ChemSCAN | Parallel Catalyst Screening and Development Platform

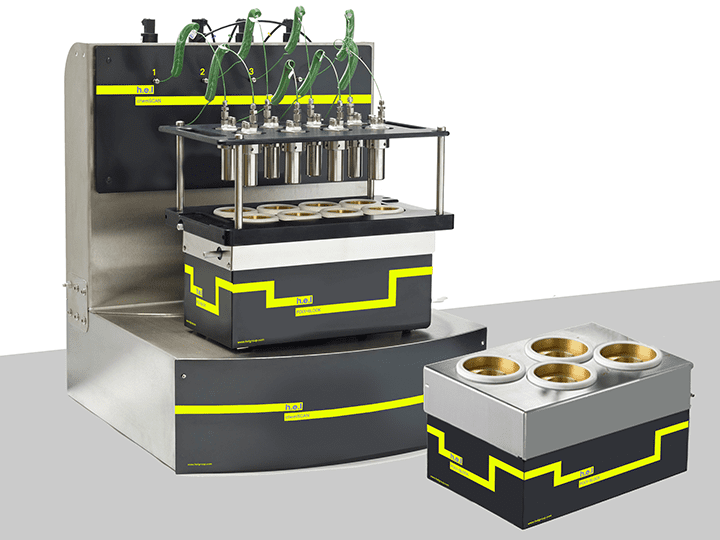

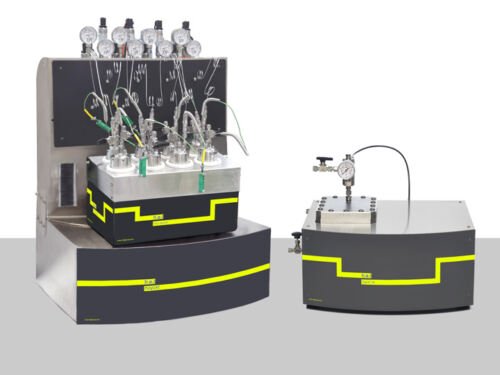

The ChemSCAN is a bench-top, automated parallel catalyst screening platform, designed for the rapid screening of high-pressure reactions and catalysts. The 4 reactor variant, supports reactors ranging from 16ml to 500ml. As with the fully automated ChemSCAN, each stirred reactor is independently controlled and monitored, allowing screening tests to be carried out concurrently and accelerating development time.

Technical Literature

The following is a list of supporting Technical Literature.

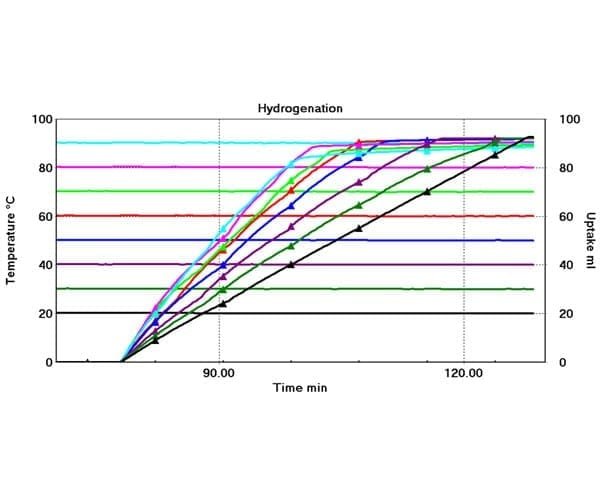

Investigating Hydrogenations at Different Catalyst Loadings using the ChemSCAN

Publications

The following are a list of some technical publications which highlight the use of the equipment.

First Total Synthesis and Structural Confirmation of C13-Butylrubber Oligomers

Fabrizio Minicone Robin Attrill Michael Hodgson Katherine Wheelhouse Adrian Dobbs

01-May-2018

https://doi.org/10.1002/ejoc.201800496(Subscription or purchase maybe required for full access)

Production of Biomass-Based Automotive Lubricants by Reductive Etherification

Jadhav, Deepak Grippo, Adam M Shylesh, Sankaranarayanapillai Gokhale, Amit A Redshaw, John Bell, Alexis T

01-Apr-2017

https://doi.org/10.1002/cssc.201700427(Subscription or purchase maybe required for full access)

Quantitative Differences in Sulfur Poisoning Phenomena over Ruthenium and Palladium: An Attempt To Deconvolute Geometric and Electronic Poisoning Effects Using Model Catalysts

Amy Kolpin,† Glenn Jones,‡ Simon Jones,† Weiran Zheng,† James Cookson,‡ Andrew P. E. York,‡ Paul J. Collier,‡ and Shik Chi Edman Tsang*

01-Dec-2016

https://doi.org/10.1021/acscatal.6b02765(Subscription or purchase maybe required for full access)

Kinetics of hydrogenation and hydrogenolysis of 2,5-dimethylfuran over noble metals catalysts under mild conditions

Ying Lin Louie, Joseph Tang, Alexander M.L. Hell, Alexis T. Bell

01-Sep-2016

https://doi.org/10.1016/j.apcatb.2016.09.046(Subscription or purchase maybe required for full access)

Interstitial modification of palladium nanoparticles with boron atoms as a green catalyst for selective hydrogenation

Chun Wong Aaron Chan, Abdul Hanif Mahadi, Molly Meng-Jung Li, Elena Cristina Corbos, Chiu Tang, Glenn Jones, Winson Chun Hsin Kuo, James Cookson, Christopher Michael Brown, Peter Trenton Bishop & Shik Chi Edman Tsang

01-Dec-2014

https://doi.org/10.1038/ncomms6787(Subscription or purchase maybe required for full access)

Tuning the properties of PdAu bimetallic nanocatalysts for selective hydrogenation reactions

Elena C. Corbos*a, Peter R. Ellisa, James Cooksona, Valérie Brioisb, Timothy I. Hydea, Gopinathan Sankarc and Peter T. Bishop

01-May-2013

https://doi.org/10.1039/C3CY00255A(Subscription or purchase maybe required for full access)

Haloaurate and halopalladate imidazolium salts: structures, properties, and use as precursors for catalytic metal nanoparticles

Christopher J. Serpell‡ a, James Cookson b, Amber L. Thompson a, Christopher M. Brown b and Paul D. Beer

01-Nov-2012

https://doi.org/10.1039/C2DT31984E(Subscription or purchase maybe required for full access)

Etherification and reductive etherification of 5-(hydroxymethyl)furfural: 5-(alkoxymethyl)furfurals and 2,5-bis(alkoxymethyl)furans as potential bio-diesel candidates

Madhesan Balakrishnan, Eric R. Sacia and Alexis T. Bell

01-Mar-2012

https://doi.org/10.1039/C2GC35102A(Subscription or purchase maybe required for full access)

Development of Scaffold Synthesis for the Preparation of New Insulin-Like Growth Factor 1 Receptor Inhibitors

Ilaria Candiani, Germano D’Arasmo,* Franco Heidempergher, and Attilio Tomasi

01-Jan-2009

https://doi.org/10.1021/op8002536(Subscription or purchase maybe required for full access)

Testimonials

ChemSCAN

We are happy to confirm that HEL has supplied us with two high pressure reactor systems with automation. These systems are used for the screening of catalysts and/or different reaction conditions in hydrogenation and hydroformylation reactions. We have been using one device with eight autoclaves during the last 8 years or so, and we are very satisfied with it. The handling and programming is quite easy. The graphical evaluation of data allows us to get an overview about the process in each autoclave. The cooperation and service provided by the employees by phone or e-mail is plain sailing. It is for this reason that we bought a second HP ChemScan with four autoclaves in 2010 which was upgraded recently to an eight-autoclaves-device. It allows a larger variation of parameters and also the graphical evaluation of the results has been further improved.

This apparatus has many advantages. You have a good control of the temperature and pressure and you can follow the gas uptake on the monitor with good accuracy. The software is easy to use, with all commands for one run resumed in one program. The interface of the software is pleasant looking with a good view of all parameters. The reaction can be followed via the graphics, with the possibility of changing the scale of the graphs at any time. Reactors can be easily placed and removed. Handling the reaction mixtures before and after the reaction is quite simple.

University Joseph Fourier - France