In this section, you will find a library of specific case studies/application notes demonstrating the extensive functionality of how scientists are using H.E.L equipment in all the fields of work, including research, scale-up, and production. These case studies show real results and demonstrate our equipment’s performance in applications for biotechnology, thermal hazards, catalysis, calorimetry, flow chemistry, parallel processing, crystallization, and particle studies. These application notes and case studies are subject to copyright. To use any part of this work, please contact us.

Characterization of the maximum heating performance for the multi-reactor PolyBLOCK 8

In this study, we investigated the maximum temperature heating capacity of the PolyBLOCK 8 when connected to a Silicone oil heating circulator. The results show that the PolyBLOCK 8 can achieve a 90 °C difference between the oil-bath circulator and the internal temperature of both glass and high-pressure (metal) reactor vessels.

Characterization of the cooling performance for the multi-reactor PolyBLOCK 8

This study investigated the temperature cooling capabilities of the PolyBLOCK parallel reaction block with different cooling modes. The solvents used varied in boiling point, heat capacity, and viscosity. The cooling characteristics were evaluated with and without a chilling Silicone oil circulator connected to the PolyBLOCK.

Characterization of the heating performance for the multi-reactor PolyBLOCK 8

This study investigated the temperature control capabilities of the PolyBLOCK parallel reaction block with different control modes, setting a constant reactor temperature or ramping the reactor temperature. Three different solvents were investigated in four different reactors. The solvents used varied in boiling point, heat capacity, and viscosity. Connecting a silicone oil circulator showed optimum temperature control characteristics.

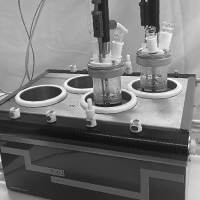

Characterization of the maximum heating capabilities of the multi-reactor PolyBLOCK 4

The maximum heating capabilities of the PolyBLOCK 4 when using a circulator were investigated in this study. The labCONSOL® control software enabled the use of different modes of heating, Heat/Cool Reactor, and Constant reactor. The results show that the PolyBLOCK can achieve a 130 °C temperature difference between the reactor temperature and the circulator temperature.

Characterization of the heating capability for the multi-reactor PolyBLOCK 4

This study investigated the heating temperature capabilities of the PolyBLOCK 4, a bench-top parallel reaction block, when connected to a circulator. Methanol and Silicone oil were the solvents heated in glass and stainless-steel reactors. The labCONSOL® control software enabled the use of different modes of heating, Heat/Cool Reactor, and Constant reactor. Connecting a circulator showed optimum temperature control characteristics.