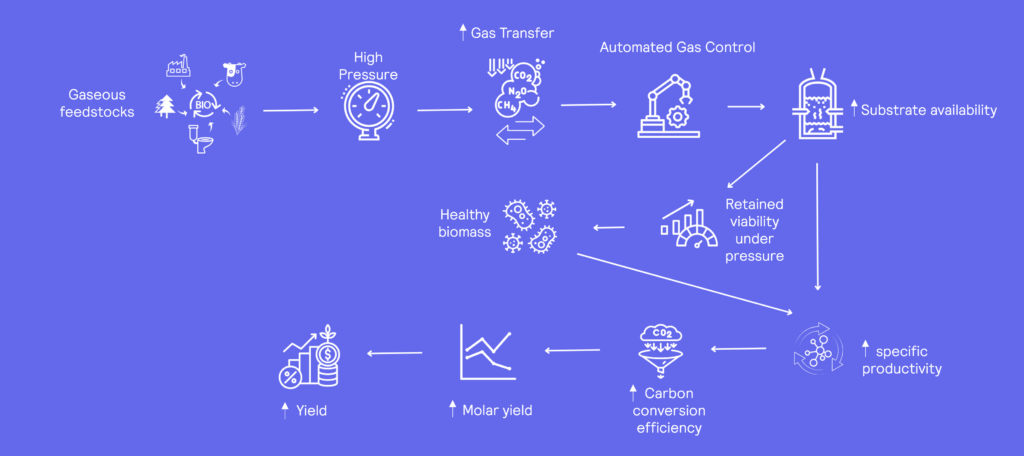

Methods like bioethanol fermentation, alcohol-to-jet (ATJ) and biomass-to-liquid (BtL) require the breaking down or gasification of biomass utilizing biological agents to generate compounds of industrial interest. Traditional fermentation methods often struggle with poor gas solubility, limiting microbial activity, and slowing biofuel and SAF production.

Gas Fermentation Applications

Our biotechnology solutions are utilized across diverse industries where precision, safety, and innovation in biological processes are essential.

Benefits of High Pressure in Gas Fermentation

The high pressure BioXplorer unlocks increased gas solubility of feedstocks improving efficiency of biofuel, SAF & syngas fermentations. Increasing microbial productivity for biofuel and SAF production and boosting yields from syngas, H2 and CO2-based biomanufacturing.

How high-pressure improves biofuel and SAF gas fermentation

Case Study (Garrigues et al., 2019)

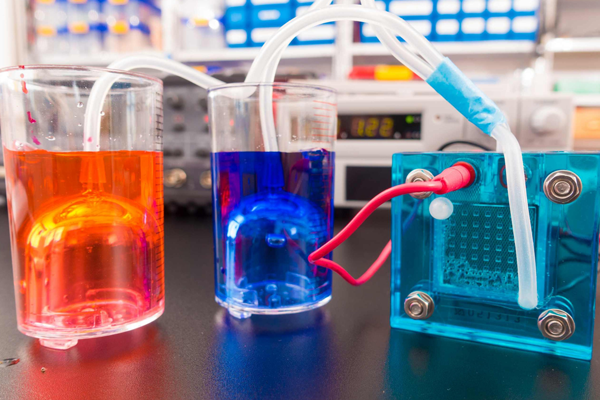

Objective: A research group investigating gas fermentation optimization methods wanted to achieve high concentrations of isopropanol using a genetically modified Cupriavidus necator to ferment gaseous feedstocks CO2 and H2.

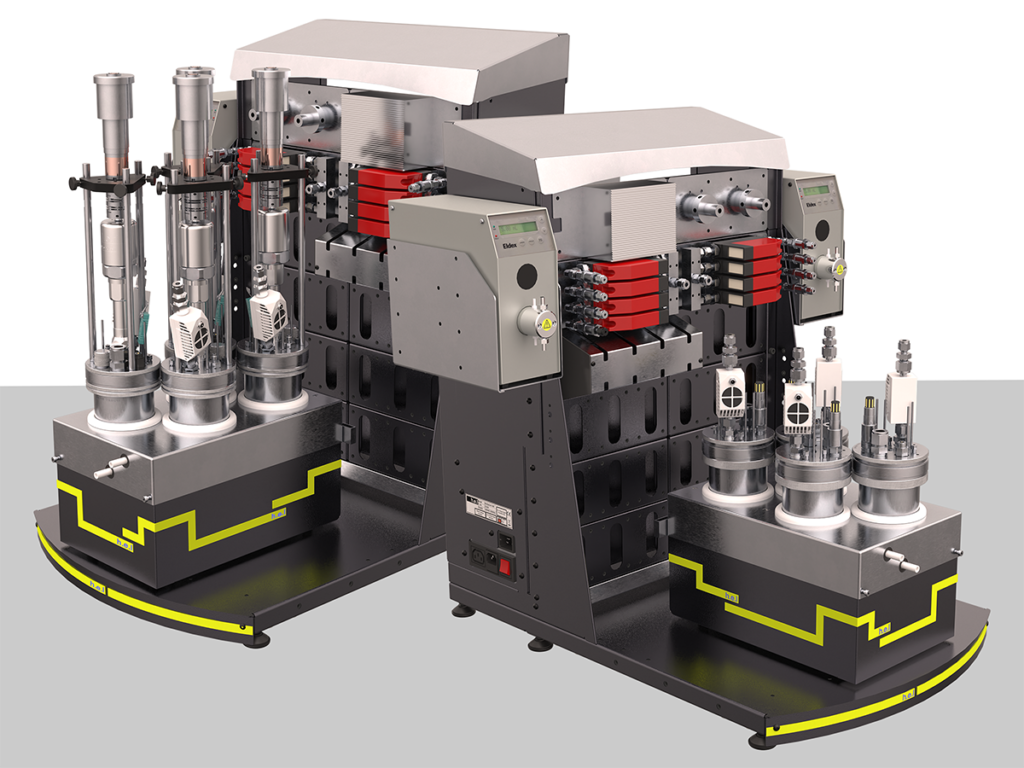

Utilizing a bench scale, parallel bioreactor (100 – 400 ml), the research group required an automated, safe, and highly configurable system to grow an engineered autotrophic strain, with 4 independent gas feeds, providing the ability to generate a high gas-mass transfer to reach high cell and isopropanol titres (g L-1) from CO₂. Ensuring safety levels between 2-6% O₂ for efficient metabolism and avoiding explosive conditions was crucial.

Gases are notoriously difficult to dissolve into liquid. However, pressurized reactors can improve their solubility, increasing feedstock availability. Additionally, hydrogen is highly explosive in the presence of oxygen, so strict control of these gases was fundamental to achieve isopropanol efficiently and safely. The BioXplorer 400P was equipped with three sets of gas feeds: Air, CO2 and H2. A fourth gas feed (N2) was installed as safety system. Various probes and feeds were integrated to monitor and automatically deliver adjustments to the reactor, providing optimal growth and safety conditions for their continuous fermentation.

Isopropanol was produced at comparable levels to traditional methods using a cheaper and more sustainable source CO2 and H2 instead of fructose, decreasing feedstock-derived costs by up to 60%.

Choose the Right Solution

Compare our standard models to find the perfect match for your research and testing requirements.

| Features | BioXplorer 100 | BioXplorer 400 | BioXplorer 400XL |

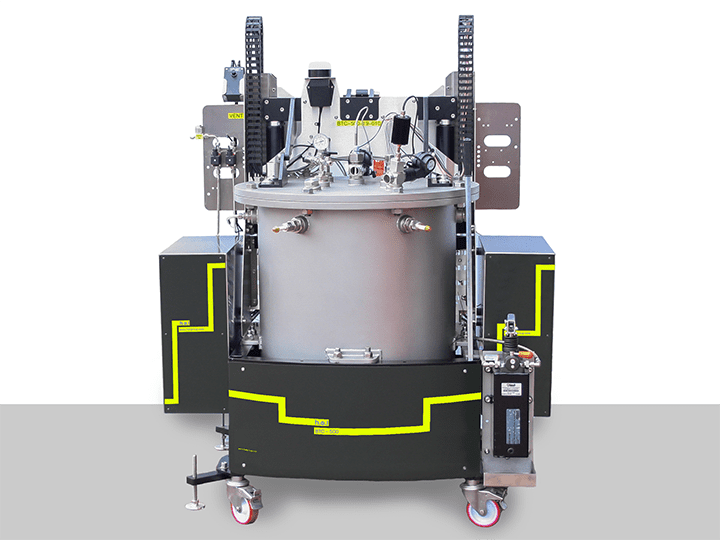

BioXplorer 400P

|

BioXplorer 5000P

|

|---|---|---|---|---|---|

| Type | Low-Volume, Parallel Bioreactor | Small-Scale Parallel Bioreactor | High-Throughput Parallel Bioreactor | High-Pressure, Parallel Bioreactor | High-Pressure, Scale-Up Bioreactor |

| Best For | Semi-Dynamic Gut Simulation / Fermentation | Aerobic / Anaerobic Fermentation | Aerobic / Anaerobic Fermentation | High-Pressure Gas Fermentation/Chemical Synthesis | High-Pressure Syngas Fermentation and Biocatalysis |

| Total Volume (mL) | 200 | 500 | 500 | 500 | 5000 |

| Working Volume (mL) | 50-150 | 120-400 | 120-400 | 120-400 | 400-5000 |

| Temperature (°C) | 0 – 130°C (dependent on system setup) | 0 – 130°C (dependent on system setup) | 0 – 130°C (dependent on system setup) | 0 – 135°C (dependent on system setup) | 0 – 135°C (dependent on system setup) |

| Stirrer Speed | Magnetic: 250 – 1500 rpm | Magnetic: 250 – 1500, Overhead: 20 – 2000 | Magnetic: 250 – 1500, Overhead: 20 – 2000 | Magnetic: 250 – 1500, Overhead: 20 – 2000 | Overhead: 20 – 2000 |

| Reactor material | Glass body, stainless steel lid | Glass body, stainless steel lid | Glass body, stainless steel lid | Stainless steel | Stainless steel |

| Pressure Rating | N/A | N/A | N/A | 10 bar | 10 bar |

| No. of Reactors | 8 | 4 | 8 | 4 | 1 or more |

| Standard Sensors/Probes | Temperature, pH, Dissolved Oxygen | Temperature, pH, Dissolved Oxygen | Temperature, pH, Dissolved Oxygen | Temperature, pH | Temperature, pH, Dissolved Oxygen |

| Standard Feeds | 2 liquid, 1 gas | 2 liquid, 1 gas | 2 liquid, 1 gas | 2 liquid, 2 gas | 2 liquid, 2 gas |

| No. Spargers | 1 | 1 | 1 | 2 | 2 |