In this section, you will find a library of specific case studies/application notes demonstrating the extensive functionality of how scientists are using H.E.L equipment in all the fields of work, including research, scale-up, and production. These case studies show real results and demonstrate our equipment’s performance in applications for biotechnology, thermal hazards, catalysis, calorimetry, flow chemistry, parallel processing, crystallization, and particle studies. These application notes and case studies are subject to copyright. To use any part of this work, please contact us.

Chemical Hazard Screening – “Less Is More?”

This article explains how rapid chemical hazard screening can efficiently identify potential reaction risks early, using simple tools to decide when more detailed calorimetric testing is necessary. Combining fast screening with in-depth analysis improves safety while saving time and resources during process development.

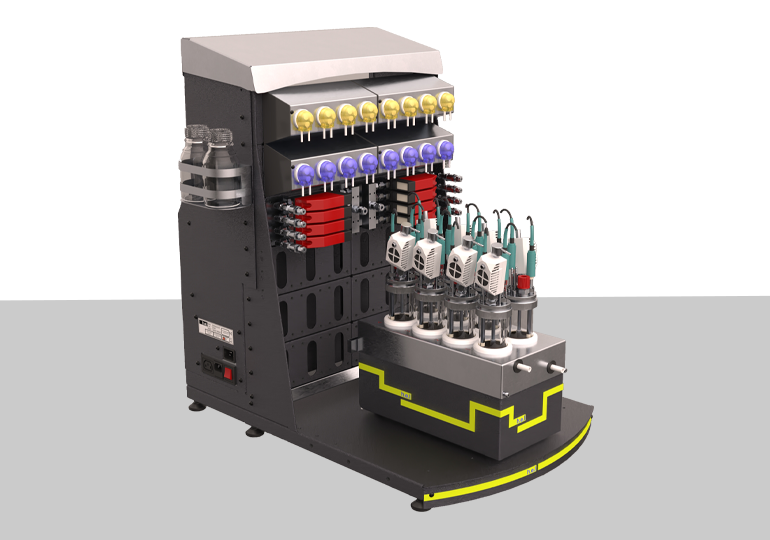

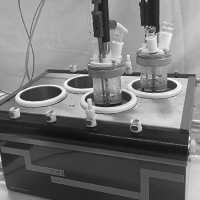

Operating the BioXplorer 100 as a Turbidostat to Maximize High-Density E. coli Cultivation

The BioXplorer 100 can function as a turbidostat to maintain stable, high-density E. coli cultures. Using its BioVIS probe and WinISO-controlled pumps, it adjusts medium flow based on real-time turbidity. A non-linear calibration curve enables accurate cell density measurements at high biomass, supporting reproducible bioprocess development, consistent physiology studies, and controlled experimental evolution.

Application of the INFOGEST Protocol Using the BioXplorer 100 for Automated Digestion Simulation

Digestion involves the breakdown of food into smaller compounds to facilitate nutrient release and absorption along the digestive tract. Studies have highlighted the significant impact of digestion on health, which led to the development of a variety of in vitro digestion protocols that produced non-comparable and often inconsistent results.Studies have highlighted the significant impact of digestion on health, which led to the development of a variety of in vitro digestion protocols that produced non-comparable and often inconsistent results

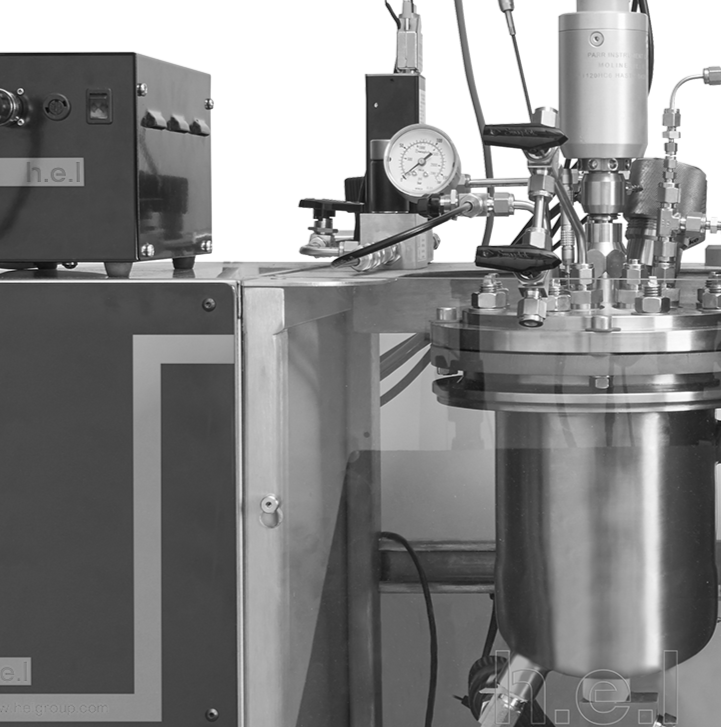

Integration of mass spectrometry to characterize the gas evolution of batteries in thermal runaways using adiabatic calorimetry.

Lithium-ion batteries are an essential energy storage technology, but their increasing energy density raises significant safety concerns. Reports of thermal runaway incidents highlight the urgent need for improved methods to study and mitigate these hazardous events. A key challenge in battery safety research is understanding the gas evolution during thermal runaway, as conventional techniques such as gas chromatography operate under conditions that do not fully replicate high-pressure, high-temperature environments. Here, we present a novel integration of adiabatic calorimetry (BTC-500) with high-pressure mass spectrometry to characterize gas evolution during lithium-ion battery thermal runaway. This approach enables real-time, high-frequency gas composition analysis under extreme conditions, overcoming limitations of conventional gas analysis techniques. Compared to standard gas chromatography, which requires sample transfer and offline analysis, in-situ mass spectrometry provides a direct and dynamic measurement of evolving gases.

Creating Process Safety Data Sheets for Safe Scale-Up in Pharma/API Production

The pharmaceutical industry faces unique challenges as it progresses from R&D bench-scale to plant production, moving from milligram quantities to tons. High-quality active pharmaceutical ingredients (APIs) must be produced in a cost-effective fashion while complying with regulatory requirements for safety and consistency. As such, process safety remains a fundamental pillar to meet these demands and mitigate potential hazards linked to industrial production. In this article, we explore best practices and state-of-the-art tools that can be used to produce Process Safety Date Sheets (PSDS).

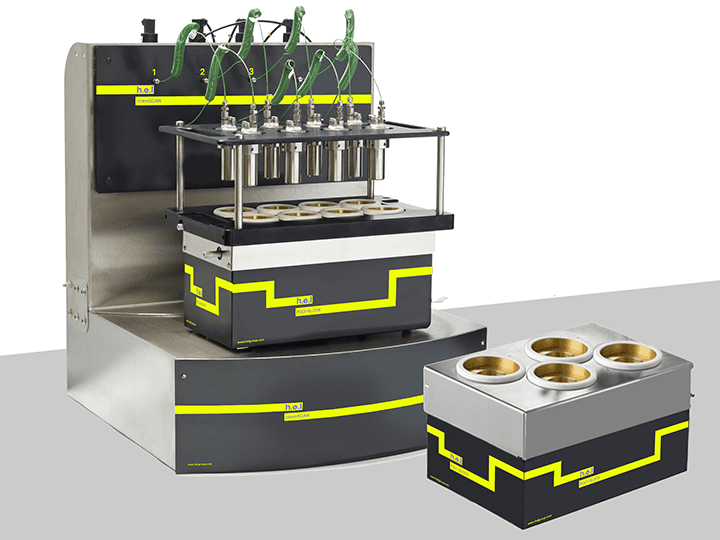

Identifying the best rhodium-modified catalyst and the best reaction conditions with ChemSCAN for the synthesis of aroma compounds

In the perfumery industry, there is a constant need to provide compounds imparting novel organoleptic notes. In this study, a ChemSCAN is used to investigate the hydroformylation of the substrate 4,4-dimethyl-1-vinylcyclohexyl acetate as a precursor for the desired 3-(cyclohex-1-en-1-yl)propanal derivative. Fast parallel trials allowed for the identification of the most active and selective modified rhodium catalyst. Subsequent concurrent experiments enabled the evaluation of different catalyst loadings and minimized the amount of solvent employed.

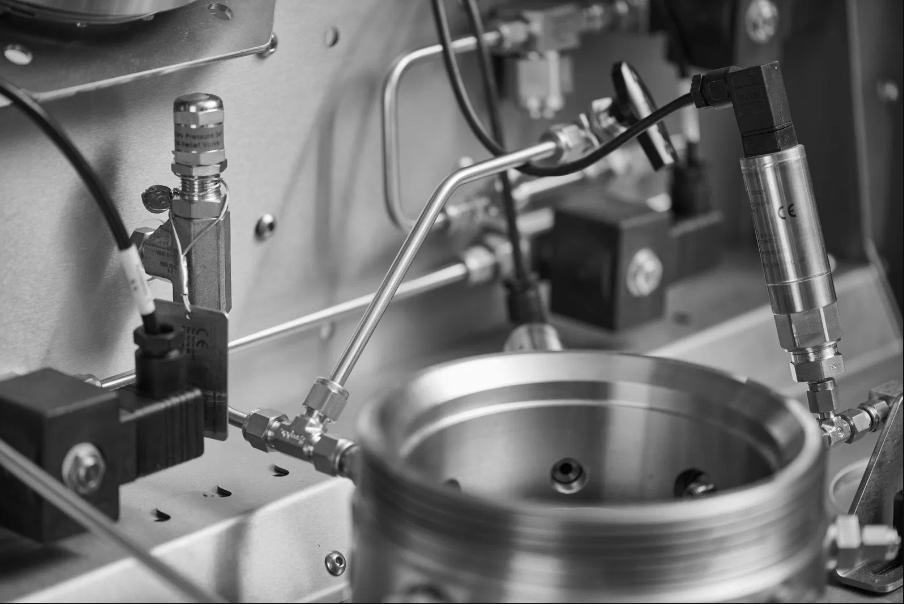

Calorimetric analysis of CO2 absorption in an aqueous N-methyldiethanolamine solution using H.E.L.’s Simular

The study of the CO2 absorption process in alkanolamines is crucial for enhancing gas sweetening and carbon capture technologies, which are essential in reducing greenhouse emissions. Alkanolamines, such as N-methyl diethanolamine (MDEA), are favored because of their thermodynamic and kinetic properties that improve CO2 capture efficiency. Understanding the calorimetry of these processes aids in optimizing absorption capacity and energy efficiency. Here, we show the thermodynamic behavior of CO2 absorption in a 30% MDEA solution using H.E.L’s Simular isothermal reaction calorimeter operated in power compensation mode. This finding highlights the potential of Simular as a powerful tool for optimizing CO2 absorption processes, contributing to effective and safe carbon capture technologies, and supporting global climate change mitigation efforts.

Achieving safe conditions for hydrogenation reaction using concentrated raw materials

Hydrogenation involves the addition of hydrogen gases into molecules, transforming bonds (e.g. C=C to C-C). Hydrogen is highly flammable and explosive, and as such, hydrogenation reactions and their products need to be tested in advance. In this application note, we present the thermal behavior of an alkane and alkene involved in the hydrogenation reaction measured in a Phi-TEC I. Results showed that the alkene was susceptible to decomposition reactions when it reached a temperature 238.8 oC, where the alkane did not display such behavior. Phi-TEC I is an adiabatic calorimeter that has shown its capabilities to detect thermal events in reactants involved in risky hydrogenation reactions.

Assessing the suitability of H.E.L’s BTC-500 for small battery testing

The constant pressure from the market to create more powerful batteries can result in unsafe situations. As a consequence, battery testing is crucial to obtain better batteries that can be operated safely. Adiabatic calorimetry is an incredibly powerful tool for identifying the temperature values at which a battery can be operated. The characterization of events, such as thermal runaways, can help identify the risks and establish mitigation strategies. However, choosing the right calorimeters can prove challenging because they are not sensitive enough for small batteries or cannot withstand battery failures. In this application note, we tested a very small battery (LP103035) in a large calorimeter (BTC-500).

Comparison of different calorimetry methodologies using Simular reaction calorimeter

Reaction calorimetry is a fundamental tool in the evaluation of chemical processes by measuring heat exchange. In this study, we compare results obtained from Heat Flow (HF) and Power Compensation (PC) methodologies utilizing H.E.L’s Simular. HF is considered the standard methodology in industry, which tracks temperature gradient across the jacket wall in reactors, whereas PC maintains a stable temperature throughout the process by adjusting and measuring differences in electrical power. We assess the performance of both methodologies using acetic anhydride hydrolysis.

Calorimetry: Heat flow versus power compensations methods

In this note, we compare the fundamentals and operation of two calorimetry methodologies that the Simular performs: heat flow and power compensation. The mathematical calculations to calculate the energy produced or absorbed by the chemical reaction are presented. The last section directly compares both methods in terms of measurements, temperature control, accuracy, and time.

The use of a H.E.L BioXplorer in fermentations of Cupriavidus necator H16 at elevated pressure using CO2 as the sole carbon source

In this case study, the H.E.L BioXplorer was used to evaluate microbial fermentation in either autotrophic mode or heterotrophic mode.

Using the Phi-TEC I in Thermally Unstable Environments

In this study, environmental thermal instability was deliberately introduced while using the Phi-TEC I adiabatic calorimeter for exothermic reaction detection.

Investigating Zinc Oxide-Modified Mordenite as an Effective Catalyst for the Dehydrogenation of Ethanol utilizing the FlowCAT

In this study, the H.E.L FlowCAT was used for the development and optimization of a process for the production of acetaldehyde via the dehydrogenation of bioethanol. This is the first stage toward a multistep reaction, taking ethanol to higher-value chemicals.

Investigating a Sponge Metal Catalysts in a Trickle Bed Reactor for Continuous Hydrogenation Inflow

In this study, the H.E.L. FlowCAT was used to optimize the inflow of the reductive hydrogenation of an aliphatic nitro intermediate using a sponge nickel catalyst in a trickle bed reactor. Once optimal conditions were established, 1.2 kg of reagent was successfully reduced, with a yield of approximately 90% over a period of 19 hours.

Characterization of the maximum heating performance for the multi-reactor PolyBLOCK 8

In this study, we investigated the maximum temperature heating capacity of the PolyBLOCK 8 when connected to a Silicone oil heating circulator. The results show that the PolyBLOCK 8 can achieve a 90 °C difference between the oil-bath circulator and the internal temperature of both glass and high-pressure (metal) reactor vessels.

Characterization of the cooling performance for the multi-reactor PolyBLOCK 8

This study investigated the temperature cooling capabilities of the PolyBLOCK parallel reaction block with different cooling modes. The solvents used varied in boiling point, heat capacity, and viscosity. The cooling characteristics were evaluated with and without a chilling Silicone oil circulator connected to the PolyBLOCK.

Characterization of the heating performance for the multi-reactor PolyBLOCK 8

This study investigated the temperature control capabilities of the PolyBLOCK parallel reaction block with different control modes, setting a constant reactor temperature or ramping the reactor temperature. Three different solvents were investigated in four different reactors. The solvents used varied in boiling point, heat capacity, and viscosity. Connecting a silicone oil circulator showed optimum temperature control characteristics.

Investigating Hydrogenations at Different Catalyst Loadings using the ChemSCAN

In this study, a ChemSCAN is used to investigate the hydrogenation of nitrobenzene with a range of Pd/C catalyst loadings ranging from 4.0 mg to 9.3 mg. The experimental results showed that the hydrogenation reaction rate increases as the amount of catalyst in the reactor increases.

Characterization of the maximum heating capabilities of the multi-reactor PolyBLOCK 4

The maximum heating capabilities of the PolyBLOCK 4 when using a circulator were investigated in this study. The labCONSOL® control software enabled the use of different modes of heating, Heat/Cool Reactor, and Constant reactor. The results show that the PolyBLOCK can achieve a 130 °C temperature difference between the reactor temperature and the circulator temperature.

Characterization of the heating capability for the multi-reactor PolyBLOCK 4

This study investigated the heating temperature capabilities of the PolyBLOCK 4, a bench-top parallel reaction block, when connected to a circulator. Methanol and Silicone oil were the solvents heated in glass and stainless-steel reactors. The labCONSOL® control software enabled the use of different modes of heating, Heat/Cool Reactor, and Constant reactor. Connecting a circulator showed optimum temperature control characteristics.

How to use an isothermal calorimeter to characterize a gel battery

By using the iso-BTC – isothermal calorimeter, coupled with a charge/discharge unit, which is specifically designed for the testing of cells and battery packs. We could characterize a battery’s over a wide range of operational conditions.