Bioprocess development is a complex and multifaceted task that requires the consideration and analysis of various factors to succeed. From selecting the right organisms to choosing the right scale for the process, each step is pivotal in optimizing the fermentation and achieve economic efficiency.

Fermentation has been part of human processes since the dawn of time, but as it undergoes a second golden era, it is crucial to address the challenges associated with process design, quality assurance, and equipment management. In this blog post, we explore the key considerations to ensure that fermentation processes are efficient and scalable, highlighting the main challenges and how to overcome them.

1. Selecting the Right Organism

Choosing an organism suited to generate the desired product can be complex and fraught with compromises. As a general rule, especially for complex molecules, the more similar a cell is to the species that produced it originally, the easier it would be, especially when molecule modifications are necessary. However, animal cells are more fragile and harder to grow, and bacteria, yeast, or fungi are preferred over cell culture. Microbial fermentation is more advantageous due to several reasons: shorter expression time, easier large-scale expression, and smaller variation between batches. Additionally, microbial cells are more easily genetically modified, making them great targets for metabolic engineering, helping to increase the process’s yield. As we can see, choosing an organism requires further consideration and evaluate whether the molecules produced in the organism need modification and if our strain can perform such modifications. Certain products can also be toxic to the cells, potentially inhibiting their growth. In-depth knowledge is fundamental to guaranteeing a successful bioprocess, which should balance growth rate, resilience, and compatibility with desired product traits. This includes high-throughput technologies, which reduce time and costs.

2. Designing scalable process

Scaling a small lab process to an industrial scale presents major obstacles in maintaining product consistency. To achieve this, the process requires robust and stable microbial strains, able to withstand the conditions at large scale, ensuring reproducibility. Small-scale experiments in bioreactors help to establish process characterization. It is not common that small-scale conditions translate direction to larger scale, as aeration, mix, and heat transfer are directly impacted by the size and geometry of vessels, and as such, exhaustive analysis, simulation, and modeling are required to avoid issues at the plant scale.

Operation mode is another variable that needs considering when designing the process. Batch fermentation is common; however, it can result in low yield but fast turnaround. Fed-batch can prolong the log phase, increasing biomass and production of primary metabolites. Continuous processes take longer but generate product continuously, but they avoid set-up and clean-down stages.

3. Creating consistent ideal conditions

Biological systems operate within narrow optimal conditions, making it crucial to maintain key parameters within specific ranges. Even small deviations can significantly impact microbial growth and product yield. These critical parameters include temperature, pH, and dissolved oxygen. Agitation plays a crucial role in ensuring even physico-chemical conditions, maintaining homogeneity, and facilitating efficient heat transfer. Since fermentation generates heat as a byproduct, its effective dissipation is essential to prevent temperature fluctuations that could disrupt microbial growth rates and product yield.

Additionally, enhancing gas solubility through pressurized reactors can further promote microbial growth, though careful pressure control is vital for equipment safety and process stability. Oxygen transfer also demands meticulous management, as it is critical for aerobic organisms and harmful to anaerobic ones, making the maintenance of appropriate oxygen levels fundamental throughout the process.

4. Achieving viable high-quality products

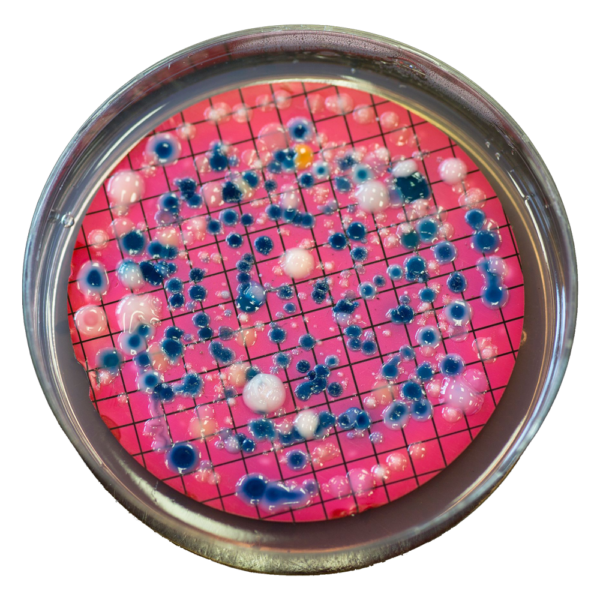

Maintaining consistency among batches and complying with strict quality standards is difficult. This task becomes even more challenging at large scales, where inhomogeneities might occur. In order to achieve uniformity, strict control and stringent quality control processes are required.

Additionally, plant scale often involves increased risks of contamination due to a combination of larger volumes, longer production times, and increased handling. To avoid this situation, it is important to develop an appropriate design, including keeping all parts that require aseptic conditions connected, online sterilization, and control systems.

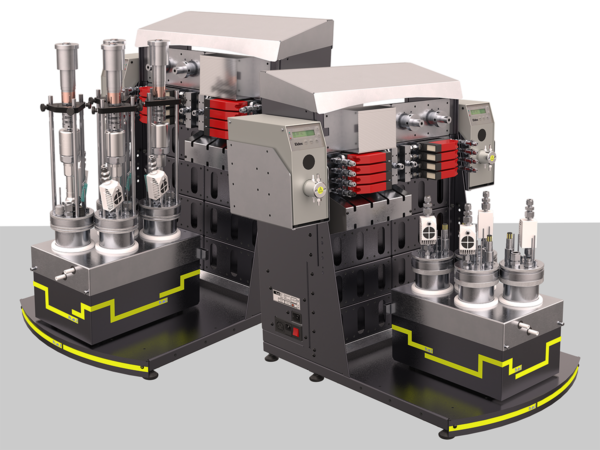

Automation can play a fundamental role in achieving consistency, reducing human error, and increasing accuracy. It is true that it could be costly at the beginning, but it quickly amortizes with low operational costs.

5. Managing Operational and Equipment Strain

Industrial fermentation can put significant strain on vessels as well as other parts of the system. This situation is worsened when microorganisms require extreme conditions, such as extreme pH or high pressure, or if corrosive byproducts are generated during the fermentation process (e.g organic acids, or siderophores)

Maintaining the integrity of the equipment is, hence, paramount. Utilizing materials that are compatible with the conditions becomes imperative when working with microorganisms. This, in turn, will ensure the longevity of the equipment, that the process is safe to run, and that the yields are consistent over time.

Achieving the full potential of fermentation processes

Achieving successful fermentation requires a holistic approach that balances biological, chemical, and operational considerations. Bioprocesses can achieve optimal yields and ensure product consistency by choosing the right organisms, designing scalable and efficient processes, and maintaining strict control over physicochemical conditions. Additionally, managing equipment and implementing automation can further enhance the reliability to create processes with economic efficiency. With these strategies in place, researchers and manufacturers can not only overcome the challenges of fermentation but also achieve innovative and sustainable production.

Sources

- https://www.susupport.com/knowledge/fermentation/challenges-microbial-fermentation-manufacturing

- https://www.gmi-inc.com/large-scale-fermentation-challenges-and-solutions-with-gpc-bio/?srsltid=AfmBOoqFtFd1tUr6yqzLeKtdOQaIrQbmLH2seowF862zWBXeTCduJjs3

- https://www.neonickel.com/technical-resources/fermentation-vessels-materials-challenges-and-alloys

- https://www.ingenza.com/blog/fermentation-problems-and-how-to-solve-them/