The growing demand for efficiency in chemical synthesis within industrial processes like drug discovery has led to an increased interest in automation. High-throughput screening automation can play a fundamental role in finding the optimal conditions for a reaction, enabling industries to accelerate the discovery phase while ensuring reproducibility and accuracy.

Advanced manufacturing has been highlighted as one of the top trends in the industry in 2025, incorporating additive technologies, digitalization, and automation. Advancements in these fields can help overcome some of the bottlenecks, such as workforce shortages and the need for extensive employee training. The integration of automation solutions into high throughput screening is posed to aid companies in improving efficiency, reducing human intervention, and streamlining operations.

Challenges in Traditional Screening

In opposition to automated screening, the use of manual approaches is both time and resource-intensive, requiring operators to evaluate various parameters in order to optimize chemical synthesis processes. Parameters that require evaluation include pressure, pH, temperature, and catalysts, just to mention a few. As we can see, the process demands a significant number of experiments, given the possible combinations. This makes manual methods highly impractical.

Manual screening requires personnel to prepare, execute, and analyze experiments, making it prone to human error. Errors in testing not only delay results, but also lead to additional resource consumptions, requiring repetition. These inefficiencies make manual screening methods unsuitable for current industrial processes, which need speed, accuracy, and reproducibility.

Automation as a solution to improve screening methods

High throughput screening automation is quickly becoming a crucial component in the optimization phase. Automating testing procedures not only improves the efficiency of this phase but also helps maintain consistency and reproducibility. Some of the key benefits of automation include:

- Increased Efficiency: automated systems are capable of simultaneously test multiple reaction conditions, reducing the time required in the optimization process.

- Reduced Human Intervention: automation minimized the need for manual handling, as such reducing the likelihood of human errors and consequently improving the reliability of the results.

- Enhanced Accuracy and Reproducibility: reduced human involvement ensures that experiments are performed with precision, which results in consistent and repeatable results.

- Improved Scalability: tight control linked to the use of automation can aid in the process of scale-up, facilitating a seamless transition between the different stages of development.

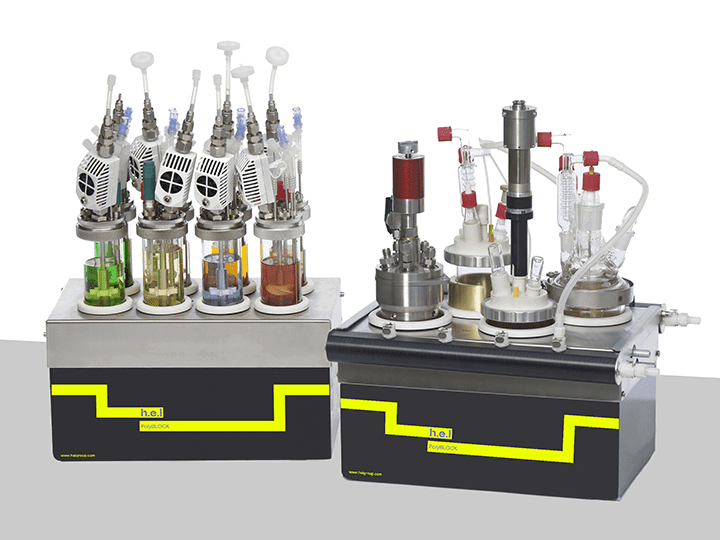

As we can see, the combination of automation and parallel synthesis can enhance not only the discovery phase but also the optimization and even the first steps of the scale-up. Reactors, particularly when independently controlled, enable simultaneous testing of different conditions, drastically cutting down the amount of time required. Additionally, the possibility of operating multiple reactors under identical conditions enhances reliability by reducing variability in replicated experiments,

As chemical synthesis moves from small-scale research towards industrial production, it becomes a priority to evaluate not only the viability but also the safety of the chemical processes. Automation ensures that all the tests required to achieve such safe conditions are conducted under controlled and reproducible conditions, facilitating a smoother transition and avoiding undesired surprises.

Current advancements in Automation

Recent advances in automation technology have introduced innovative solutions which can enhance the throughput in screening in chemical synthesis. Some of these key automated innovations include:

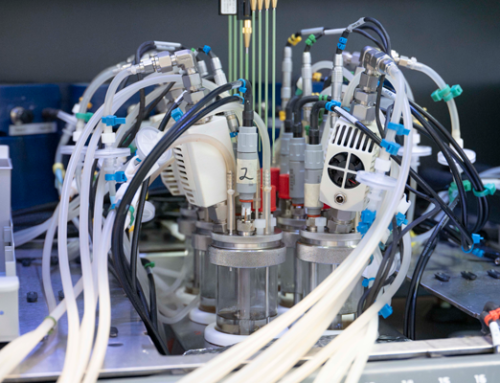

- Automated Reactors: These systems enable real-time monitoring and control of the reaction conditions, which allows for precise adjustments to optimize chemical synthesis. As mentioned previously, automation and reduced manual handling ensure highly reproducible results.

- Software Control: Advanced software solutions allow live measurements, facilitating data collection and analysis. Feedback loops can swiftly correct detected variations from optimal conditions. An effective hardware-software integration can provide comprehensive insights into the reaction performance and increase its efficiency.

- Robotic systems: the use of robotic implements and liquid-handling systems can improve the precision and speed of sample preparation and reagent addition, increasing accuracy and throughput.

The implementation of these cutting-edge automation solutions can significantly increase the efficiency and throughput of the screening and optimization phases in chemical processes.

Embracing the Future of Automation in Chemical Synthesis

The adoption of automation to achieve high throughput in screening is increasingly becoming an imperative necessity for industries looking to remain competitive. As industrial processes become increasingly complex, automation arises as a tool needed to optimize chemical synthesis efficiently and effectively. Embracing automation solution brings benefits such as improved accuracy, enhanced scalability, and reduced operational costs.

Automation is set to play a critical role in the future of chemical synthesis, included drug discovery among other industrial applications. By integrating automated systems, businesses can achieve higher throughputs, reduce errors and mistakes linked to manual handling, and ensure reliable, reproducible results. Investing in automation today will not only improve current screening methods but also pave the way for more advanced and efficient chemical synthesis processes in the future.