Customizable solutions for your process development chemistry

The best solutions for your process R&D needs, including demanding high-pressure and, high-temperature chemistry, calorimetry, and crystallization studies. Our suite of automated, software-controlled instruments includes everything needed for safe and reproducible process chemistry as your projects go up in scale.

Our proprietary software manages this comprehensive range of reaction systems for chemical research, development, optimization, and scale-up. For a better user experience and increased productivity, use labCONSOL® for temperature control, overhead stirring, data recording, and so much more.

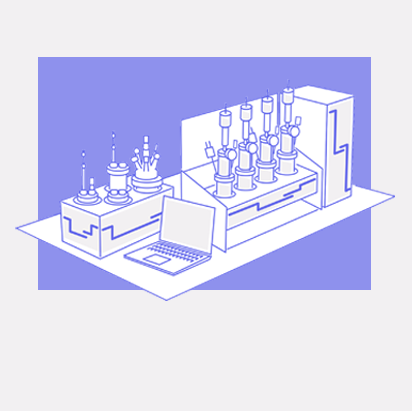

This compact and versatile automated platform supports 8 independently controlled reactor zones. Ideal for parallel synthesis, with a modular design, you can easily expand or adapt for all other process development needs. Designed for optimal productivity in limited-space locations.

Features:

Ideal for Small-scale Process R&D, Reagent Screening, and Design of Experiment

- Compact parallel system with minimal footprint

- Up to 8 software-controlled reaction zones

- Independent temperature and stirring control

- Reactors available in glass, Stainless Steel and Hastelloy

- 1-200 mL

- Up to 200 ⁰C reaction temperatures

- Use any combination of reaction vessels on one platform

- Automatic, user-configurable hazard detection and shutdown procedures as standard

Expandable options:

- High-pressure

- Low temperature

- Turbidity measurements for crystallization studies

- Calorimetry

- Controlled liquid and gas additions

- Range of other sensors (e.g., pH, redox, dissolved oxygen)

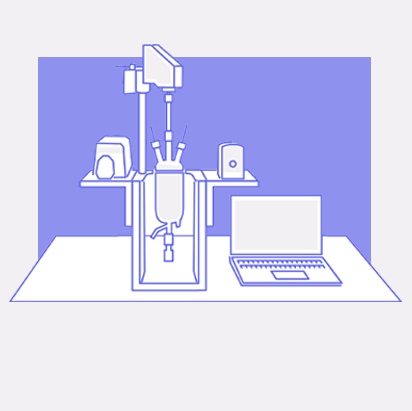

Easily reduce process development time and optimize reaction parameters with these cleverly combined parallel platforms. Ideal to investigate multiple synthetic routes and optimal conditions for scale-up. Automatic, in-reaction data recording delivers meaningful and reproducible results. This configuration offers high functionality for the limited bench space it requires.

Features:

Ideal for Small-scale Process R&D and Design of Experiment

- Compact parallel or linear parallel system

- Up to 4 software-controlled reaction zones

- Independent temperature and stirring control

- Reactors available in glass, Stainless Steel and Hastelloy

- Up to 500 mL

- Up to 200 ⁰C reaction temperatures

Expandable options:

- High-pressure

- High temperature with AutoMATE (up to 400 ⁰C)

- Low temperature

- Turbidity measurements for crystallization studies

- Calorimetry

- Controlled liquid and gas additions

- Range of other sensors (e.g., pH, redox, dissolved oxygen)

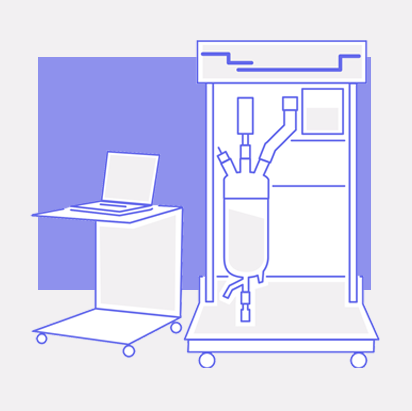

This highly configurable, jacketed lab reaction system is software controlled to provide reproducible results and minimize human error. Explore safe and efficient reaction scale-up and mitigate any thermal and pressure hazards. Optimize reaction efficiency by studying the effect of parameters such as stirrer design, addition rate, mixing regime, and other operating conditions.

Features:

Ideal for Technology transfer for scale-up and Reaction calorimetry

- Modular and highly adaptable system

- Jacketed reactor with automation

- Available in glass, Stainless Steel and Hastelloy

- Up to 5 L

- Automatic, user-configurable hazard detection and shutdown procedures as standard

Expandable options:

- High-pressure

- Turbidity measurements for crystallization studies

- Controlled liquid and gas additions

- Calorimetry

- Range of other sensors (e.g., pH, redox, dissolved oxygen)

This highly configurable jacketed lab reactor is software controlled to provide reproducible results and minimize human error at pilot scale. Handling up to 20 L reactions, it can closely mimic production scale conditions

Features:

Ideal for proof-of-concept experiments prior to manufacturing

- Modular and highly adaptable system

- Jacketed reactor with automation

- Available in glass, Stainless Steel and Hastelloy

- Up to 20 L

- Automatic, user-configurable hazard detection and shutdown procedures as standard

Expandable options:

- High-pressure

- Turbidity measurements for crystallization studies

- Controlled liquid and gas additions

- Range of other sensors (e.g., pH, redox, dissolved oxygen)

Speak to one of our specialists today to find out more!

Having confidence that new equipment will meet your needs is so important. That’s why H.E.L works closely with clients to create individual solutions that are a perfect fit for them, their location and budget.

That continues as needs change over time. Whether for system upgrades, training new recruits or process support, our dedicated teams and knowledgeable staff are here for you. Contact them any time.

Equipment tailored to your needs

H.E.L has a well-established history of developing tailored, automated reactor solutions for all chemical and pharmaceutical industries. See more of our in-built features and expandable options for your process development chemistry.