After recently starting at H.E.L, I’ve spent a lot of time getting familiar with the PolyBLOCK parallel reaction system. As well as a stand-alone system, the PolyBLOCK is a core component of many of the systems H.E.L supplies. I thought I’d share my observations about the PolyBLOCK and some facts you might find helpful.

- The Basics

- Variety of Sizes

- Modes of Stirring

- Effortless Automation

- Heating and Cooling

- Versatility

The Basics

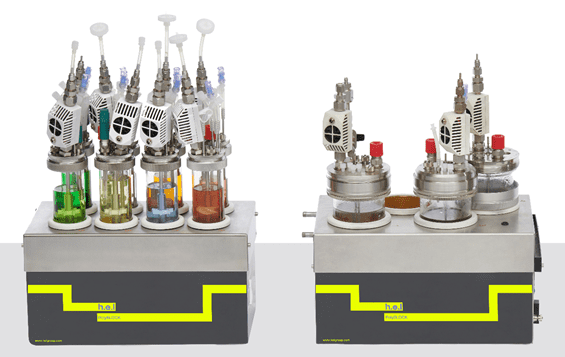

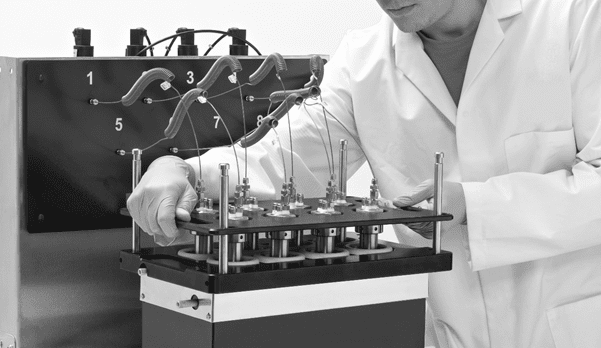

The PolyBLOCK is a compact benchtop reactor used within process development, D.O.E., essential research, and many other applications. PolyBLOCK’s are comprised of four or eight electrically heated reaction zones. It is typically used with glass, stainless steel, or Hastelloy reactors in low-pressure and high-pressure applications.

Variety of Sizes

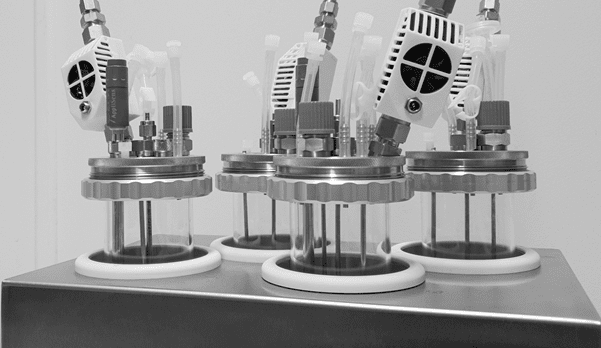

The PolyBLOCK 4 has four independently controlled mantles (reactor zones) typically used with reactor vessels up to 500 mL volume – although special reactors up to 1 L volume are also available. In contrast, the PolyBLOCK 8 has eight mantles, holding reactor vessels up to 200 mL. Aluminum inserts are available for smaller reaction vessels for both the PolyBLOCK 4 and the PolyBLOCK 8. These inserts aid thermal conductivity between the mantles and the reaction vessels, given consistent performance across a wide range of reactor vessels. The inserts also allow different reactors to be used simultaneously in a single block.

Modes of Stirring

Magnetic stirring is available as the default for all PolyBLOCK systems, typically covering the range of 250 rpm up to 1000 rpm, with specific configurations that allow for 1500 rpm. If an application requires more power and more torque, direct suspended agitation is an option.

Both stirring configurations have their benefits. Magnetic stirring can be much quieter and mechanically simpler but may de-couple with viscous liquids. Direct motor stirrers would be well suited for viscous fluids as they can provide greater power, but this will make the handling of the reactors slightly more complicated. A wide range of impellers is available so that the right design can match your experimental work.

Effortless Automation

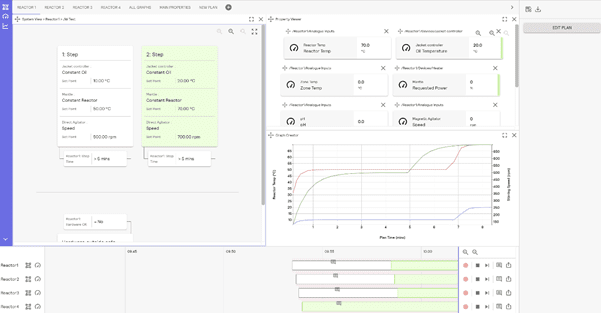

Like all H.E.L products, the PolyBLOCK systems are powered by the labCONSOL® software. labCONSOL allows you to define independent experimental protocols for each reactor or run multiple reactors in identical conditions (or any combination). Before using labCONSOL, I didn’t realize how beneficial it is to have software that allows for simple planning in all reactors. With various reactions running in parallel, I have certainly become more efficient with my use of time.

During the experiment, a wide range of parameters is displayed and monitored for each reactor. Changes in reaction conditions can automatically trigger experimental events (such as changing stirring speed) or initiate safety control measures.

Triggering safety measures is especially helpful if the substances you are working with are hazardous under certain conditions. For example, you can add plans that give a warning if reactors go over a specific temperature, and if temperatures increase further, you can plan a complete system shutdown. Adding these safety plans is beneficial for reactions that may be left unattended for an extended period.

The data display also enables the user to monitor progress in all reactors in real-time on various parameters such as temperature difference (between zone and reactors), stirrer power (in volts), or mantle requested power (as a percentage).

On more than one occasion, I’ve found that the real-time data display is a huge productivity booster. When an experiment goes wrong, I’ve been able to set a new run going in the same day and still get my results when I come in the following day – keeping me on track with my work schedule.

Figure 1. A plan for a PolyBLOCK 4 loaded into labCONSOL® with a graph showing the reaction progression

Heating and cooling

The operating temperature range of the PolyBLOCK is from ambient to 250 °C. This temperature range is helpful for reactions that require high temperatures and to mimic scaled-up processes. The PolyBLOCK also supports the connection of oil bath circulators and/or condensers. Circulators may also be beneficial for experiments that require sub-ambient conditions or effective cooling for crystallization applications. From my experience, I recommend circulators such as Huber or Julabo as both can be directly controlled from labCONSOL and fully integrated into the experimental setup. For further reading on temperature control with the PolyBLOCK, check out the characterization studies I prepared on this.

Versatility

The PolyBLOCK can be used as a stand-alone parallel reactor system; however, it is one of H.E.L.’s most versatile pieces of equipment. The addition of different probes, sensors, pumps, or mass flow controllers to a PolyBLOCK creates systems such as the ChemSCAN, BioXplorer, or CrstyalSCAN. Further modifications can allow for the outflow of reaction samples while reactants are fed into the reactors for continuous fermentations or experiments.

If you’ve got any questions about the PolyBLOCK, please either drop me a line via our contact page or leave a comment below, and I’ll get back to you.