fuchs, A. Gitis and D. Sauer, Batteries, 2020, 6, 25.

In-Operando Impedance Spectroscopy and Ultrasonic Measurements during High-Temperature Abuse Experiments on Lithium-Ion Batteries

(Open access article)

This article presents a series of high-temperature abuse experiments on a nickel-manganese-cobalt oxide (NMC)/graphite lithium-ion battery cell, using advanced in-operando measurement techniques. The BTC-500 adiabatic calorimeter was used in 3 high-temperature abuse experiments to detect for any safety critical degradation processes occurring at high temperatures. For the first two experiments, the amplitude of the cells were varied, and in the third, the state of charge (SOC) was increased from 50% to 100%. Electrochemical Impendence Spectroscopy (EIS) data was used to measure the impendence of the battery over various frequency ranges. Using these methods, degradation effects at elevated temperature were observed in real time. The publication concludes that these methods are highly useful during battery cell development, validation, characterization, and as online diagnostics in a battery management system in safety-critical applications.

3. H. Popp, N. Zhang, M. Jahn, M. Arrinda, S. Ritz, M. Faber, D. Sauer, P. Azais and I. Cendoya, Elektrotech.Inftech., 2020, 137, 169-176.

Ante-mortem analysis, electrical, thermal, and aging testing of state-of-the-art cylindrical lithium-ion cells

(Open access article)

This study benchmarks eight different high-energy cylindrical cells concerning their suitability for automotive applications, giving a holistic overview and comparison between them.

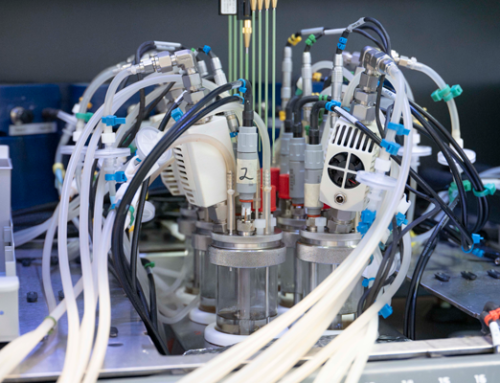

The iso-BTC was used to carry out thermal duty measurements on the batteries under isothermal conditions. Using the power compensation principle, cell surface temperature is actively controlled to a precise temperature setpoint, utilizing the closed-loop control system of the iso-BTC.

The results showed that heat generation rate (HGR) measured at lower temperatures, and higher current rates showed variance of 0.9 W. The study concludes that even when applying similar concepts like Nickel-rich cathodes with graphite-based anodes, the cells show wide variations in their performance under the same test conditions, which could lead to improved vendor selection.

4. Y. Wang, Z. Zhang, L. Dong and Y. Jin, J. Membr. Sci., 2020, 595, 117581.

Reduced shuttle effect by dual synergism of lithium–sulfur batteries with polydopamine-modified polyimide separators

(Subscription or purchase required for full access)

This publication investigates polydopamine (PD) for polyimide (PI) separator coated-modification in lithium-sulfur (Li-S) batteries. Using the BTC-130, the thermal runaway of cells with either PP or PI-PD separators were measured adiabatically.

Thermal runaway using the commercial PP separator was observed at 190 °C, whereas using the PI-PD this occurred at 300 °C. The article concludes the PI-PD separator improves the safety of the battery as the thermal runaway temperature of battery with PI-PD is significantly higher than those found commercially. Li–S batteries with PD as a separator coating also show excellent electrochemical performance and increased security. Therefore, the introduction of PD as material for a coated separator is a promising method for use in Li–S batteries.

And finally, I’d also mention our own recent webinar on applications of isothermal calorimetry battery testing, which is accessible here.

Let us know in the comments below if there are any other publications you fell we should include on the list. We’d also love to talk to you about any future work that you are planning to publish, or would like some help with.