The industry has faced a multitude of challenges historically: reducing production prices, shortening production time, increasing yields… Recently, the focus has expanded to include environmental sustainability, necessitating greener industrial processes through alternative reagents and reactions.

Pressure has positioned itself as a powerful tool for achieving these goals in various industries, including pharmaceuticals, chemical synthesis, and bioprocesses.

In this blog post, we explore the underlying mechanisms by which high-pressure conditions can benefit industrial processes, both from a yield and sustainability perspective, while also offering insights into challenges associated with it.

Effects of High Pressure on Chemical Reactions

Pressure is the force exerted on a substance. It heavily impacts chemical reactions, especially those involving gases. Elevating total pressure increases molecular density, leading to a higher frequency of collisions and potentially accelerated reaction rates.

In homogeneous conditions, increased pressure drives the equilibrium toward the side with fewer molecules. In heterogeneous reactions, gases are notoriously hard to dissolve in liquids. However, increased pressure enhances their solubility, making them more available for chemical reactions.

This behavior is particularly important in processes such as organic synthesis and gas-phase reactions, where efficient gas-liquid interactions are fundamental. For example, hydrogenation reactions benefit greatly from high-pressure conditions within a pressure reactor, as it increases the solubility of hydrogen gas in the liquid phase, accelerating reaction rates and improving yields. Similarly, pressure can be strategically used to optimize downstream processes, reducing energy consumption and waste.

High Pressure in Bioprocess Engineering

Bioprocesses, involving cells or cellular components, typically occur in liquid phases. Gas bioavailability often limits processes requiring gases such as CO₂ fixation in autotrophic pathways or hydrogen oxidation. This limitation is even more critical when utilizing aerobic organisms requiring oxygen. High microbial activity rapidly depletes oxygen, reducing activity and leading to cell death. Implementing high pressure can increase oxygen transfer, helping to mitigate this limitation. This leads to enhanced growth, increased productivity, and more efficient downstream processes.

Certain organisms, such as piezophiles, thrive under high-pressure conditions, offering unique opportunities in bioprocess engineering. High-pressure systems ensure that essential gases like oxygen or carbon dioxide are readily available for microbial or enzymatic processes, supporting efficient cellular metabolism and productivity.

High pressure and Sustainability

Industries face an ever-growing pressure to deliver more efficient and productive processes. However, legislation has been put in place around the globe to reduce emissions and protect the environment, which puts extra strain on industrial processes and bioprocesses.

However, pressure can be a fundamental lifeline for achieving both goals, increasing productivity and making processes greener. Increasing pressure can be seen as an extra expense. Nevertheless, this can result in faster processes, generating high-value products in a shorter time. When polluting gases such as CO2 are a by-product of the process, high pressure can help to reduce its production, pushing the equilibrium away from the gaseous products.

Decarbonization strategies, such as CO₂ fixation, benefit from high-pressure conditions. Whether through chemical reactions or bioprocesses, increased pressure can enhance carbon input and process productivity. This approach enables the production of biofuels or pharmaceuticals from inexpensive carbon sources, creating environmentally friendly and economically viable processes.

Moreover, pressure can reduce the environmental impact of industrial processes by minimizing waste and optimizing resource utilization. By accelerating chemical reactions and improving gas solubility, high-pressure systems can help industries achieve sustainability goals while maintaining competitive performance.

Overcoming challenges

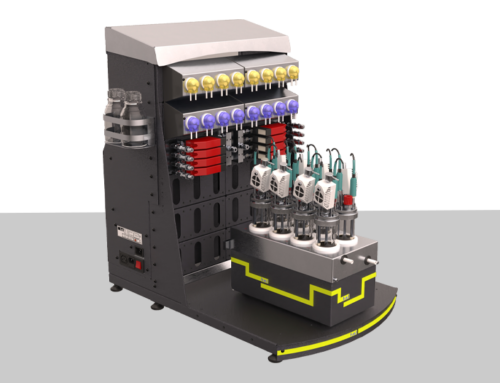

While high pressure offers promising benefits, implementing it also presents challenges. Designing and operating pressure vessels and reactors requires specialized materials and expertise to ensure safety and reliability. Advances in pressure reactor technology, automation, and materials science are addressing these issues, making high-pressure systems more accessible and reliable. Automation technologies streamline process control, reducing human error and improving efficiency. These innovations not only lower operational risks but also help businesses achieve a faster return on investment.

Conclusion

Implementing high-pressure conditions allows researchers and engineers to push the boundaries in bioprocessing and chemical synthesis. From accelerating reaction kinetics to allowing innovative microbial cultivation strategies, high-pressure systems are paving the way for a more efficient and sustainable future in basic science and industry.

As technology continues to evolve, the potential for high-pressure applications will only grow, opening doors to innovations that were once thought unattainable.